Ransburg, Troubleshooting guide – Ransburg RMA-560 Single_Dual Purge Direct A13364 User Manual

Page 74

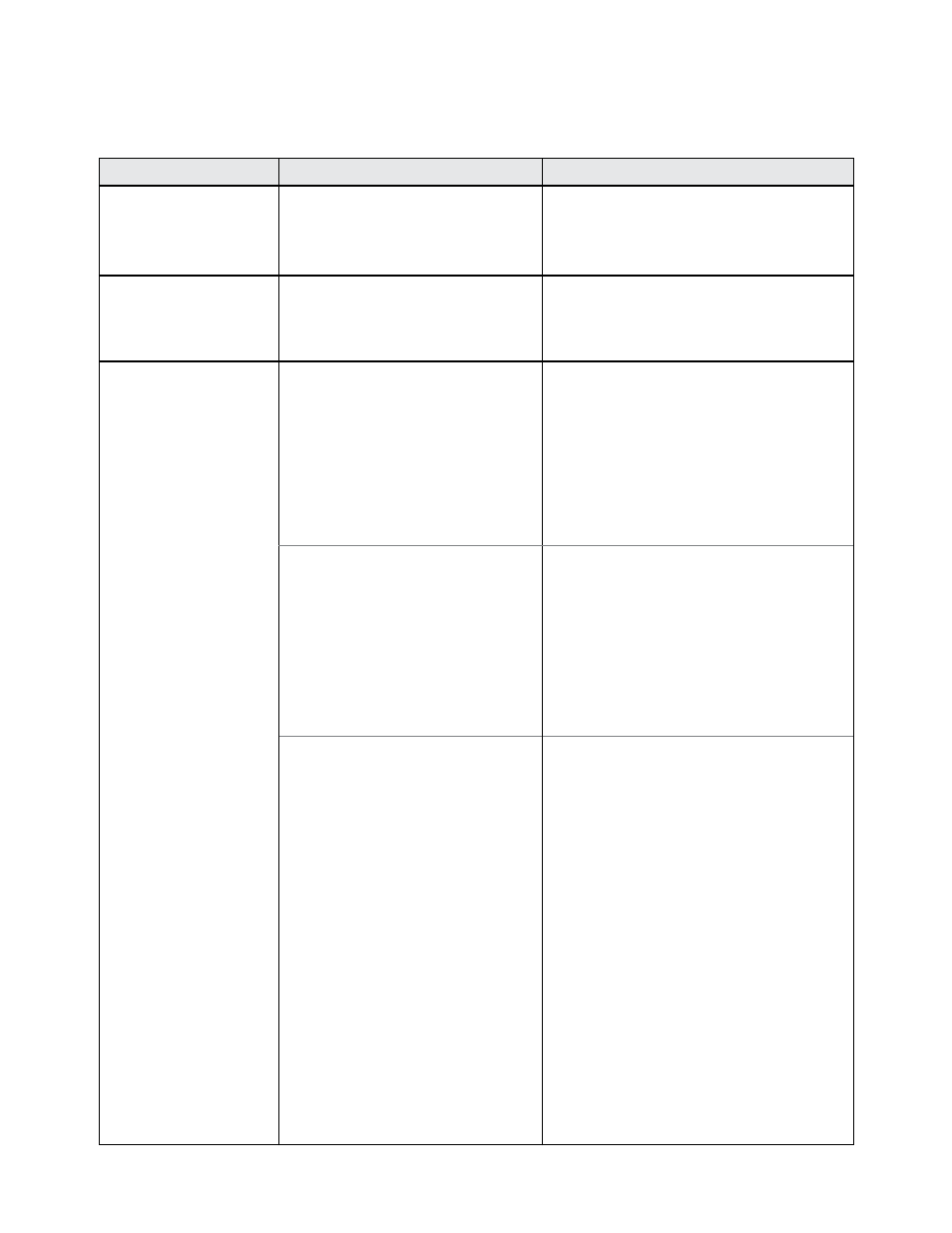

TROUBLESHOOTING GUIDE

(Cont.)

General Problem

Possible Cause

Solution

Turbine Cannot

Attain Desired

Speed

Fluid Leakage In

Fluid Manifold or

Bell Plate

Fluid Leakage

Around Fluid

Valve

O-ring is damaged

Outer diameter of tubing coil is

damaged

O-ring is damaged

Outer diameter of tubing coil

is damaged

Excessive vibration

Low or no bearing air

Loss of fiber optic/no feed

Replace O-ring.

Inspect tubing coil for scratches and replace

if damaged.

Replace o-ring(s).

Inspect tubing coil for scratches and replace

if damaged.

a. Check bell cup for damage.

b. Check bell cup for excessive paint buildup.

c. Bell cup loose - tighten to proper torque.

d. Poor turbine air pressure - plant air.

e. Have manufacturing check bell cup

balance.

a. Check bearing air pressure (minimum

80 psi) (352 kPa).

b. Check filters for contamination.

c. Check for bent or damaged bearing air line.

d. Poor turbine air pressure - plant air.

e. Damaged speed control cards.

Damaged fiber optic sensor, bad cable, too

many splices. Maximum three (3) slices

permitted.

RMA-560 Single/Dual Purge Direct Charge - Maintenance

Ransburg

LN-9278-13

71