Securitron SAM2-24 User Manual

Page 6

PN# 500-10450

Page 6

Rev. B, 02/12

NOTE: THE SAM2-24 STRIKE ASSEMBLY IS NOT RECOMMENDED FOR USE IN

ALUMINUM OR STEEL FRAMED DOORS THAT HAVE A CHANNEL RECESS AT THE TOP.

FOR PROPER OPERATION IN HOLLOW METAL DOORS THE STRIKE ASSEMBLY SHOULD

BE MOUNTED IN THE FLUSH MOUNT ARRANGEMENT ONLY!

Prepare the door in accordance with Section 5.4.2.

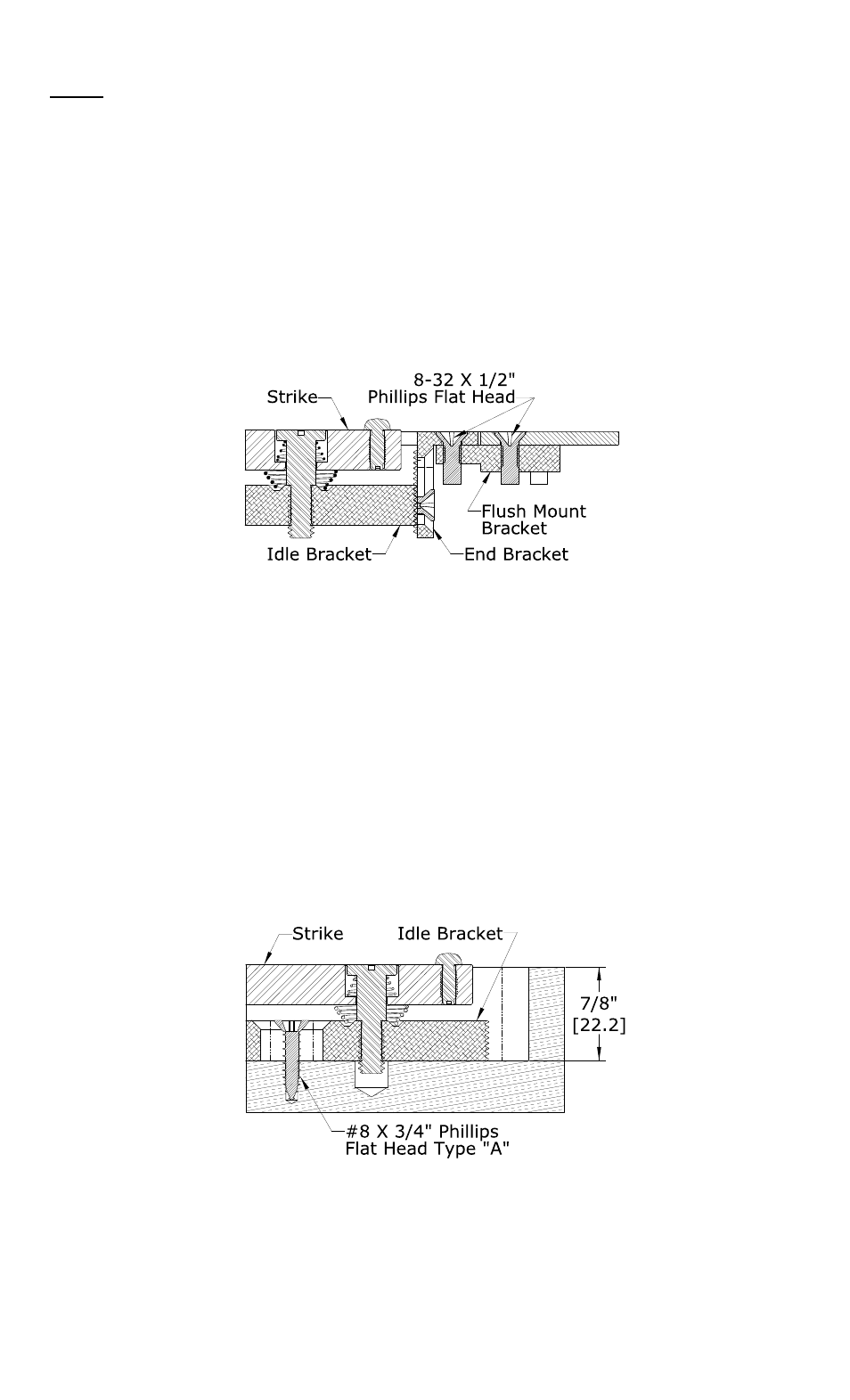

Mounting the strike assembly into a door with flush outside surfaces utilizes the same methods

as mounting the Magnalock into a hollow metal type frame. Figure 7 below shows a typical

installation in a flush type aluminum door. In this process the flush mount brackets are used to

suspend the strike assembly into the door. Make the necessary adjustments to the end brackets

of the strike assembly to set the initial strike height in the door installation. The flush mount

brackets may be installed in either direction (see Figures 4 and 5) to set the appropriate flush

mounting condition, and the provided shim plates may also be used to assist in further

adjustment of the installation. Use a screwdriver and the provided mounting screws to complete

the installation.

Figure 7 - Hollow frame strike assembly mounting

APPLY THE PROVIDED THREAD LOCKING COMPOUND TO ALL MOUNTING SCREW

THREADS.

5.6.2 Hard Core Wood Door

Prepare the door in accordance with Section 5.4.2.

For mounting into hard core (solid) wood doors the strike assembly may be mounted with or

without the end brackets attached. The door cutout requires a mortise area for the strike base

assembly with sizes that are dependent on whether the end brackets are used or not (see

template). The depth requirements are illustrated in Figures 8 and 9. If the installation does

not require use of the end brackets (as shown in Figure 8), the installer must be accurate on

the depth of the cutout. (If the mortised cutout is too shallow it will not allow enough room for

the strike to be adjusted down any lower and the door operation may be hindered. If the cutout

is too deep, shimming may be necessary to adjust the idle bracket height in the installation).

When the end brackets are used, the cutout area requires a minimum depth (shown in Figure

9) and because of the adjustability in the end brackets, cutting the recess too deep will not

affect the installation.

Figure 8 - Wood door strike mounting without brackets