Magnum Venus Plastech Flex Molding Process MKVI Mix User Manual

Page 30

MKVI Mix Meter System Operations Manual

Rev. 08/2013

Page | 30

Changing between Ratios & Materials:

1. Properly flush and clean the fixed 100cc Fluid Section of the existing material. Using

solvent purge the fixed 100cc fluid section and hoses of the material being removed.

Purge the Solvent from the system (pump and hoses) and clean or replace any

items that will contaminate the new material.

2. Secondary Pump - If the system is using the 20cc, 50cc or another 100cc fluid

section to meter the second material (hardener, activator or B-component) also flush

and clean this pump. As with the main component material purge the secondary

pump and hose with solvent or cleaning agent.

3. When using the Catalyst Pump (5cc pump) with MEKP catalyst it will not necessary

to purge out the catalyst unless the catalyst and pump will not be used for more than

six months. If the catalyst system will sit idle for longer than the expiration date of

the catalyst than drain and pump out the catalyst system. Clean the catalyst jug and

feed tube with warm water, remove and clean any filters.

4. Disconnect and remove the Secondary pump and replace with the new fluid section.

Set the new pump at the desired ratio on the Ratio Arms and connect to the injection

head using the correct hoses.

5. If necessary reconnect the Interlock Air Signals from the Hardener RAV (1:1) to the

Catalyst CAV (188:1) or the other way around.

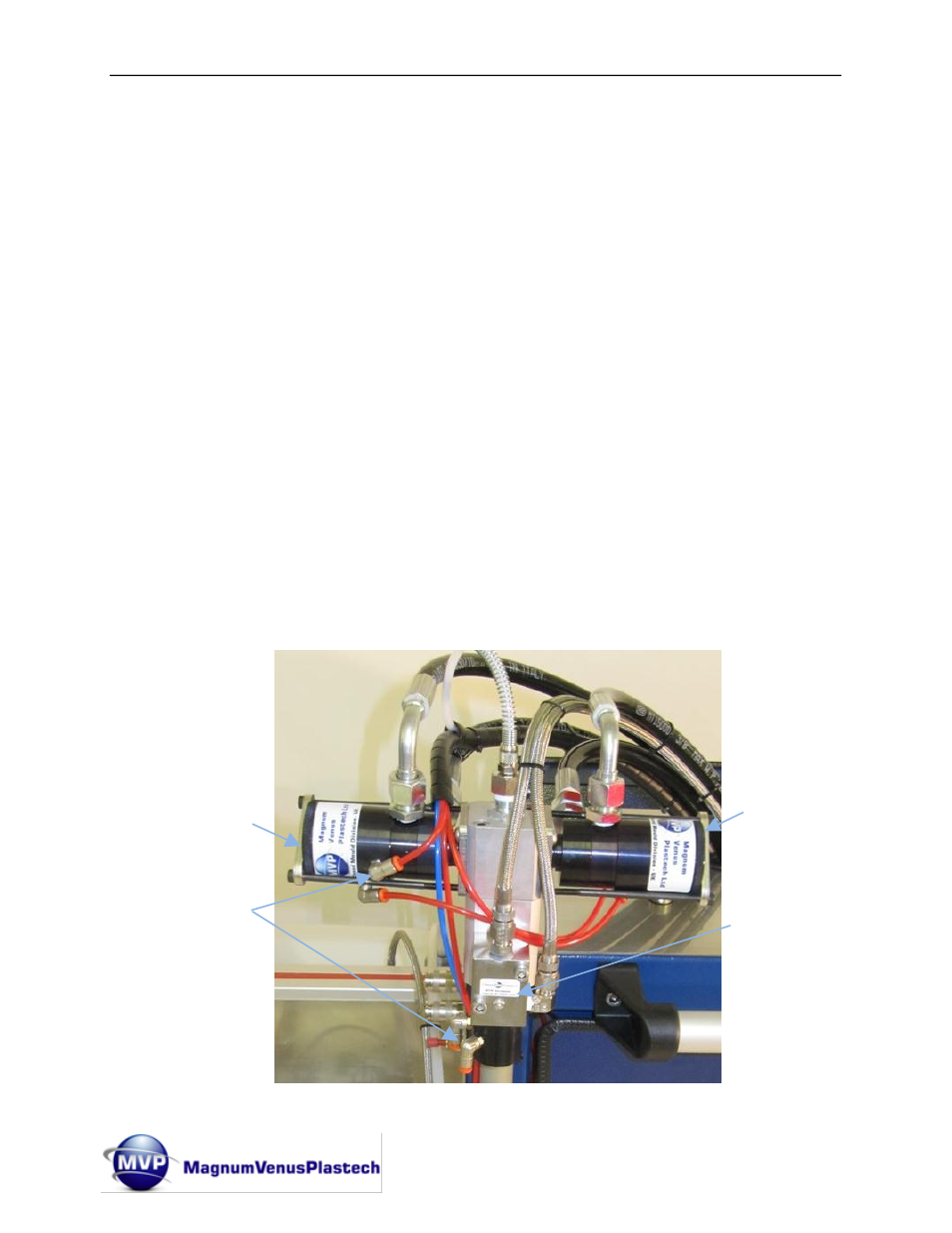

Megaject Auto Head

– 1:1 Configuration with optional CAV

Start / Air Interlock Signals

configured for Dual RAV -

1:1 materials. When

configured for CAV (lower

ratio materials) this will

connect to the CAV signal

ports.

RAV (Resin Auto Valve)

RAV (Resin Auto Valve)

CAV (Catalyst Auto Valve)