Mould pressure guard (mpg) – Magnum Venus Plastech Flex Molding Process MKVI Mix User Manual

Page 55

MKVI Mix Meter System Operations Manual

Rev. 08/2013

Page | 55

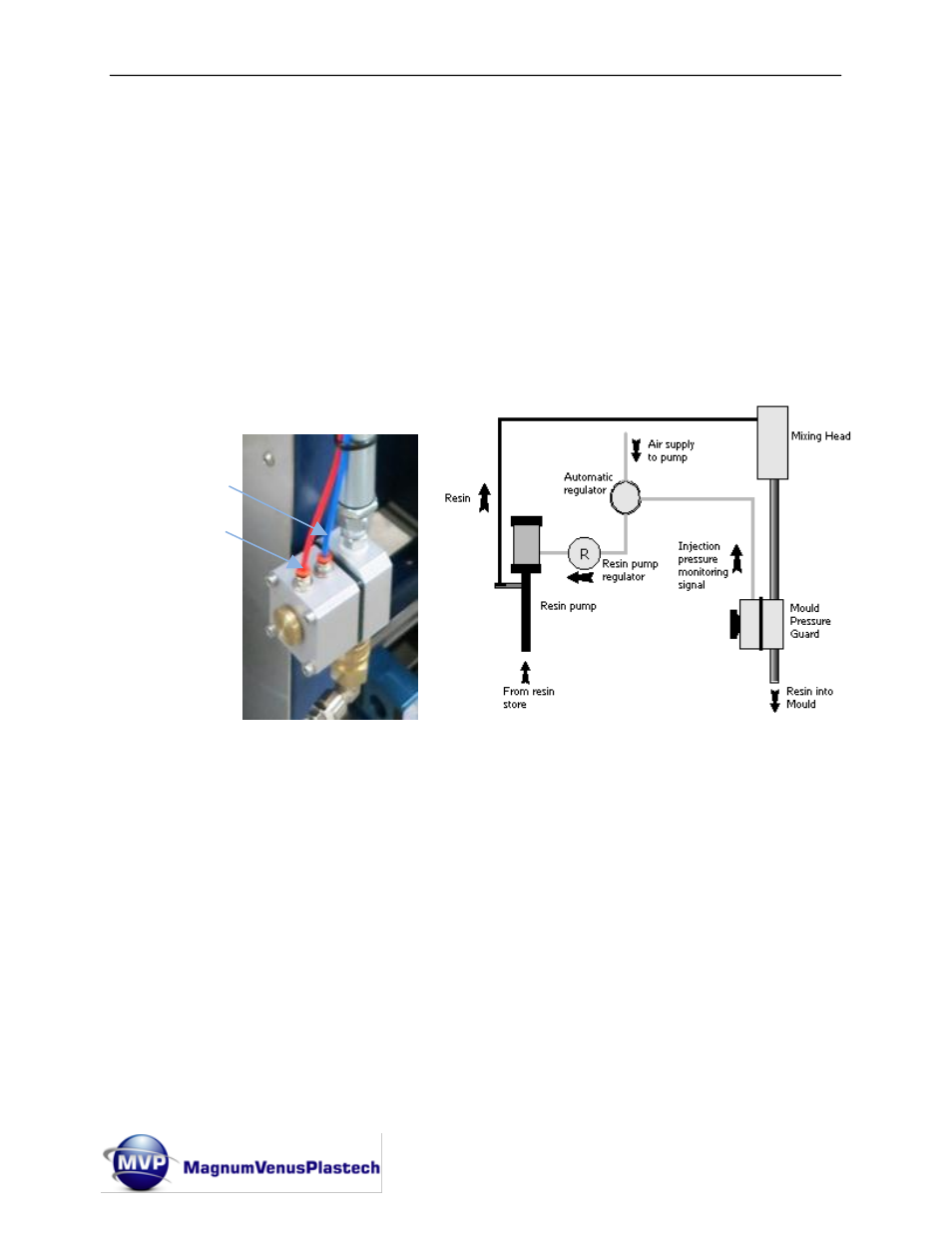

Mould Pressure Guard (MPG):

The machine features a Mould Pressure Guard (MPG), which is used to control the

maximum allowable pressure at the mixing head. This can be utilized to provide line

pressure control during an injection, or as a safety mechanism to prevent the line pressure

from exceeding the maximum working pressure of the injection line to the mould.

The MPG block is shown below. The blue air-line supplies air from the MPG pressure

regulator on the control panel. When fluid pressure at the injection head exceeds the

MPG preset level, shown on the MPG pressure gauge, the internal diaphragm moves

and leaks air from the red air line connected to the control circuit. This causes the

machine to slow and stop.

MPG Operation:

1. Set the maximum injection pressure on the MPG preset level gauge using the MPG

regulator. (Suggested initial setting

– 2 bar)

2. If the resin pressure is below the preset pressure, then the automatic regulator will

remain fully open allowing full main pressure to the resin pump regulator.

3.

If the resin pressure exceeds the preset level, the ‘MPG signal pressure’ will reduce

proportionally closing the automatic regulator and limit air pressure to the resin pump

regulator. This slows or stops the resin pump, reducing resin pressure until it

matches the preset level. During operation, a small leak of air will occur from the

MPG sensor block. This is normal.

4. The MPG preset level may be adjusted during an injection to achieve optimum pump

output speed at the safest injection pressure.

5. Several factors will affect the optimum setting of the MPG regulator, e.g. fiber volume

fraction, mould size and rigidity, resin viscosity, required resin delivery rate etc.

Blue Air Line

– MPG

set pressure

Red Air Line

– MPG

leak signal