General description, Ransburg – Ransburg RMA-560 Single_Dual Purge Direct A13364 User Manual

Page 10

GENERAL DESCRIPTION

Bell Cup Assembly

Bell cups are made of high strength Titanium, Alu-

minum or High Wear Coated Aluminum. Serrated

cups are available in 30mm, 55mm and 65 mm.

Non-serrated are available in 55mm and 65mm.

See ordering matrix for exact size and material

combination availability.

Air Bearing Turbine Assembly

The air bearing turbine assembly with bell cup

is mounted to the air manifold assembly with a

turbine retaining ring.

Air Manifold Assembly

The atomizer extension is angled at 60˚ for robot

applications. The fluid feed tube and fiber optic

turbine speed emitter are threaded into the front of

the manifold. The turbine, fluid, and air manifolds

are separated from the bell plate assembly by five

support rods. Nested between the manifolds and

the bell plate is the high voltage cascade.

Bell Plate Assembly

The bell plate assembly is designed to be at

ground potential when mounted to the robot plate

component within the tubing bundle assembly.

The air and fluid ports are compactly oriented for

use in robotic applications. The air supplies are

ported through the five support rods directly to

the air manifold assembly. On the exterior side of

the bell plate, the ports are provided with O-ring

seals so that the atomizer can be quickly mated

and secured to the robot plate.

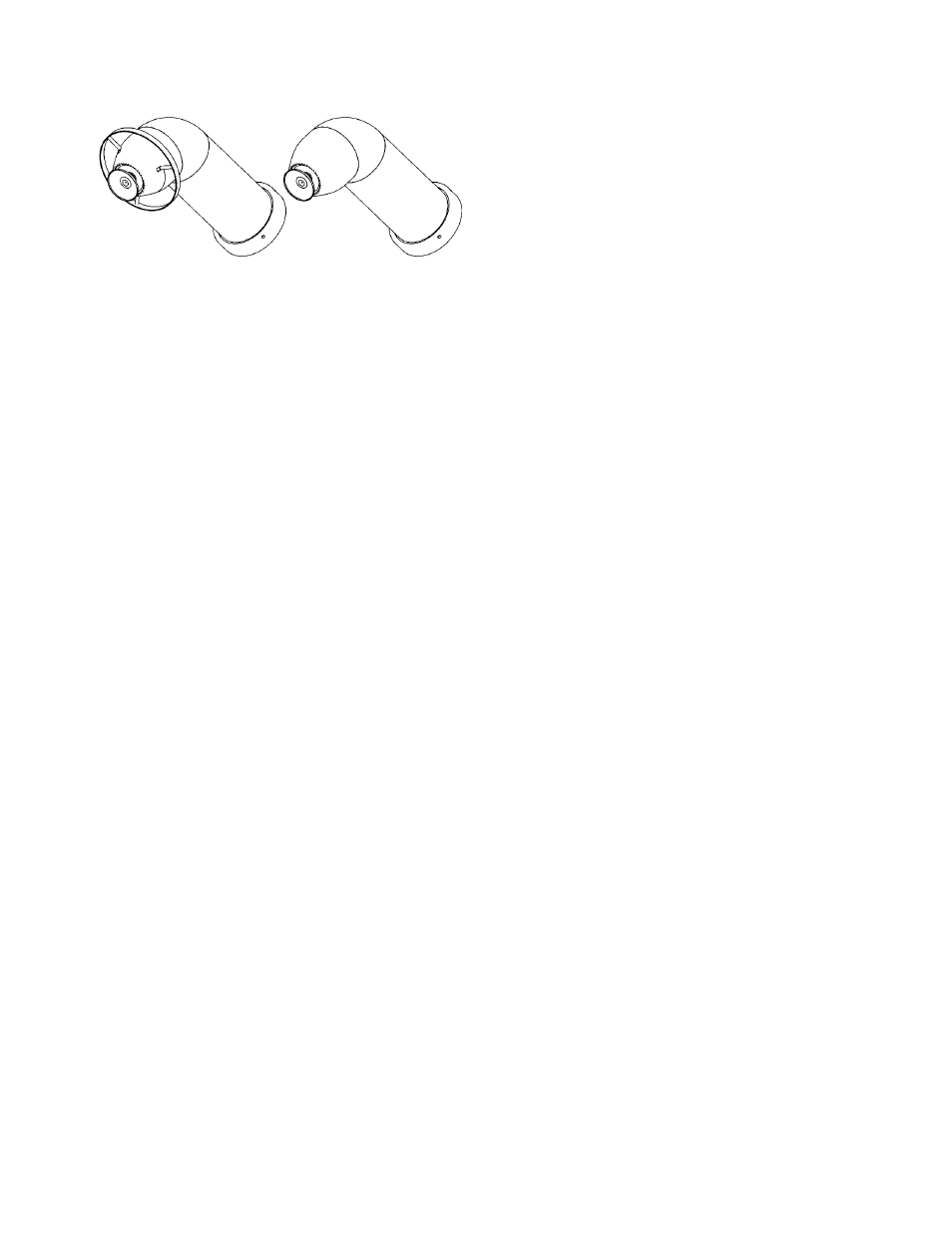

Figure 1: RMA-560 Dual Purge Robot Mounted Rota-

ry Atomizer– Direct Charge. With and without Repul-

sion Ring.

Robot Plate

The robot plate is a component of the tubing bundle

assembly and intended to be permanently mounted

to the robot. A wrist adapter is also available, which

matches the robot’s mounting configuration. The

incoming air lines, fluid lines, low voltage cable,

and fiber optic cable are connected to the fittings

provided at the robot plate. The bell plate of the

atomizer assembly is secured to the robot plate

with a threaded retaining ring.

Valve Manifold

This manifold can be configured for either single or

dual purge application. The dual purge can allow

two colors to be loaded at one time.

Break-Away Feature (Optional)

The RMA-560 is available with or without a break-

away feature. By replacing the five (5) stainless

steel screws with five (5) special designed plastic

screws (77524-00). This feature minimizes the

damage to the atomizer or robot, if a collision

occurs, the five (5) plastic break-away screws fail

and the atomizer will break free. This will leave the

break-away ring and the mounting ring attached

to the robot. (The applicator will fall to the booth

grate or floor).

Power Supply and Controls

The high voltage cascade is located inside the

applicator and is controlled by the MicroPak con-

trol unit. The low voltage output of the MicroPak

is multiplied by the internal cascade to the high

voltage level required. This eliminates the need

for a high voltage cable. A low voltage cable inter-

connects the cascade and MicroPak control. The

MicroPak format is designed to fit in a conventional

19-inch or 10-inch rack and requires a 24V power

input at a maximum 3 amps. The MicroPak and

the internal cascade will produce voltages up to

100,000 VDC.

The MicroPak is designed to electronically limit

current to provide safe operation in a spray booth.

The voltage and current draw of the atomizer are

continuously displayed on the MicroPak control

panel. Voltage and over-current limits are ad-

justable on the front of the MicroPak. MicroPak

RMA-560 Single/Dual Purge Direct Charge - Introduction

Ransburg

LN-9278-13

7