Cleaning shaping air holes, Ransburg – Ransburg RMA-560 Single_Dual Purge Direct A13364 User Manual

Page 52

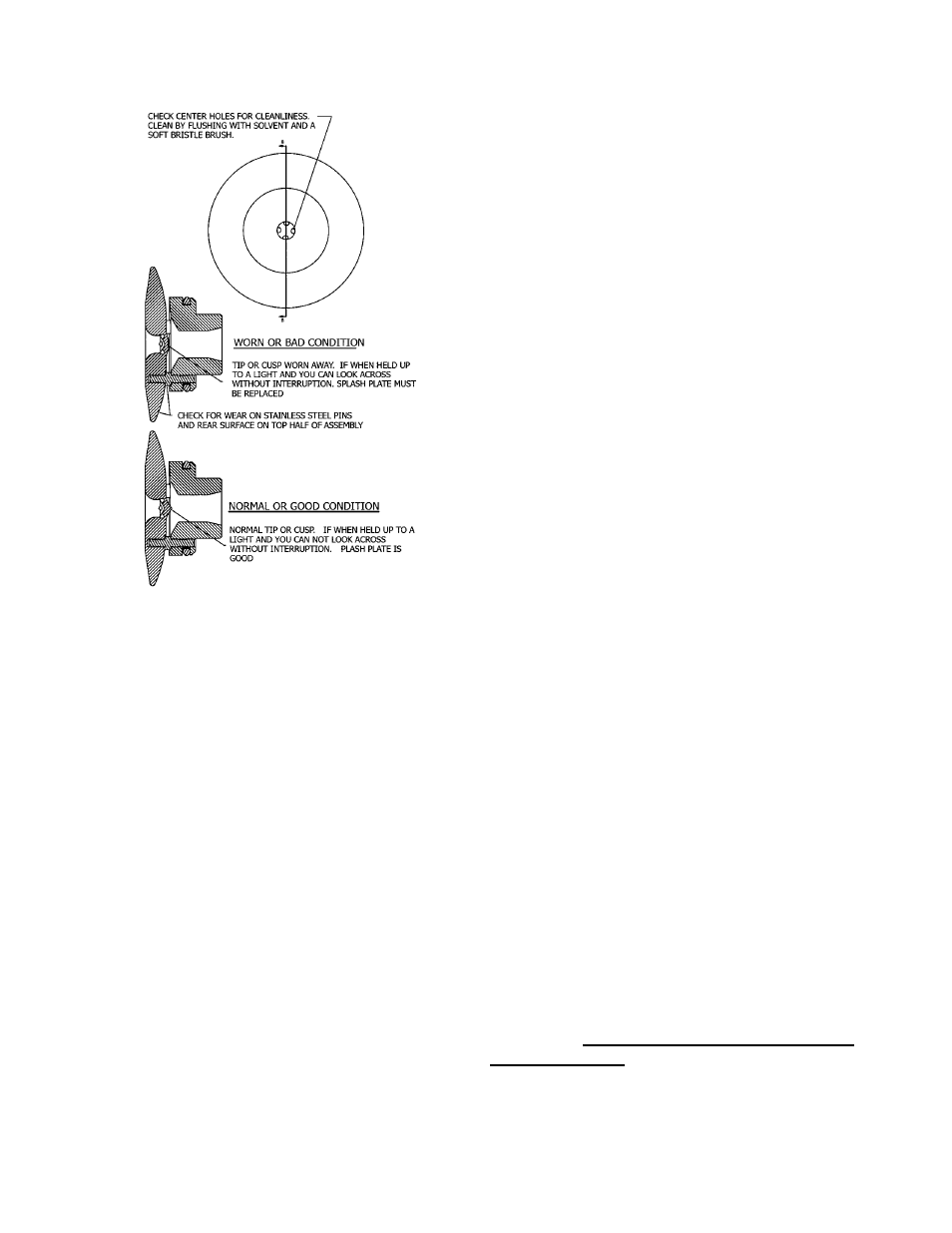

Also, check the three (3) pins between the

front and rear splash plate halves. If worn,

replace entire assembly.

6. Check the center holes of the splash plate

for wear. Hold splash plate up to a light

source and look straight into the holes. If

light is clearly seen, the angled holes are

worn and the splash plate must be re-

placed.

7. Splash plate assemblies may be soaked for

a short time, under 2 hours, to loosen dried

material. Clean with a soft bristle brush.

Blow out center holes to dislodge material.

Never use any kind of pick instrument to

clean these holes.

8. Soaking the bell in solvent may aid in loos-

ening or removing paint build-up. It is

recommended that the splash plate be re-

moved and cleaned separately.

9. Use a soft bristle brush dipped in solvent

to remove paint build-up from the serration

cuts, paint feed holes or slots, and exter-

nal and internal surfaces of the bell.

Inspection of Bell Cups

CLEANING SHAPING AIR HOLES

In order to maintain uniform pattern control, the

shaping air holes of the inner ring and the shaping

air cap must be clean and free of any blockage.

It is best to leave the shaping air supply ON

during normal production break cleaning periods.

Shaping air can be reduced to 70 slpm during this

time. This will help stop material from entering

the passage ways.

Periodically (weekly) the outer shaping air cap and

the inner shaping air ring should be removed and

thoroughly cleaned. Use of an ultrasonic cleaner

would make cleaning of hole diameters easier.

Inspect all holes for blockage. Blow holes clear

with compressed air after some time of soaking

in solvent.

DO NOT use any type of pick to

clear the holes. Damage may result to parts

and could affect performance of the equipment.

If holes are damaged (oversized holes, blockage,

and gauges) it must be replaced.

10. A soft, lint free rag dampened with solvent

may be used to remove any paint residue

from the external and internal surfaces of

the bell.

11. After removing all paint build-up or residue,

rinse the bell in clean solvent and blow dry.

12. Before reinstalling the bell on the shaft,

check the mating surfaces of the thread

and taper for any paint build-up or residue.

Also, check the fluid tip, fluid tube outside

diameter, and the shaft for any further paint

build-up. These surfaces should be cleaned

before installing the bell.

13. It is recommended that extra bell cups be

purchased. The cups can then be cleaned

off line in an automated cup cleaner.

14. Reinstall cups to proper torque 50-70 lbs•in

(5.65-7.91 Nm).

s

RMA-560 Single/Dual Purge Direct Charge - Maintenance

Ransburg

LN-9278-13

49