Securitron SAM2-24 User Manual

Page 5

PN# 500-10450

Page 5

Rev. B, 02/12

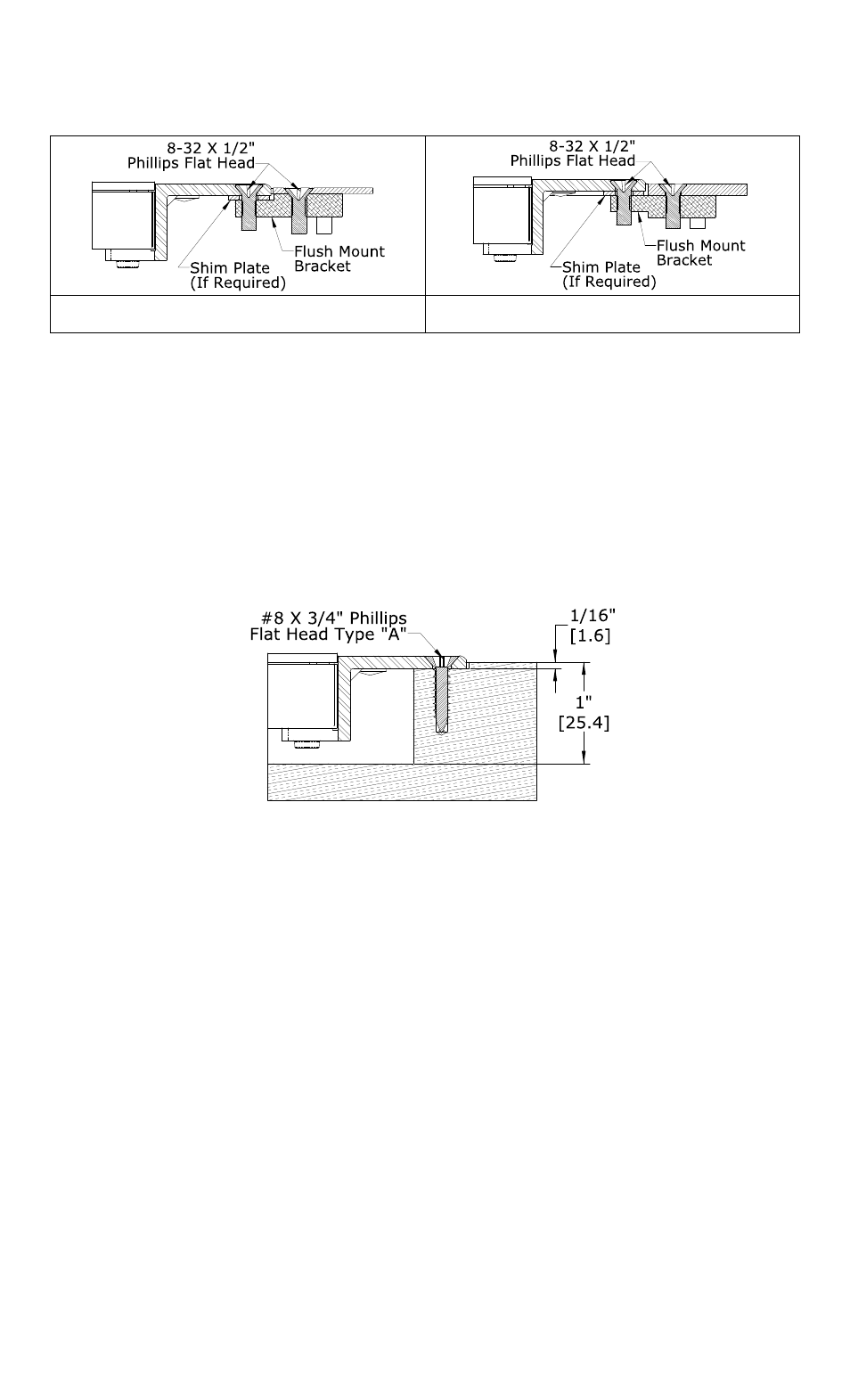

mounting bracket and the flush mount bracket in order to raise the Magnalock above the frame

surface.

Figure 4 - Flush mount bracket mounting

(thin wall frame)

Figure 5 - Flush mount bracket mounting

(thick wall frame)

APPLY THE PROVIDED THREAD LOCKING COMPOUND TO ALL MOUNTING SCREW

THREADS.

5.5.2 Solid Wood Door Frames

Prepare the door frame in accordance with Section 5.4.1.

Place the Magnalock into the cutout area to ensure proper fit. As necessary, perform any filing

or chiseling necessary to ensure the mortised fit. Ensure all necessary holes required to mount

the Magnalock into place as indicated on the template have been provided. The depth of the

mortise cutout is important for proper fit. The minimum depth of the cutout is noted in Figure

6 below and includes enough distance for the required recess depth of 1/16” [1.6mm] of the

mounting brackets. Install the Magnalock using the wood mounting screws as shown in Figure

6.

Figure 6 - Wood frame lock bracket mounting

5.6 Mounting the Strike Assembly

The strike assembly mounting method varies with the type of door being used. The included

template provides preparation and installation information for the various types of doors. The

following sections describe the door type and installation procedures.

The strike bracket assembly has been designed with adjustment features which are intended to

help accurately install and adjust the strike assembly for proper operation. The two L-shaped

end brackets and the idle bracket of the assembly are serrated to provide a secure locking

adjustment of the height of the strike in the door edge. The end brackets have obround slots to

limit the adjustment travel and to support the structure of the assembly. By loosening the

screws at each end, the brackets can be adjusted to the desired mounting height.

The serrations on the brackets are .050” [1.3mm] apart which matches the screw thread pitch

distance that mounts the strike. This feature will be explained during the final adjustment in

Section 5.7. These end brackets may also be inverted to provide for deeper mounting

configurations. See Figure 7 and Figure 8 for adjustable ranges and mounting methods.

THE POSITION OF THE CENTERLINE OF THE STRIKE ASSEMBLY IS CRITICALLY

RELATED TO THE CENTERLINE OF THE MAGNALOCK LOCATION.

5.6.1 Hollow Metal Door (Flush Top)