Securitron IK_Series User Manual

Securitron For Home

Securitron Magnalock Corp.

www.securitron.com

ASSA ABLOY, the global leader

Tel

800.624.5625

in door opening solutions

© Copyright, 2011, all rights reserved

PN# 500-11900

Page 1

Rev. C, 07/11

MODEL IK, IKM INSTALLATION TOOL KIT

INSTRUCTIONS FOR USE

1. DESCRIPTION

The IK contains tools that will improve the speed and quality of model 62 and 32 Magnalock

installations. It also includes additional fasteners and a Tips and Techniques Installation Video.

The IKM is the export version which includes metric fasteners.

2. DRILL GUIDE

The drill guide is the gold colored angle piece. This allows drilling more rapid and accurate pilot

holes for mounting the magnet and strike plate on outswinging doors. It replaces the paper

template provided with the lock. The holes in the guide are sized for use with a 1/8" drill bit and

the guide includes hardened steel bushings so that it will last for many Magnalock installations.

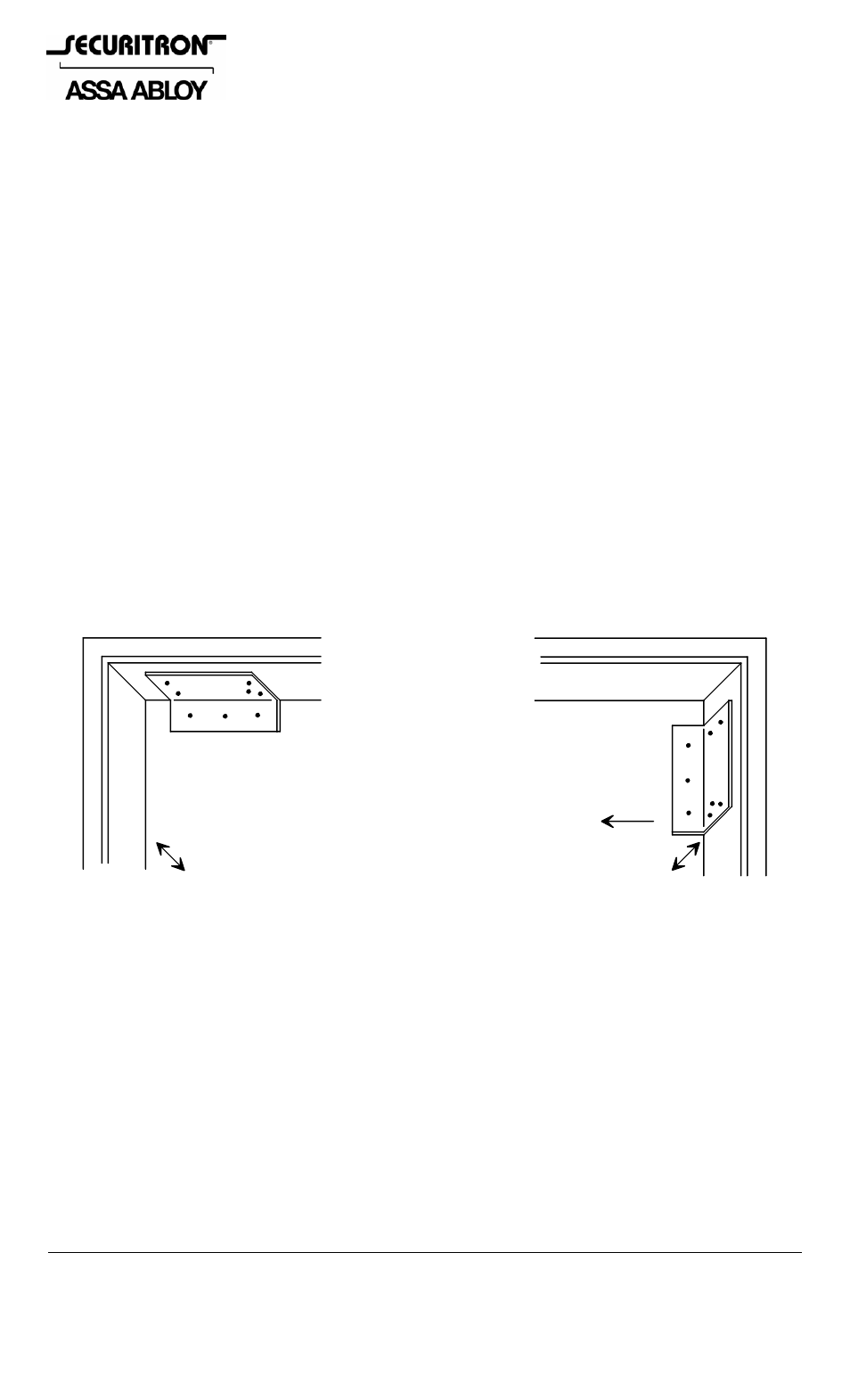

2.1 POSITIONING THE GUIDE

The first point to notice about the guide is that it has two sets of holes: for the 62 and 32

Magnalock. The six 32 Magnalock holes are surrounded by a silver colored ring. The eight 62

holes are "plain". Next, the guide must be placed against the door and frame (with the door

closed). Figure 1 shows the concept of positioning the drill guide for horizontal and vertical

mounting. Note that the 3 "in line" holes are always for the strike plate and it is this set of holes

that must be positioned on the door. Note also that in the drawing, the guide has been moved

in from the corner somewhat. This is to permit easy drilling of the holes nearest the corner.

This distance that the guide should be moved in from the corner will depend on the type of drill

you will be using. You can set this distance by simply positioning the drill against the frame.

FIG. 1: POSITIONING THE DRILL GUIDE FOR HORIZONTAL AND VERTICAL MOUNTING

DOOR

FRAME

HEADER

DOOR

FRAME

HEADER

PLACEMENT OF DRILL

GUIDE FOR HORIZONTAL

LOCK MOUNTING

PLACEMENT OF DRILL

GUIDE FOR VERTICAL

LOCK MOUNTING

SLIDING THE GUIDE IN THESE

DIRECTIONS COMPENSATES FOR

MAGNET MOUNTING SCREWS

ALIGNING WITH FRAME STOP EDGE

SLIDING THE GUIDE IN THESE

DIRECTIONS COMPENSATES FOR

MAGNET MOUNTING SCREWS

ALIGNING WITH FRAME STOP EDGE

THE GUIDE MUST BE SLID 1/10"

IN THIS DIRECTION

WHEN THE LOCK IS MOUNTED

VERTICALLY

The drawing shows an "ideal" door frame because the door stop is wide enough to fully mount

the magnet body. This will not always be the case and you should be prepared to employ

accessory brackets. See the Magnalock instruction manual for descriptions of these brackets.

One problem that brackets cannot solve is if the mounting screws of the magnet body fall on an

edge in the frame or stop. This can be compensated for by varying the number of rubber

washers that stand off the strike plate from the door. The stand off that is set by positioning the

drill guide as shown in Figure 1 is 1/4" (6MM) which is the thickness of two rubber washers.

Magnalocks are delivered with three rubber washers and extras are supplied with the kit so you

can slide the guide farther away from the door and compensate with extra rubber washers. You

can also drop down to one rubber washer by moving the guide 1/8" (3MM) closer to the door.

To accomplish this, obviously the door must be opened slightly. Note also that when you're

using the model 62, it is possible to mount the product with only two magnet mounting screws

(at opposite ends of the magnet). This is not ideal as it sacrifices some rigidity, but two screws

mounted into blind nuts are of adequate strength.