Fluid connections, Typical installation, Ransburg – Ransburg RMA-560 Single_Dual Purge Direct A13364 User Manual

Page 32: Fluid tubing connection requirements

FLUID TUBING CONNECTION REQUIREMENTS

Pressure (Maximum)

Fixed Atomizer

Paint Line (P)

Cup Wash Solvent Line (SOL)

Dump Line (DL)

8mm OD X 5mm ID

8mm OD X 5mm ID

10mm OD X 7mm ID Nylon

200 psi max. (1379 kPa)

150 psi max. (1033 kPa)

200 psi max. (1379 kPa)

secured in place by set screws tightened from the

side of the robot plate. An adequate ground must

be provided to the mounting plate to ensure that

fluid fittings, etc. are at ground potential.

Maximum amount of splices for any length of cable

is 3, including the robot plate and transceiver card.

The speed detection signal may be affected if

splices are exceeded. Length in any combination

for the fiber optic is 100-feet.

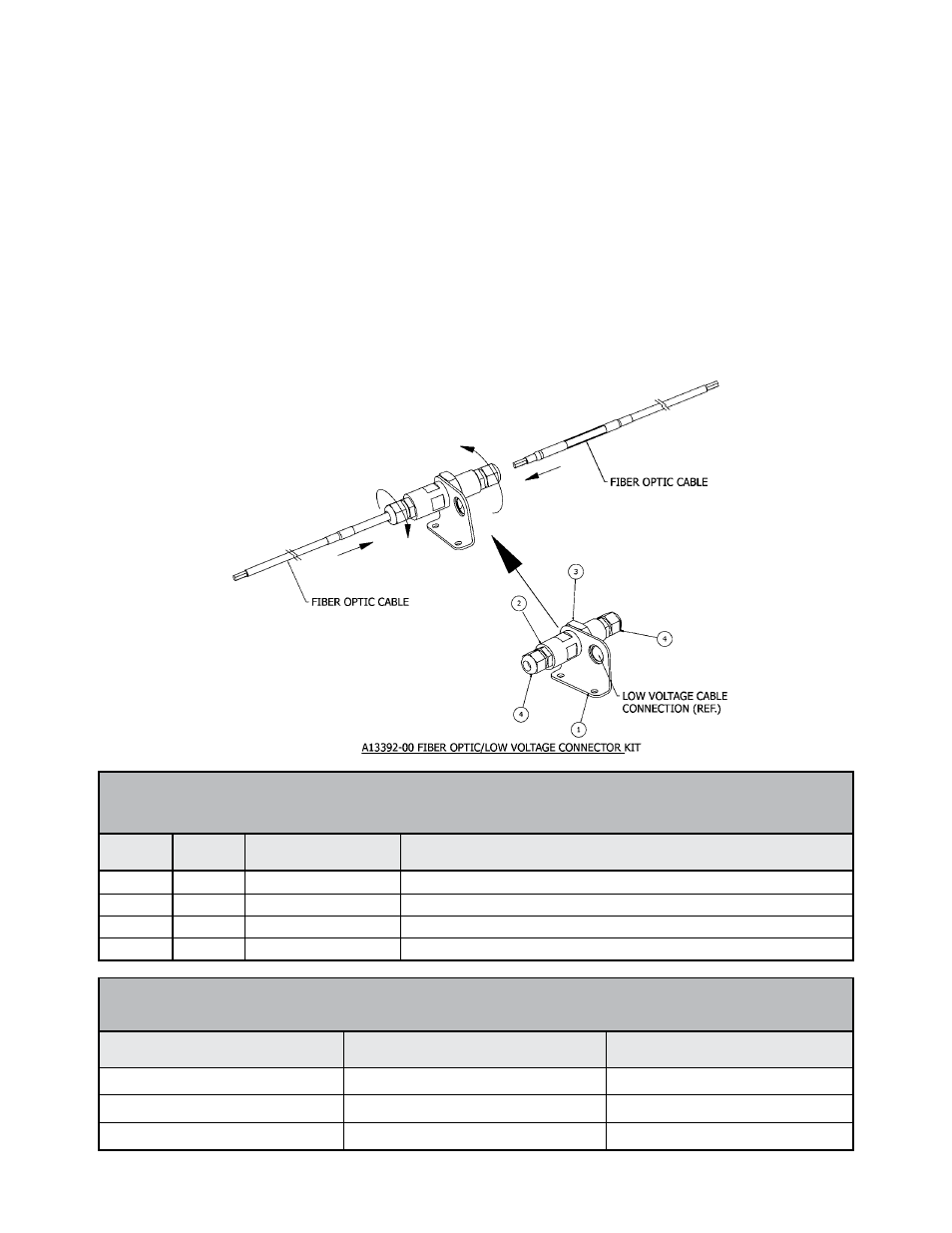

A fiber optic splice connector is available to connect

2 fiber optic cables together. A bulkhead bracket

A13393-00 is available for mounting in the robot

arm along with the low voltage connector.

1

1

A13393-00

BRACKET, FIBER OPTIC/LOW VOLTAGE

2

1

A13391-00

FIBER OPTIC BULKHEAD CONNECTOR

3

1

A13537-00

HEX NUT, M22 X 1.5

4

2

80073-00

STRAIN RELIEF, CABLE GLAND

A13392-00 FIBER OPTIC/LOW VOLTAGE

CONNECTOR KIT - PARTS LIST

Description

Item

Qty.

Part #

FLUID CONNECTIONS

The paint, solvent, and dump fluid tubing are

connected on the back of the robot plate with

stainless steel fittings and PFA tubing. Fluid

tubing requirements are shown in “Fluid Tubing

Connection Requirements” below

.

TYPICAL INSTALLATION

The “Typical Installation of RMA-560” figure in the

“Installation” section shows a typical installation

of the RMA-560 and the wiring installation of the

applicator with the MicroPak.

RMA-560 Single/Dual Purge Direct Charge - Installation

Ransburg

LN-9278-13

29