Catalyst auto valve assembly – cav – Magnum Venus Plastech Flex Molding Process MKVI Mix User Manual

Page 49

MKVI Mix Meter System Operations Manual

Rev. 08/2013

Page | 49

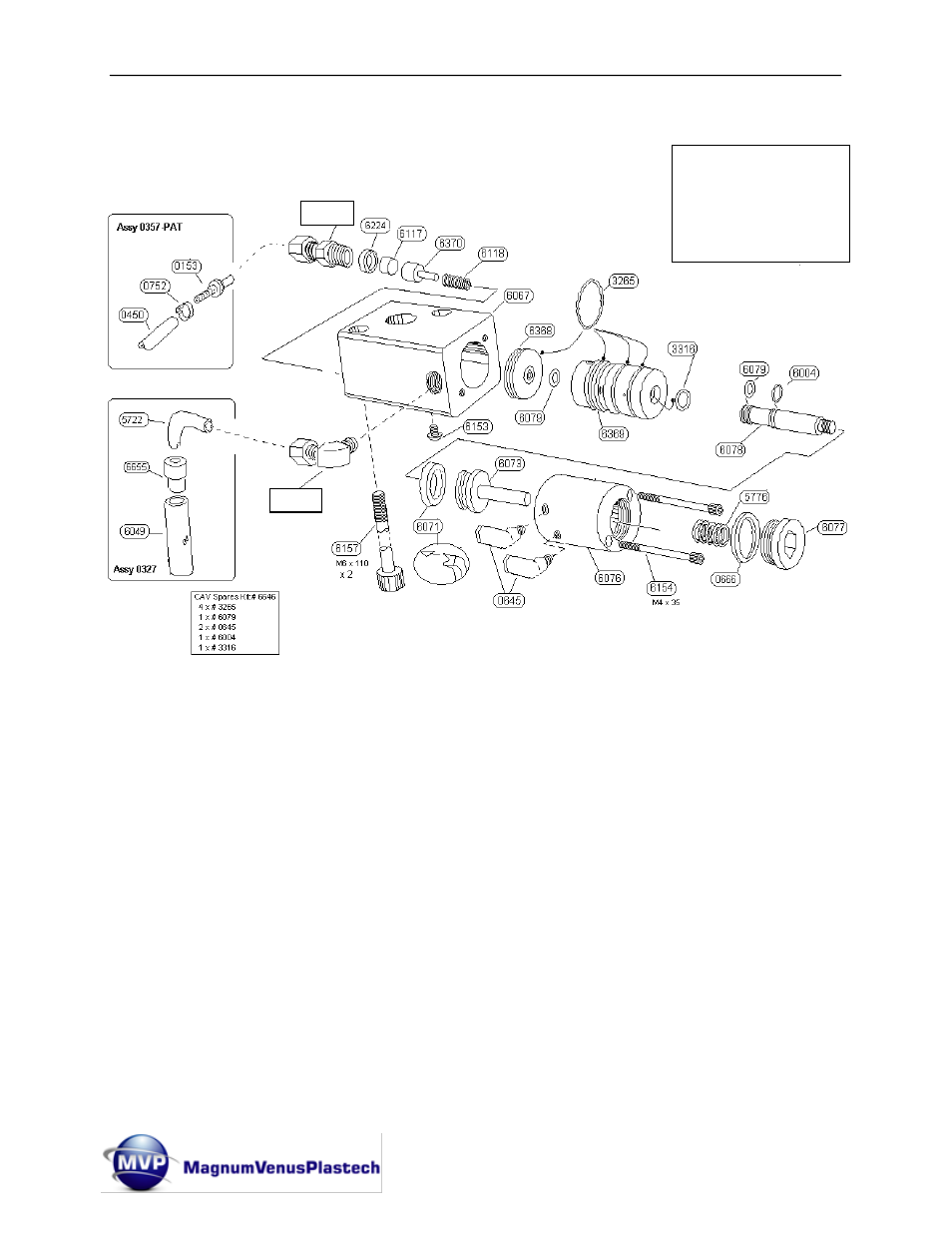

Catalyst Auto Valve Assembly

– CAV:

CAV Servicing notes:

The catalyst auto valve needs little servicing as all components are suitable for both

MEKP and recommended AAP catalysts

The movement of the spool as indicated from the aluminum air cylinder end should be

between 4 and 5 mm. Any less or greater can cause Catalyst to flow incorrectly so

ensure this movement is observed to be correct by measurement using calipers after

service and before using the machine in production.

Take care not to damage or scratch the Spool Internal Body (6369) when O-ring (3316)

needs replacing.

The valve should only need servicing if air or catalyst is noted to weep from between the

Air Cylinder (6078) and Stainless Steel Body (6067). In this case the O-ring (3316)

should be renewed.

If catalyst appears to weep back to the catalyst bottle during injection mode then the

internal Spool O-rings (6004) need replacing.

If catalyst is observed to weep from the Injection Nozzle during recirculation mode then

the small front O-ring (6079) needs replacing.

Assy-0425 CAV Assembly

See drawing 83018_XX for

correct part numbers.

6150

6150