Magnum Venus Plastech Flex Molding Process MKVI Mix User Manual

Page 66

MKVI Mix Meter System Operations Manual

Rev. 08/2013

Page | 66

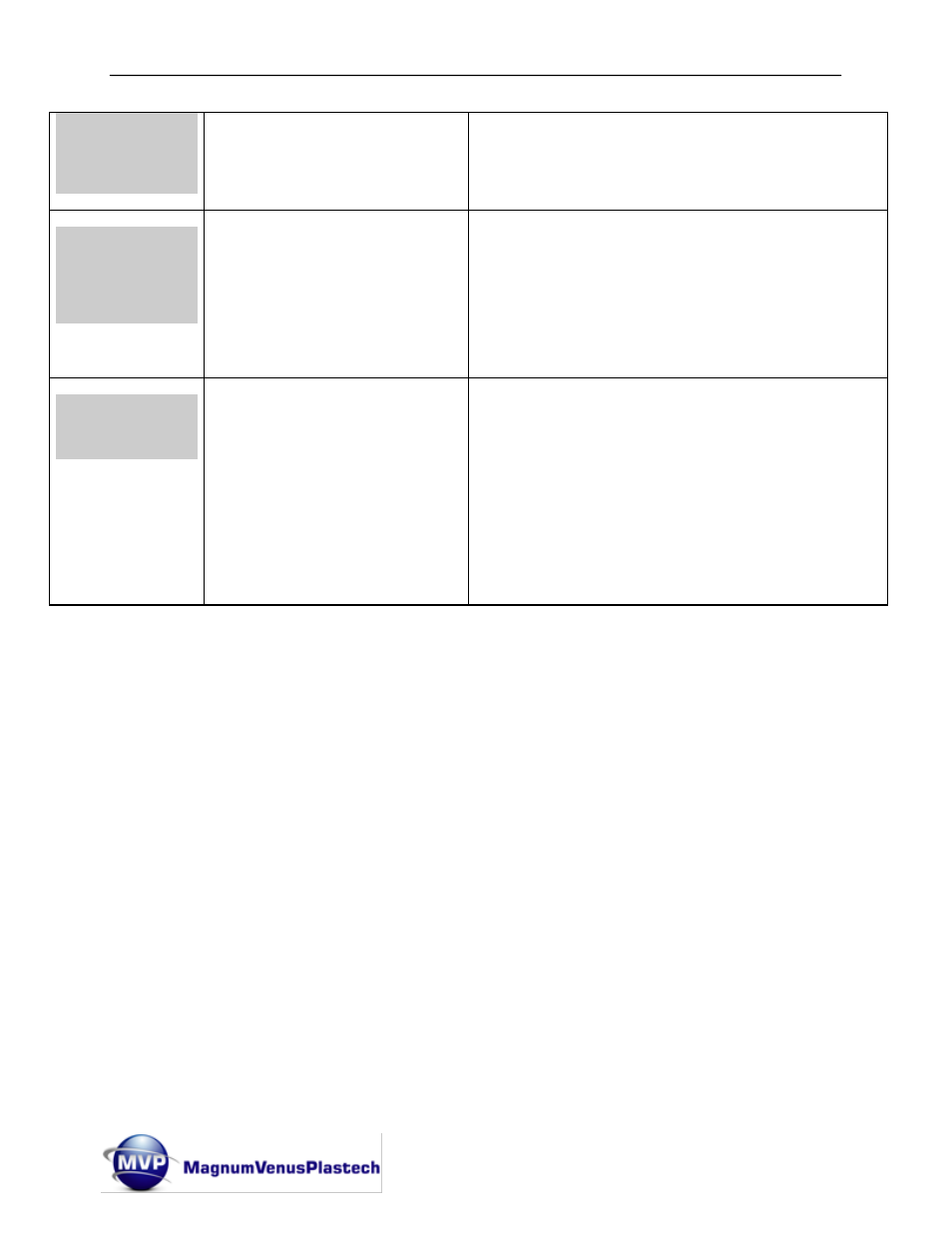

E:

CATALYST FAILS

TO PUMP ON BOTH

PUMP STROKES

WHEN RECYCLED

1. AS 1, 2 & 3 ABOVE

2. CATALYST PICK-UP FILTER

CLOGGED

As above

It is imperative that this submerged filter remains clean. Remove from

pipe end, flush in water and air purge to dry.

F:

AIR BUBBLES

OBSERVED IN

CATALYST

RECIRCULATION

FLOW

1. CATALYST LEVEL LOW

2. CATALYST LOWER PUMP INLET

PIPE CONNECTION LOOSE

3. CATALYST LOWER BODY SEAL

WORN

4. CATALYST CONTAMINATED

Refill Catalyst bottle

Check fitting for tightness. If metal olive seal is damaged then renew.

Renew ‘O’ ring seal.

Safely discard contaminated Catalyst. Clean entire catalyst fluid section

and refill with fresh catalyst.

G:

‘WET’ MOULDING.

UNCATALYSED

RESIN PATCHES

1. PUMP REQUIRES REPRIMING

2. WORN SEAL OR RESIDUE IN

EXTERNAL NRV AT HEAD

3. NRV8 SEAL FAILURE

4. AIR/GAS BUBBLES IN

CATALYST

5. SOLVENT LEAKING INTO MOULD

WHEN INJECTING UNDER

VACUUM

Check sufficient Catalyst level. Re-prime Catalyst pump

Service Head external NRV

Service NRV8. Ensure good seal between PTFE cone and seat

Check 1, 2 & 3 above.

Service solvent isolation valve mounted on machine frame, replace seals

if required.