General maintenance – Controlled Products Systems Group HRG 220-A ST User Manual

Page 68

Installation and Maintenance Manual

54

General Maintenance

The reliable design of the SwingRiser Operator significantly lowers ongoing maintenance issues.

However, certain aspects of the operator and gate need to be inspected on a regular basis. These

aspects are addressed in this section and include:

the operator post

the hydraulic system

the electrical controls

NOTE: No lubrication is needed for any part of the operator, including the cam followers in the center of

the operator. A lubrication process applied at the factory suffices for the life of the cam followers.

Operator Post

The operator post is the workhorse of the gate. Schedule regular maintenance on the operator post to

include the following:

Smooth gate operation: Open and close the gate several times. Check for consistent speed and

smooth stops. If adjustment is necessary, refer to Adjustment of the Flow Control Regulating Valve.

Indexing arm: To hold the gate in the correct position, the indexing arm may need to be adjusted to

align the locking pin with its receptacle. Adjustment is usually required only after the gate has been hit by

a vehicle or otherwise damaged.

To adjust refer to Mounting the Gate Panel, Index Arm, and Locking Pin Assembly.

The most reliable operation occurs when the indexing arm is adjusted to over-extend the gate closure.

The goal is to have the locking pin strike its receptacle firmly. The added pressure in the slight over-

extension of the gate aids in keeping the locking pin aligned in its receptacle.

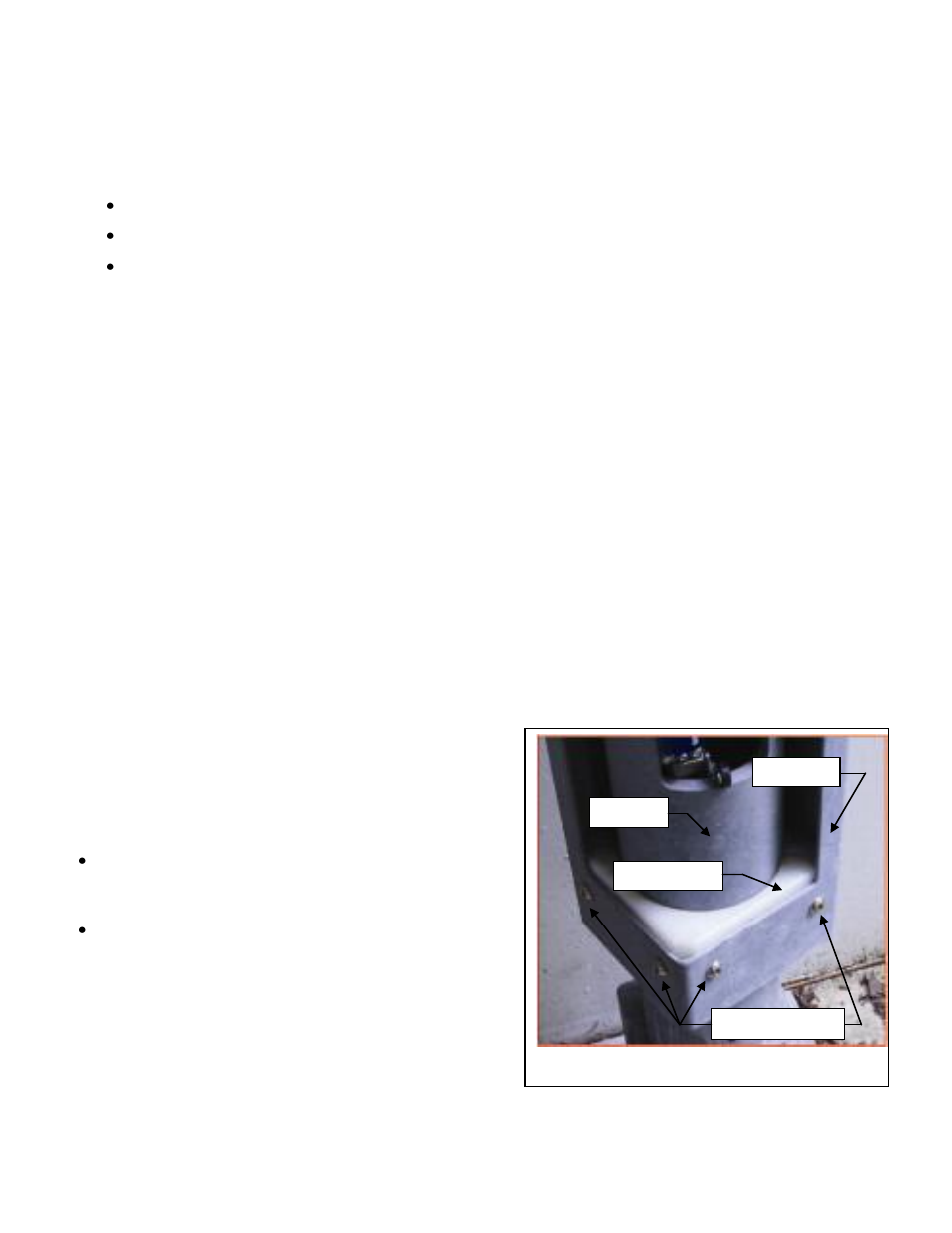

UHMW bearings and shims: Inspect the white UHMW

plastic bearings (inside the upper and lower portions of

the square post). See the photo in the Cut-away View.

The bearings are designed to wear during normal

operation and must be inspected at regular intervals and

re-shimmed or replaced, as necessary.

If the gap between the bearing and the inner tube

exceeds

⅛-inch (3mm), the bearing needs to be re-

shimmed. See Reshimming the Bearings.

If the bearing is extensively worn and ¼-inch (6mm)

or less of plastic bearing material remains, replace

the bearing. Replace both the upper and lower

bearings by following the steps in Replacing the

Bearings.

NOTE: If you plan to replace the bearings, a

replacement part kit must be ordered from

HySecurity. The kit includes the upper and lower

UHMW bearings and 16 shims.

Cut-away View

Inner tube

Lower bearing

Outer post

Bearing cap screws