Mounting, Electrical and fiber optic connections, Ransburg – Ransburg RMA-560 Single_Dual Purge Direct A13364 User Manual

Page 31

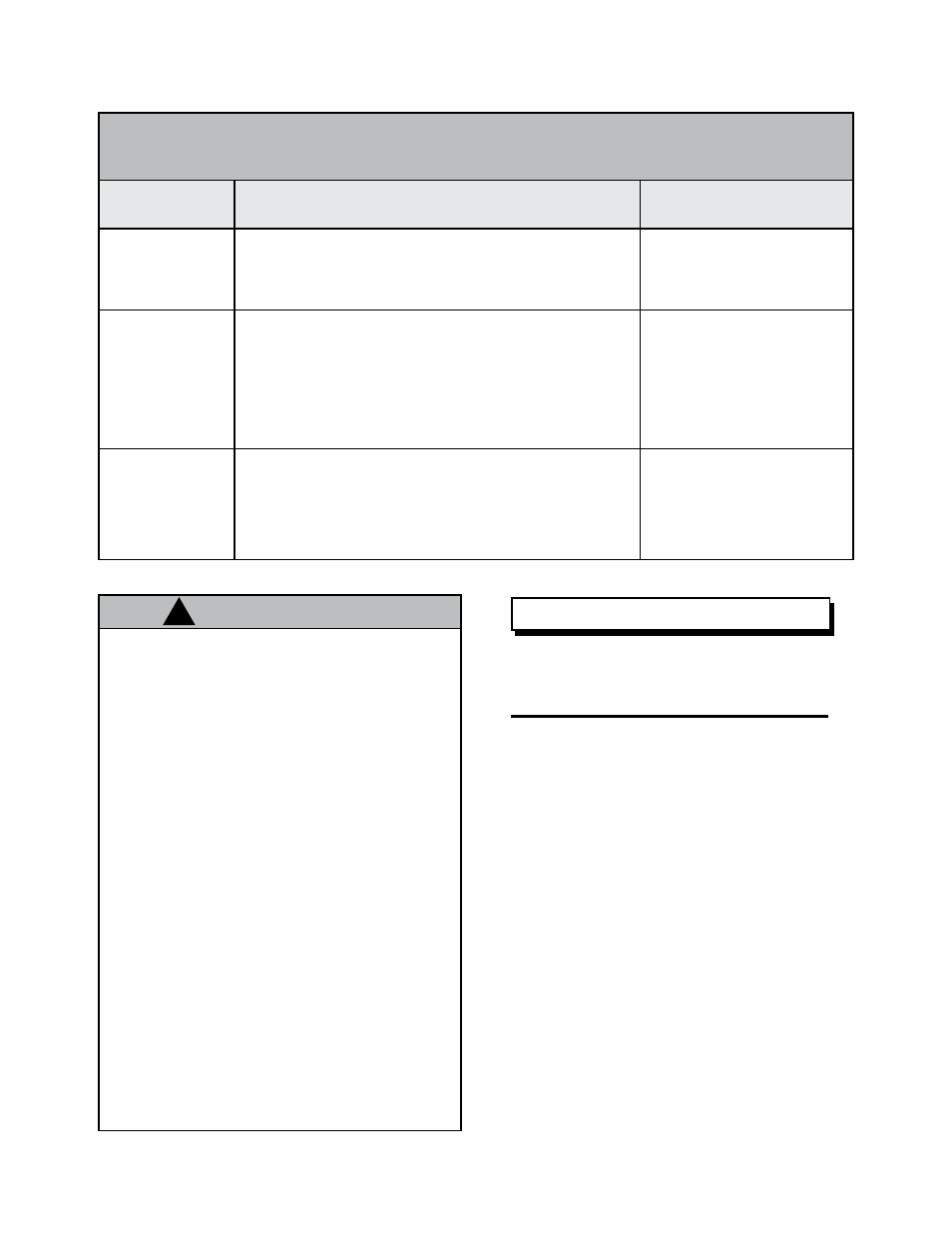

Pre-filter, removes coarse amounts of oil, mois-

ture and dirt. Used upstream of HAF-508 pre-filter

(used in systems with poor air quality.

Pre-filter, coalescing type, 136 SCFM, 98.5% ef-

ficiency particulate removal .3 to .6 micron, max.

aerosol passed 1.0 micron, max. solid passed .4

micron (dependent upon SCFM requirement per

applicator, one HAF-508 can be used with up to

three RMA-560 assemblies).

Bearing air filter, coalescing type,19 SCFM,

99.995% efficiency particulate removal .3 to .6 mi-

cron, max. RMA-560 passed .6 micron max. solid

passed .2 micron (one per RMA-560)

NOTE

C A U T I O N

!

AIR FILTRATION REQUIREMENTS WHEN USED WITH A11065-05

AIR HEATER OR NO AIR HEATER

Ransburg Filter

Model No.

Repacement Element Part No.

Description / Specifications

HAF-15 Element One

HAF-38 Elements,

Carton of 4

RPM-33 Elements,

Carton of 8

HAF-503

HAF-508

RPM-418

Air must be properly filtered to ensure

extended turbine life and to prevent con-

tamination of the paint finish. Air which is

not adequately filtered will foul the turbine

air bearings and cause turbine failure. The

correct type filters musts be used in an

RMA-560 system. The filter elements must

be replaced regular schedule to assure

clean air.

It is the user’s responsibility to ensure

clean air at all times. Turbine failure re-

sulting form contaminated air will not be

covered under warranty. If other filters are

incorporated in the system, the filters to be

used must have filtering capacities equal

or better than those shown in “Air Filtration

Requirements Charts.”

The user must ensure the bearing air

supply is not inadvertently turned off while

the RMA-560 air motor is turning. This will

cause air bearing failure.

Each applicator must have its own fil-

ter for bearing air. Recommended: RPM-

418 or equivalent.

MOUNTING

The RMA-560 is equipped with a quick disconnect

assembly. The quick disconnect feature consists

of a robot plate which is permanently attached

to the robot through a wrist adapter plate, and a

mating bell plate which is a part of the RMA-560

atomizer assembly. The atomizer is secured to

the robot plate with a threaded retaining ring. A

plastic or metal ring is available.

ELECTRICAL AND FIBER OPTIC

CONNECTIONS

The fiber optic connection is made on the back of

the atomizer’s robot plate. The fiber optic cable

comes pre-assembled with connectors that are

RMA-560 Single/Dual Purge Direct Charge - Installation

Ransburg

LN-9278-13

28