Installation, Air filter installation, Ransburg – Ransburg RMA-560 Single_Dual Purge Direct A13364 User Manual

Page 26

AIR FILTER INSTALLATION

(GENERAL GUIDELINES)

The following air filter installation guidelines are

essential for optimum performance:

1. Use 25mm OD (1-Inch OD) minimum inbound

main air line.

2. Use only recommended pre-filters and bearing

air filters as shown in “Air filtration Require-

ments” chart in the ”Installation” section. Ad-

ditional system air filtration (i.e., refrigerated

air dryer) may also be used if desired.

3. Mount all the air filters as close as possible

to the RMA-560 applicator. (DO NOT mount

further than 30-Feet (9.1 meters) away.)

4. DO NOT use tape, pipe dope, or other thread

sealant downstream of the bearing air filter.

Loose flakes of tape or other sealant can break

loose and plug the very fine air holes in the

turbine air bearings.

5. Air heaters are highly recommended for use in

the system to minimize the effect of excessively

humid conditions and maintain turbine load

capabilities. If the heated air will exceed 120°F

(48.9°C), the heater must be located after all

filters to prevent damage to the filter media.

With the exception of fluid, dump, and bearing

air, all other pilot and air supply lines should be

bulk-headed and their diameters increased one

size. For example: Turbine air should be increased

to 12mm OD from bulkhead plate to the volume

booster or heater outlet.

Volume Booster Recommendation

(Turbine Air): (For use with A11065-05

Air Heater or Non-Air Heater System)

Ransburg Part # A11111-00

•

Pilot Operated Regulator Non-Bleed Pilot

•

SCFM-200

•

Supply - 300 P.S.I.

•

Temperature Range: 40˚ - 120° F

NOTE

Each applicator must have its own filter

for bearing air. Recommended: RPM-418

or equivalent.

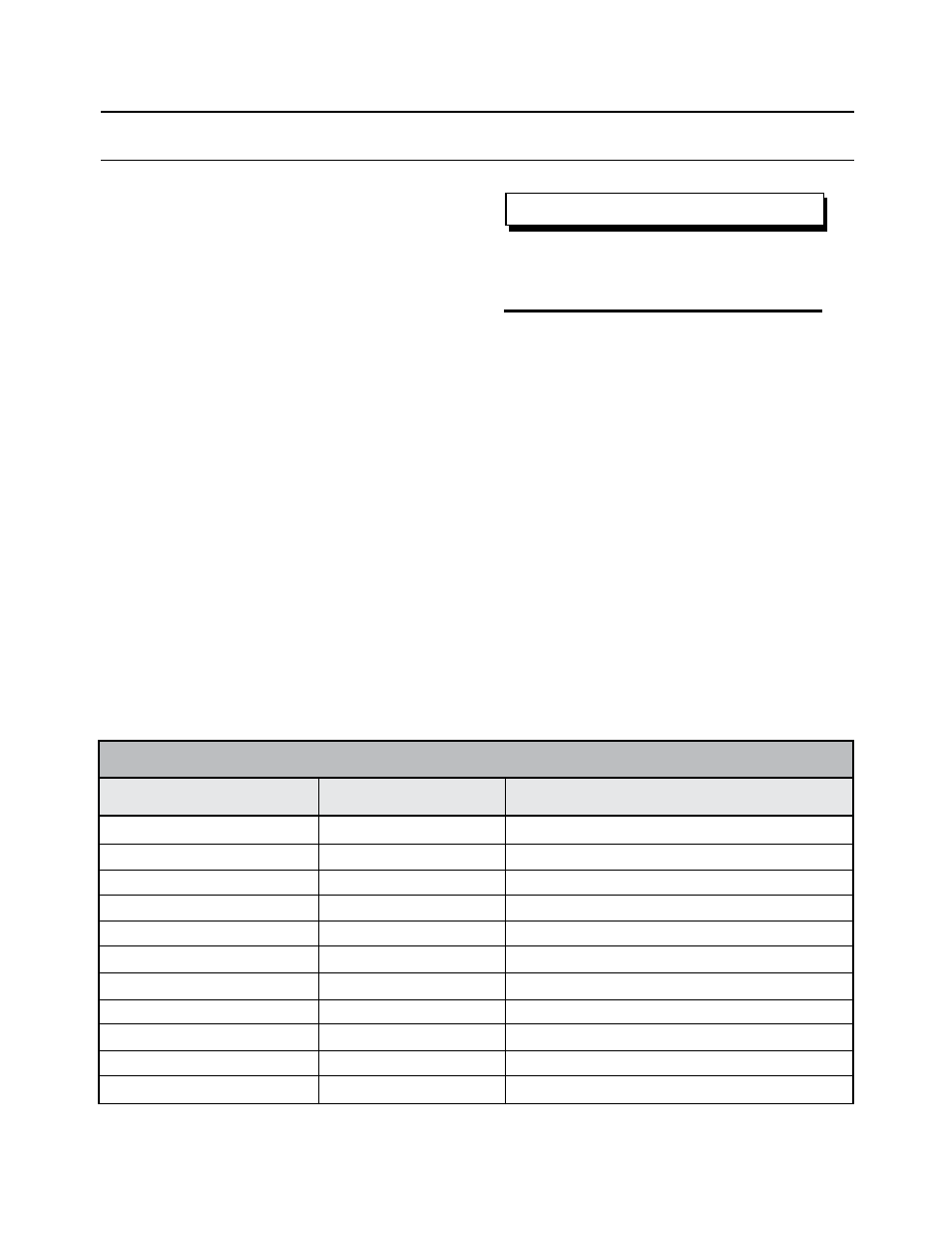

TUBE SIZE AIR PRESSURE REQUIREMENTS

Tube Size

Air Pressure Requirements

Bearing Air Supply (BA/PT)

8 X 6 mm (Natural)

(90 psi +/- 10 kPa) (621 +/- 69 kPa)

Bearing Air Return (BA RTN)

4mm (5/32”) (Yellow)

90 psi +/- 10 at atomizer card (552 +/- 138 kPa)

Turbine Air (T.A.)

10 X 8mm (Green)

Variable

Outer Air (SAO/FA)

8 X 6mm (Gray

Variable

Pattern Control Air #1 (SAI/AA)

8 X 6mm (Blue)

Variable

Brake Air (BRK) (if used)

8 X 6 mm (Natural)

60-100 psi (414-689 kPa)

Paint Valve #1 (P1T)

4mm OD (5/32”) (Natural) 80 psi +/- 10 (552 +/- 70 kPa)

Dump Valve #1 Control (P1D)

4mm OD (5/32”) (Gray)

80 psi +/- 10 (352 +/- 70 kPa)

Solvent Valve Control (ST/RP)

4mm OD (5/32”) (Blue)

80-100 psi (552-873 kPa)

Paint Valve #2 (P2T)

4mm (5/32”) (Natural)

(552 +/- 70 kPa)

Dump Valve #2 Control (P2D)

4mm (5/32”) (Black)

80 psi +/- 70 kPa)

INSTALLATION

RMA-560 Single/Dual Purge Direct Charge - Installation

Ransburg

LN-9278-13

23