3 manual release – Controlled Products Systems Group 6300-080 User Manual

Page 45

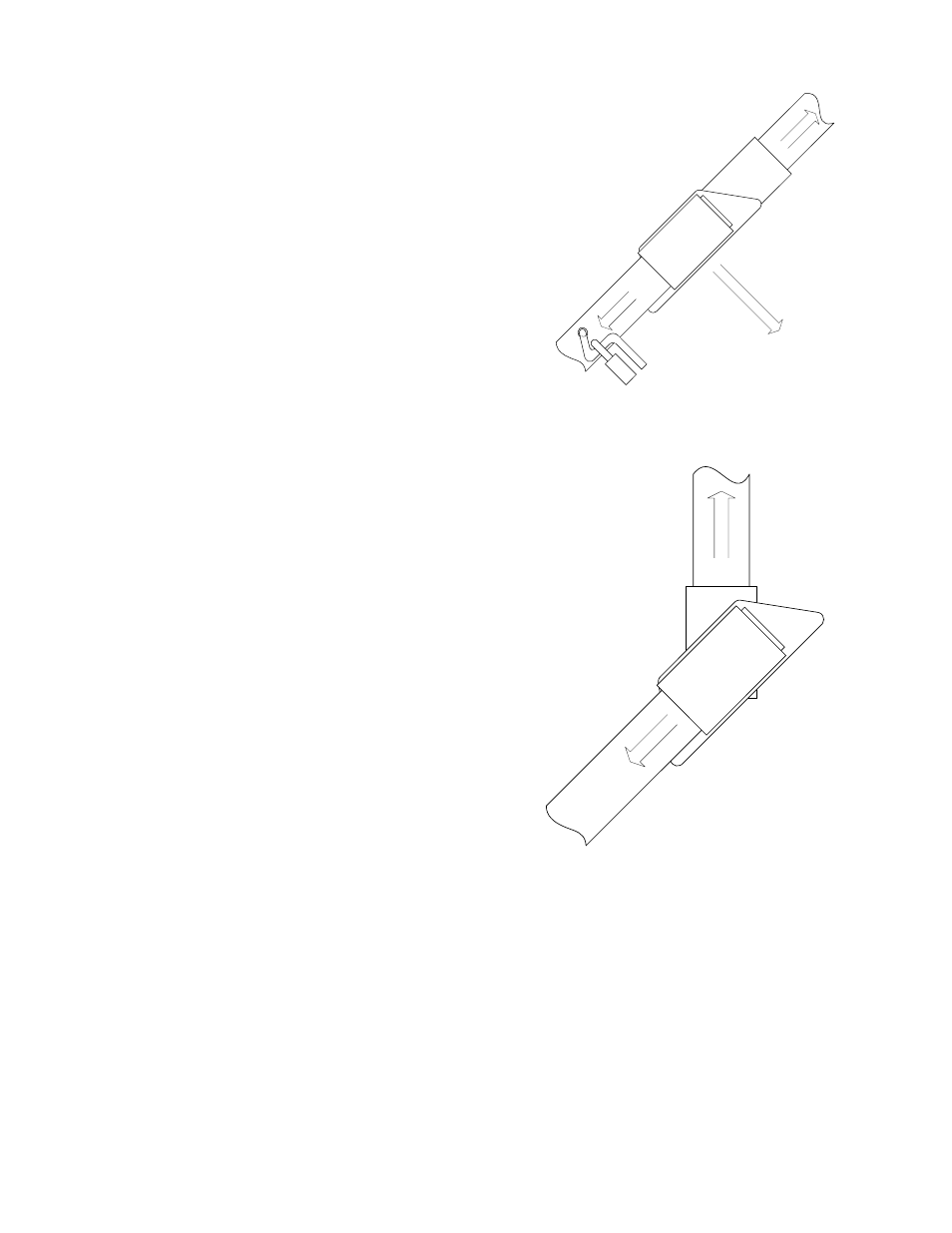

Figure 23

To

Ga

te

To

Op

er

ato

r

Cr

ank

Ar

m

C

onnect

or

Ar

m

C

onnect

or

Assem

bl

y

PUL

L!

M

anual

P

adlo

ck

R

el

eas

e P

in

1. Pull the gate arm (figure 23) that is attached to

the operator shaft away from the gate so that

the knuckle joint is slightly "broken" (figure 24).

2. Go to the end of the gate and pull it open.

• If an attempt is made to force the gate open

under normal operating conditions (AC power

present), a tamper protect circuit will detect the

forced entry and will start the motor to return

the gate to the closed position. If Gate Tracker

reporting is in use, a forced entry attempt

transaction will be sent to the DoorKing access

control system at this time.

4.3.3 Manual

Release

To

Ga

te

To

O

per

at

or

C

ran

k A

rm

C

onnector

Ar

m

Con

nec

to

r Ass

em

bl

y

In addition to FAIL-SAFE manual operation, this

operator also employees a locked release pin to place

the gate in manual operation when primary (AC) power

is removed.

• Be sure that primary (AC) and backup (DC)

power is removed or shut-off prior to placing the

gate operator in manual operation.

• Unlock and remove the padlock on the operator

crank arm (figure 23) and then pull the release

pin.

• The gate can now be manually operated.

Figure 24

6300-065-E-4-08

Page

45