4 delivery variables – Liquid Controls Sponsler T675 - Cryogenic System Register User Manual

Page 39

Sponsler, Inc.

Model T675 Flow Totalizer

Technical Information

Pg. 36

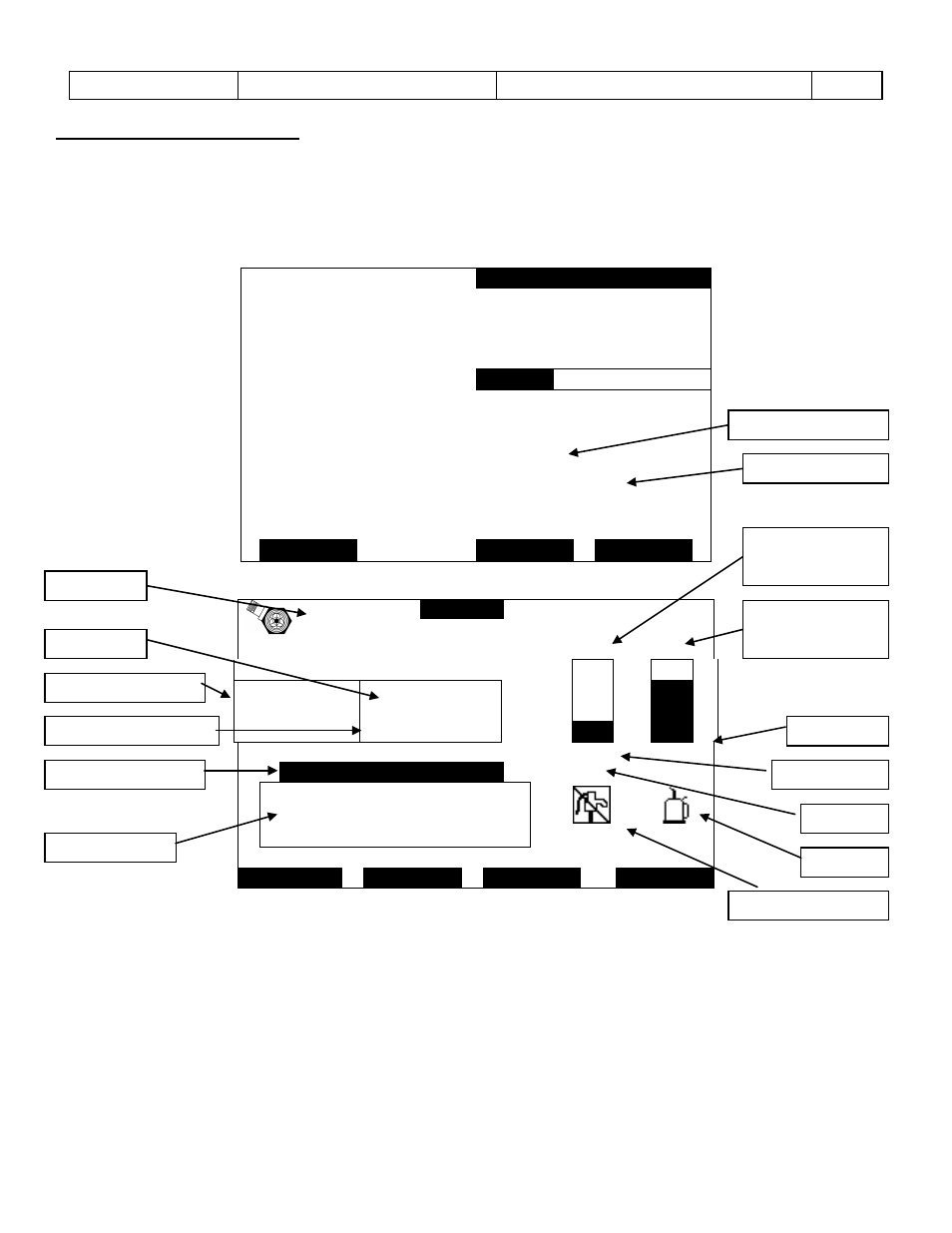

4.4 DELIVERY VARIABLES:

All process variables are real time therefore, the delivery total is displayed in real time, no waiting for an updated total. The

Operating screen displays 9 delivery variables and the Detail screen displays 8 additional. Remember, to access the

Detail screen depress and hold the Detail softkey. Releasing this softkey returns the display to the Operating screen in 5

seconds while depressing the OK softkey immediately returns to the Operating screen.

Detail Screen

INPUT VOLT: 13.7

DELIV PRODUCT:LIN

LAST BATTv: 9.5

P.COIL OHM: 1418.6 TEMP. -195.6oC

LCD HEATER: OFF LOW NBP HIGH

-198 -196 -178

INPUT FREQ: 496.0

CALC KFACT: 148.85

RTD OHMS: 220.8

T/C FACTOR: 1 ADJ: ON

kg/Ltr : .71717 C2 OHM: OFF

Print baud: 9600

Printr Rdy:

* HOLD*

BatTest

* OK *

Operating Screen

29-NOV-07

*T675*

TEMP

RATE

13:44

Ltr/

oC

min

TOTALIZER

AVG K-FACT

000087462 148.9

PPG

10-MAR-06

-195.6

200

Litre

LIN

9407.4

00:15

PMreq

*DETAIL

*RESET*

*PRINT*

*ALARM*

Only when the delivery is completed, a no flow condition, is delivery information available via the I.R. port or RS232

connector to print a ticket. Depress the Print softkey.

Date/Time

Kfactor

Accumulated Total

Engineering Units

Delivery Total

Flowrate

Temperature

Product

Pump Cutout Timer

Alarms

Rate

Engineering Units

Temperature

Engineering Units

Last Kfactor change

T675-PEM Status

Coil 2 resistance