Low voltage cable installation and removal, Ransburg – Ransburg RMA-560 Single_Dual Purge Direct A13364 User Manual

Page 43

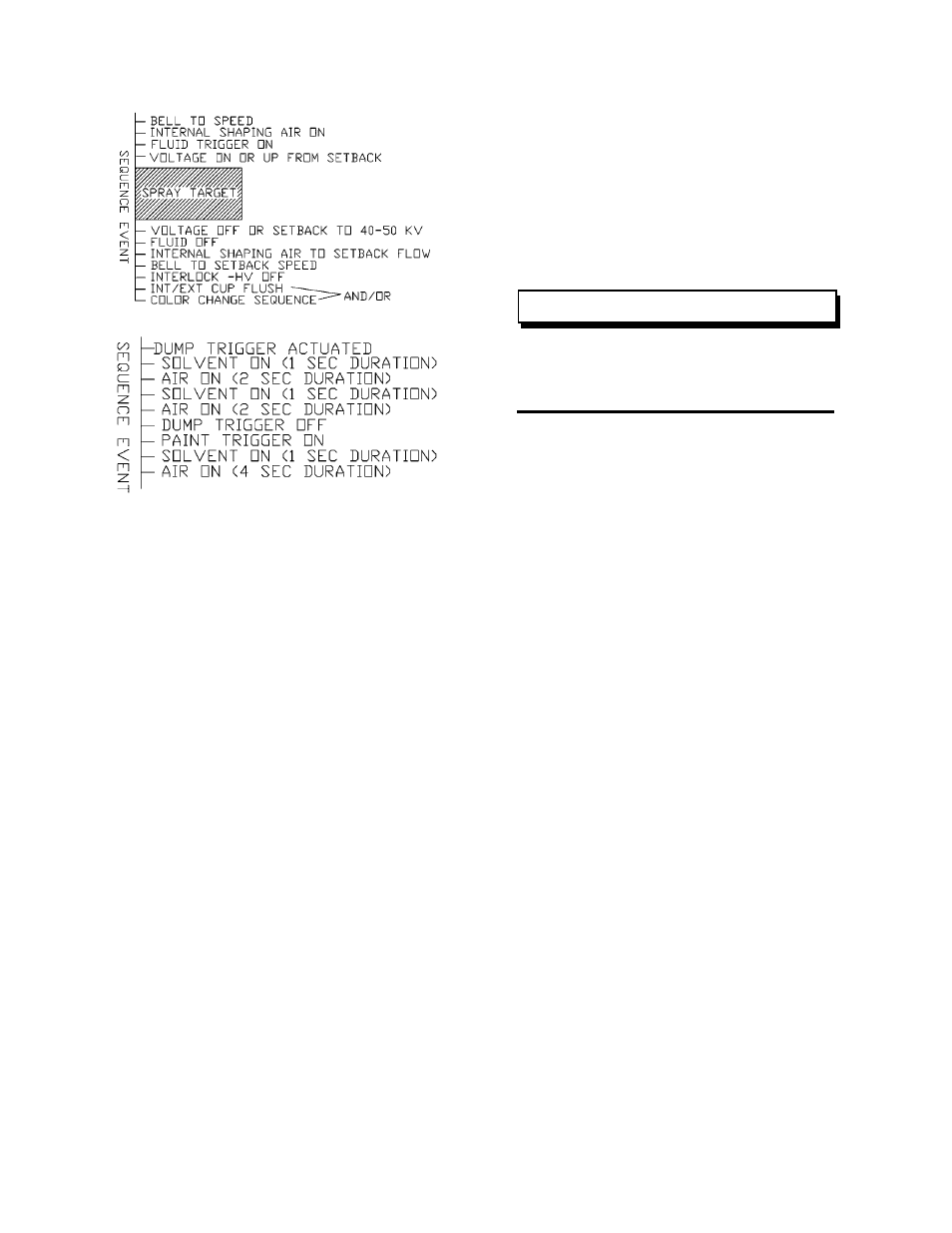

Typical Paint Sequence

Typical Color Change Sequence

Sequence Event Explanation:

1. Bell to Speed - This is accomplished by

a set point command from either the PLC,

robot, or other input device, through the I/O

module.

2. Shaping Air - Set to 350-450 (12.4-15.9

SCFM) while performing a cup flush.

3. Voltage On - The voltage is turned on from

a signal to the MicroPak. The lag time to

full voltage may be reduced if a setback

voltage is used. Recommended setback

voltage is between 30 kV and 50 kV.

4. Trigger Fluid - An air signal is sent through

the PT line of the tubing bundle. This

should occur when the target is 6-12-inch-

es (152.4-304.8mm) from the applicator

centerline. (Not to be confused with target

distance.)

5. Voltage Off/Setback Voltage - Immediately

precedes the trigger off. Using a setback

voltage shortens the cascade voltage ramp

up time.

6. Fluid Trigger Off - This should occur

when the target is typically 0-6-inches (0-

152.4mm) past the applicator centerline.

7. Shaping Air to Setback - The setback flow

of air should never be below 70 slpm (2.6

SCFM) for the shape air.

8. Color Change Sequence - Used when col-

or is changed one to the other. Typical se-

quence is shown in “Typical Color Change

NOTE

During this sequence, the applica-

tor should be moved to a position to

collect the waste material.

Sequence” figure in the “Operation” section.

The sequence shown is a starting point for

processing, but the final sequence will de-

pend on the material being sprayed and the

solvent used to purge the applicator with.

LOW VOLTAGE CABLE

INSTALLATION AND REMOVAL

(See “Quick Disconnect Cables” and “Low

Voltage Cable On Robot” figures)

A low voltage cable is provided to send power to

the high voltage cascade in the atomizer as well

as sending important information during operation

back to the MicroPak controls. One piece of the

cable is a permanent length of approximately

60-inches (1.5 meters) from the robot plate end.

The connecting Cable can be ordered in various

lengths depending on the distance required to

reach from the robot arm to the MicroPak controller.

The ends of the cables have a male and female

quick disconnect end. This provides for a quick

and easy removal of the cable at the robot plate

if servicing or replacement is required.

It is important the quick disconnect fitting be se-

cured to a good ground source. The A12241-XX or

A12493-XX cable is supplied with a ground cable

which can be secured to the bulkhead connector

and the other end to a known ground source.

The cable can also be grounded by attaching the

bulkhead connector to a grounded bulkhead plate.

The bulkhead plate can be nor more than 1/8-inch

RMA-560 Single/Dual Purge Direct Charge - Operation

Ransburg

LN-9278-13

40