Bell cup cleaning, Ransburg, Bell cup handling – Ransburg RMA-560 Single_Dual Purge Direct A13364 User Manual

Page 51: Bell cup replacement

Bell Cup Handling

Always verify that high voltage is turned off and

the atomizer bell has stopped spinning before

performing any type of handling maintenance.

Bell Cup Replacement

Bell cup wear is dependent on many factors such

as bell speed, flow rate, and type of coating being

applied.

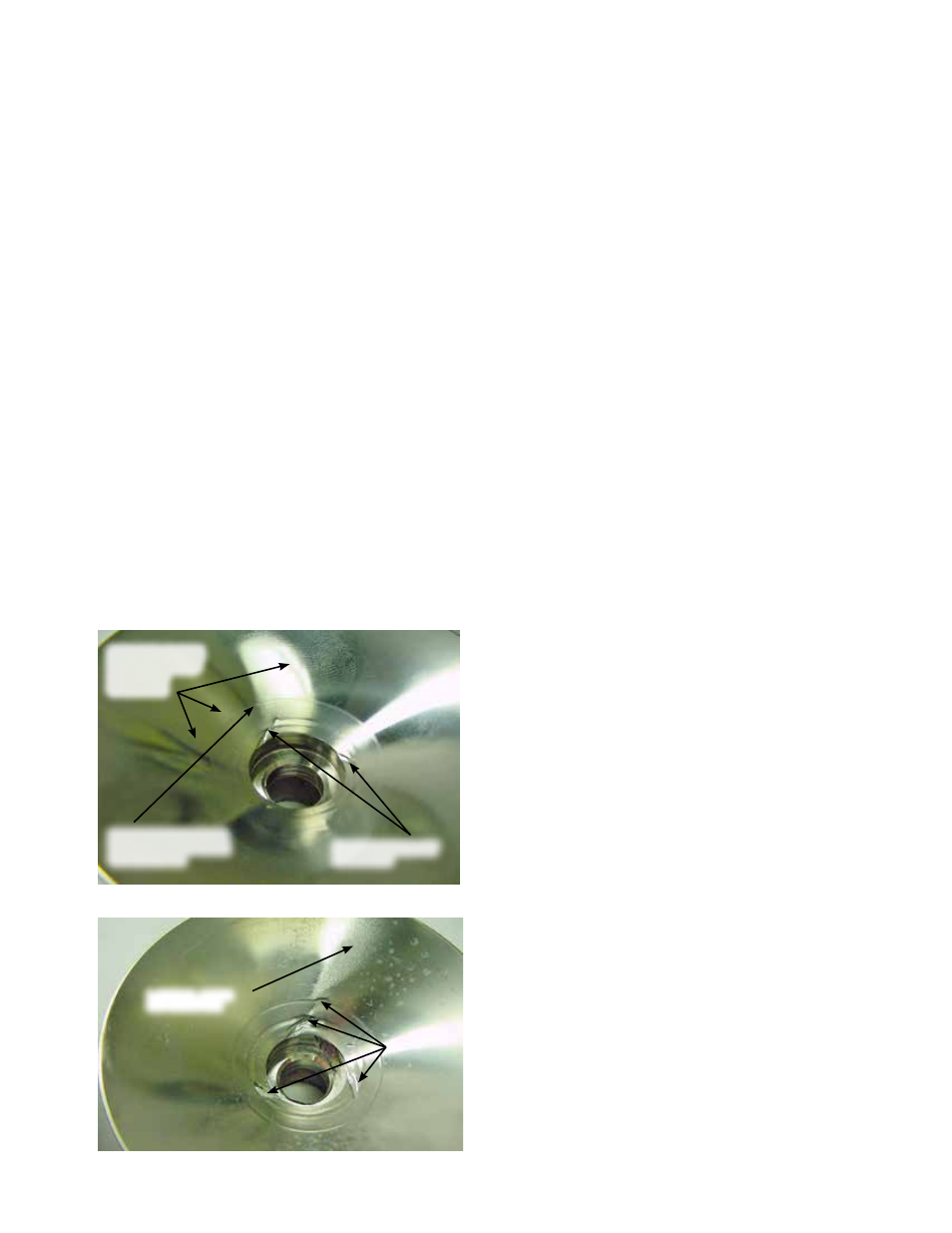

The bell cups shown in the photos below indicate

if a bell cup has some useable life or should be

replaced. Photo 1 shows a bell cup that has some

useable life. The grooves worn around the splash

plate pins are shallow. The general appearance

of the cup surface is smooth and uninterrupted.

Photo 2 shows a bell cup that needs to be replaced,

as well as the splash plate that was installed into

the cup. The grooves are deep, a visible groove

exists at the outer edge diameter of the splash

plate and there are noticeable lateral grooves

extending towards the outer edge of the cup.

Photo 1

Photo 2

LATERAL LINES

OR GROOVES

DEEP

GROOVES

SMOOTH CLEAN

UNINTERUPTED

BELL CUP

SURFACE

LIGHT VISIBLE WEAR

NEAR SPLASH PLATE

OUTER EDGE

SLIGHT, SHALLOW

GROOVES

BELL CUP CLEANING

Always verify that high voltage is OFF and that

the atomizer bell is spinning before performing

any type of color change or bell flush cleaning

cycle.

To reduce the risk of fire or explosion, the sol-

vents used for exterior cleaning must have flash

points above 100°F (37.8°C). Since electrostat-

ic equipment is involved, these solvents should

also be non-polar.

Solvents used for equipment flushing should

have flash points equal to or higher than those

of the coating material being sprayed.

1. The atomizer bell will normally be fully

cleaned during a bell flush cycle. Flushing

should be done before any down time or

break in production. A bell flush cycle may

also be required while spraying batch parts

of the same color. Verify that high voltage is

in off and that the atomizer bell is spinning

before flushing through the bell.

2. If there is any remaining paint build-up on

any areas of the bell after flushing, the bell

cup should be removed for hand cleaning.

The bell’s leading edge, splash plate, serra-

tion cuts, and rear of cup are some exam-

ples of areas for special attention.

Bell Cup Soaking

3. Bell cups and splash plates can be soaked

in a heated solution for up to 2 hours in an

ultrasonic cleaner (120°F. 49°C maximum).

Bell cups alone may be soaked for an ex-

tended amount of time.

Manual Inspection

4. Visually inspect the bell cup edge for signs

of abrasion. If the edge is excessively worn

or badly chipped as the result of a collision

with a part, replace the cup immediately

5. Remove splash plate. Inspect for wear on

the bell cup where the fluid leaves the large

diameter of the splash plate. If any under-

cut in this area, the cup should be replaced.

RMA-560 Single/Dual Purge Direct Charge - Maintenance

Ransburg

LN-9278-13

48