2 connecting arm – Controlled Products Systems Group 6300-080 User Manual

Page 23

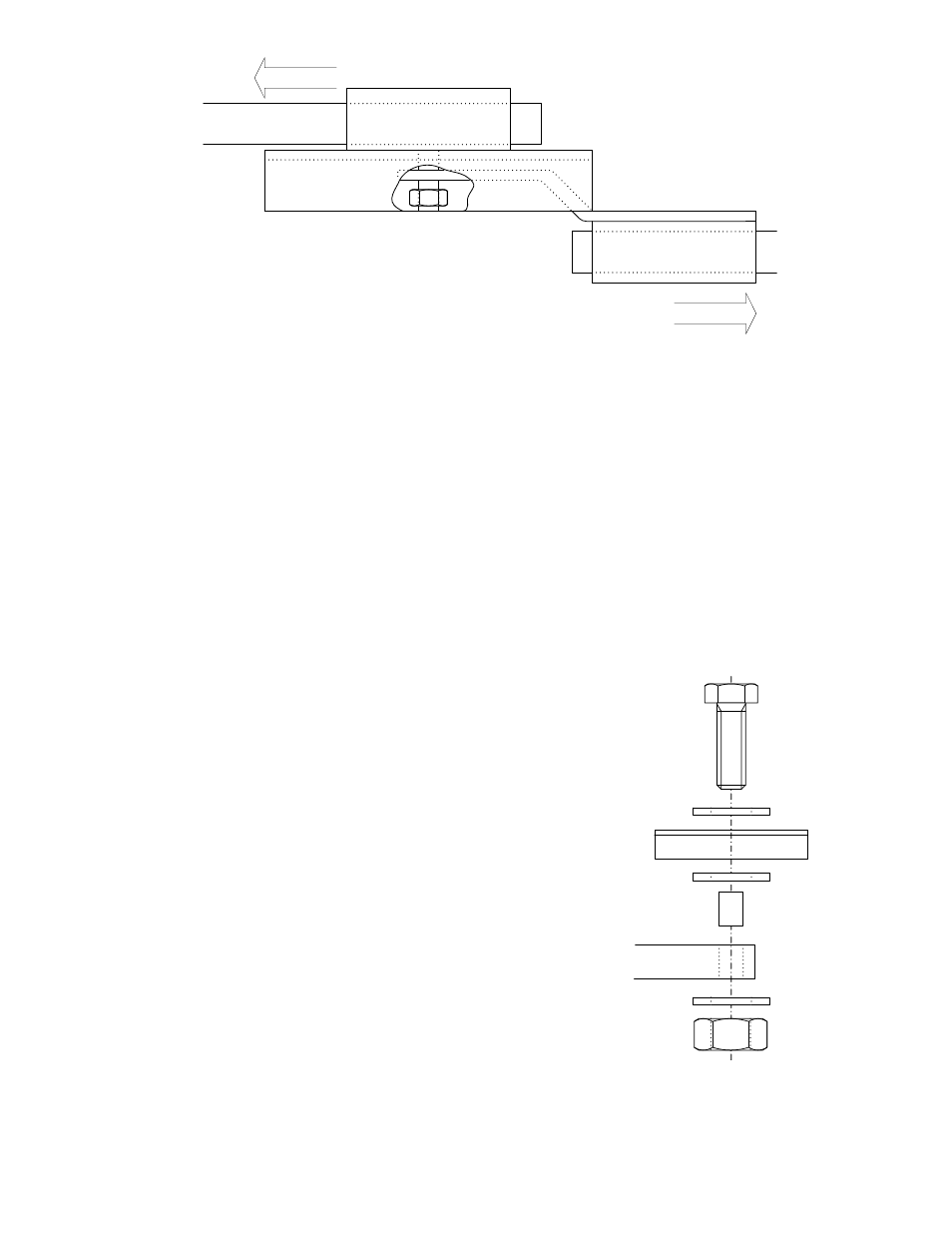

To Gate

To Operator

Figure 12

4. Slide the connector assembly (Figure 12) onto the crank arm so that the flange is away

from the gate.

5. The connector assembly must be positioned on the crank arm at the correct distance

from the operator shaft to allow the gate to open a full 90º (refer to figure 11 on the

preceding page).

6. Adjust the connector assembly on the crank arm so that the distance from the center of

the operator output shaft to the center of the pivot on the connector assembly is 24

inches. Tighten the setscrews to secure the connector in place, but do not weld at this

time.

1.4.2 Connecting

Arm

Bolt 1/2-13 x 2 1/4

1/2 Washer

Gate Bracket

Bushing

Connecting Arm

Lock Nut 1/2-13

1/2 Washer

1/2 Washer

1.

Place the gate in the full closed position.

2.

Once the crank arm assembly length is set,

slide one end of the connector arm through

the connector assembly and attach the other

end to the gate bracket as shown in Figure 13.

Attach the arm to the bottom side of the gate

bracket.

3.

Be sure that the gate is fully closed and then

tighten the three setscrews in the connector

assembly to lock the connecting arm in place.

Figure 13

6300-065-E-4-08

Page

23