Lock pin assembly – Controlled Products Systems Group HRG 220-A ST User Manual

Page 34

Installation and Maintenance Manual

20

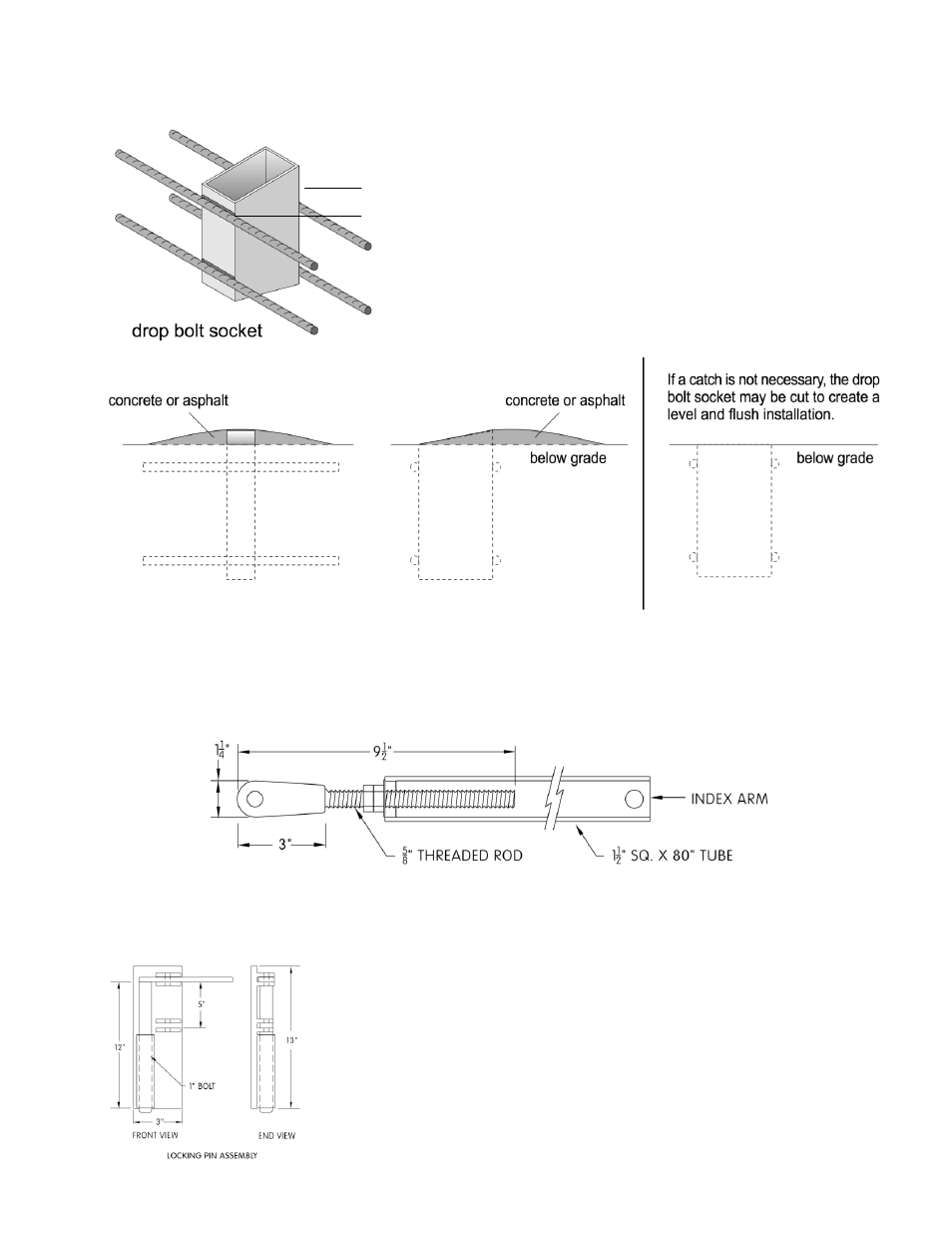

10) Mount the locking pin mechanism on the lower corner of the free end of the gate panel in such a

position that the pin penetrates 2 inches into its lock receptacle when the gate is fully closed.

11) Bury the receptacle tube in the roadway so it acts as

a socket for the locking pin. If the locking pin

assembly provided by HySecurity is not used, the

tube should have an angular cut on the tip and project

about two inches above the grade to act as a "catch"

for the locking pin. Use a 3½" x 1½

‖ tube of

appropriate length for this purpose. Use blacktop or

grout to create a mound around the exposed tube, so

passing vehicles encounter a smooth bump.

12) Adjust the threaded end of the index arm so as the free end of the gate closes, the locking pin strikes

and slides down into the receptacle. Set the index arm adjustment so the gate swings slightly past

center and the locking pin strikes the back of the receptacle. Tighten all parts of the index arm

assembly firmly (100 ft-lbs) for trouble free operation.

Lock Pin Assembly

CAUTION: If the locking pin mechanism is not used, security of

this system is adversely affected and the operator drive shaft

may be exposed to high stresses by wind loading or vandals. If

the lock pin receptacle is not built or installed to create a strike

stop for the gate, the lock pin may not always align with the

receptacle.

NOTICE: If the locking pin mechanism is not used, security of

this system is adversely affected and the operator drive shaft

may be exposed to high stresses by wind loading or vandals. If

the lock pin receptacle is not built or installed to create a strike

stop for the gate, the lock pin may not always align with the

receptacle.

2”