Controlled Products Systems Group HRG 220-A ST User Manual

Page 71

Installation and Maintenance Manual

57

Important aspects to consider when you are replacing

bearings:

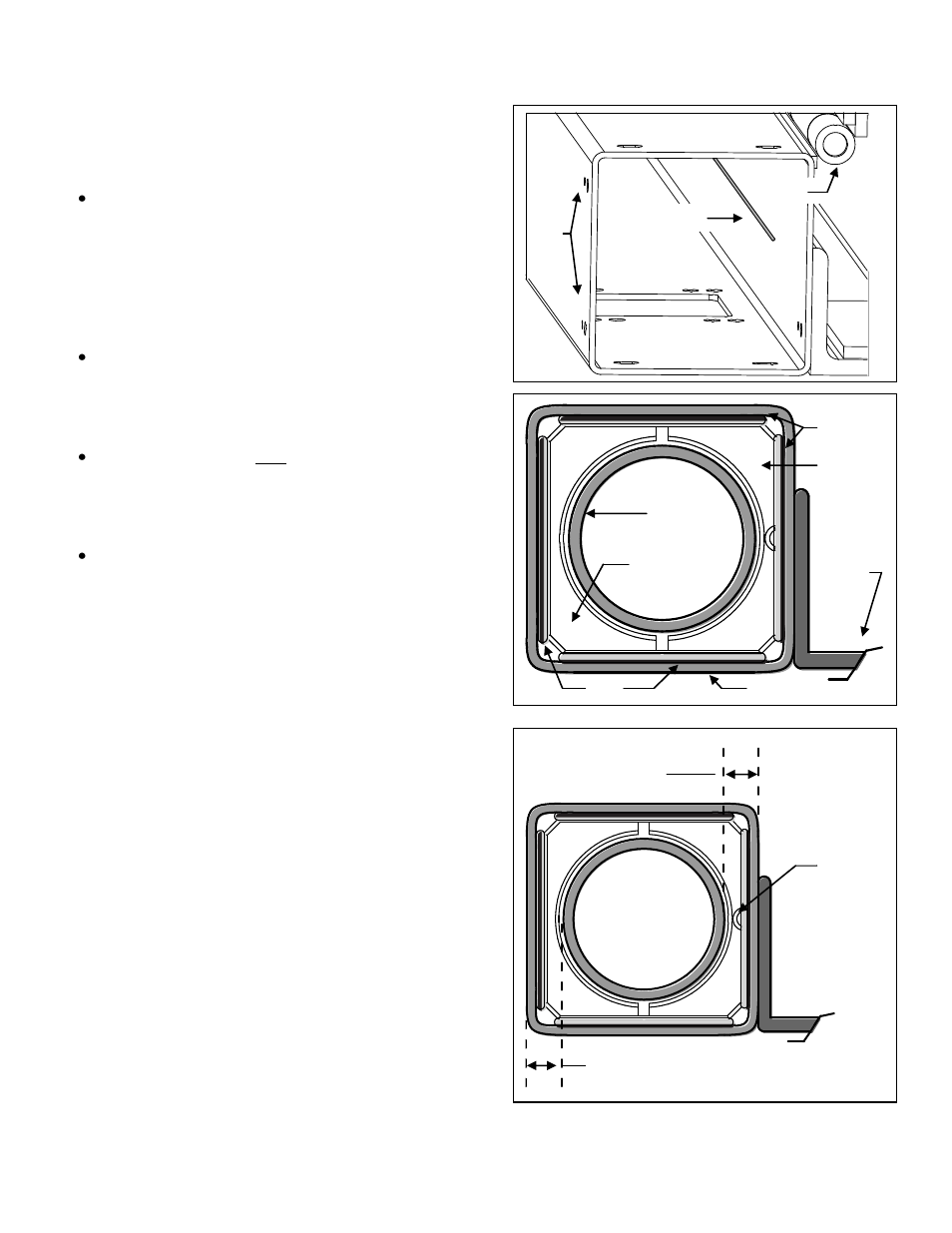

Locate the weld seam inside the square post. It

should run along the side that is attached to the

gate hinges. The notched portion of the bearing

half must be installed so that the notch aligns

with the weld seam. If the weld seam is not

evident inside the post, place the bearing so the

notch is on the hinge side.

Shims are inserted at the factory with 0.0 to

0.020-inch clearance in relation to the post.

Replacement bearings need to be shimmed to a

similar clearance.

When installing new bearings, use an equal

number of shim packets on opposite sides. The

packets may be composed of 0.060 and 0.020

shims.

Always start with a .060‖ shim on each of the

four outside edges when installing a new

rectangular bearing.

To replace the bearings, take the following steps:

NOTE: Refer to SwingRiser Bearings Chart to

determine what replacement kit you need to order.

1. To access the upper bearing, close the gate.

2.

Turn off the gate operator’s power source. This

ensures that the gate will not move while you

are installing the bearings.

3. Use a jack screw to lift and block the gate

panel. This transfers the weight off the

bearings.

4. Loosen the post screws and remove any shims

surrounding the bearings.

¾" (19mm)

Weld

seam

location

Shims

Bearing

half

Hinge

Inner tube

Bearing half

Shim

Post

Weld seam

¼ -20

cap

screw

holes

Hinge

¾" (19mm)