Recommended position, Wiring, Specifi cations – GF Signet 2819-2823 Conductivity-Resistivity Electrodes User Manual

Page 3: Specifi cations and wiring, Black red white shield, General, Environmental requirements, Standards and approvals

3

Signet

2818-2823 Series Conductivity Sensor Instruction Manual

Specifi cations and Wiring

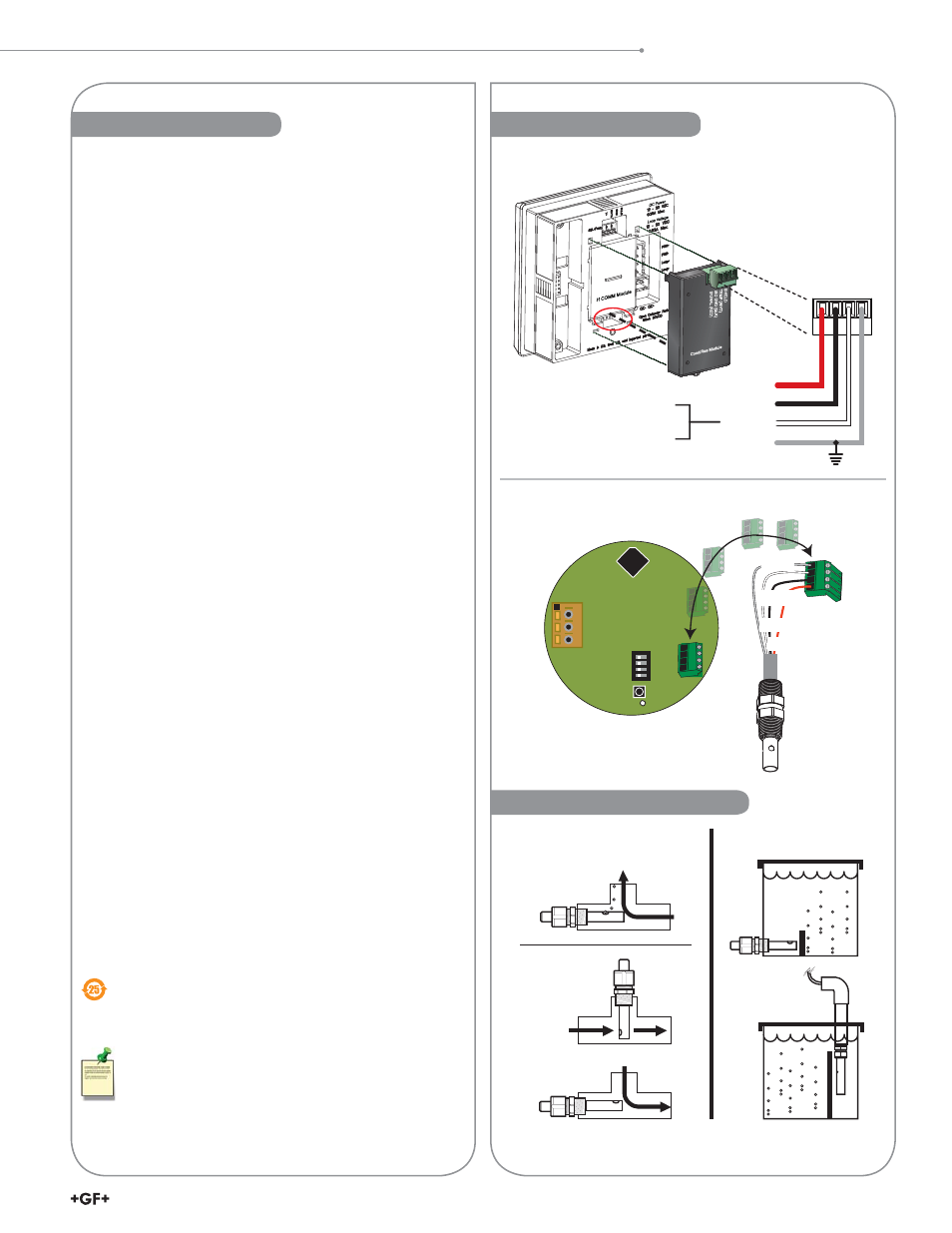

3-9900.092 Direct Conductivity/Resistivity Module

2850 Conductivity/Resistivity Sensor Electronics

*Required

installation

postition for

0.01 cell

Use caution to avoid air bubbles or sediment

trapping inside the electrode cavity.

In-line

Submersible

OR

Recommended Position

SW1

D3

1

2

3

1

2

3

4

ON

CTS

V+

Gnd

Data

Temp. IN

(WHITE)

Sensr Gnd

(SHIELD)

Signal IN

(RED)

Signal RTN

(BLK)

Wiring

Loop V

oltage

H COMM Module

DC Power

Cond/Res Module

SHIELD

TEMP

(WHT)

ISO GND (BLK)

SIGNAL

(RED)

2818 - 2823

SHIELD (SIL

VER)

TEMP

(WHT)

ISO GND (BLK)

SIGNAL

(RED)

Black

Red

White

Shield

Specifi cations

General

Cell Constant

2818

................................... 0.01

cm

-1

2819

................................... 0.01

cm

-1

2820

................................... 0.1

cm

-1

2821

................................... 1.0

cm

-1

2822

................................... 10.0

cm

-1

2823

................................... 20.0

cm

-1

Operating Range:

2818 ................................... 0.055 to 100 μS (10 kΩ to 18.2 MΩ)

2819 ................................... 0.055 to 100 μS (10 kΩ to 18.2 MΩ)

2820 ................................... 1 to 1000 μS (1 kΩ to 1 MΩ)

2821 ................................... 10 to 10,000 μS (5 to 5000 ppm)

2822

................................... 100 to 200,000 μS (50 to 100,000 ppm)

2823

................................... 200 to 400,000 μS (100 to 200,000 ppm)

Cell Constant Accuracy .......... ±2% (certified cells ±1%)

Temp. Compensation Device.. PT1000

Cable Length

Standard ............................. 4.6 m (15 ft)

Maximum ............................ 30 m (100 ft)

2818 & 2819-1 .................... 7.6 m (25 ft) max. when used

with 8850 & 8860. Do Not splice cable.

Sanitary fitting size ................. 1 in., 1½ in., 2 in.

Wetted Materials

O-Rings .................................. EPR (EPDM)

Electrodes............................... 316L Stainless Steel (1.4408, DIN 17440)

or Titanium

Sanitary fitting ......................... 316L Stainless Steel or Titanium

2822 Body .............................. CPVC

Insulator Material

2818/2819/2820/2821 .......... Carbon fiber reinforced PTFE

2823 .................................... PEEK

®

Process Connection ............... ¾ in. NPT threads;

Standard 316 SS fitting &

Optional 316 SS submersion

adapter fitting (3-2820.390)

Shipping Weight

2818/2819/2820/2821/2822 ... 0.4 kg (0.8 lb)

2823 .................................... 0.3 kg (0.6 lb)

Environmental Requirements

Temperature Accuracy ........ 0.3 °C

Max. Pressure/Temperature Ratings

2818/2819/2820/2821 Fittings:

Standard Polypropylene ..... 6.9 bar @ 100 °C (100 psi @ 212 °F)

(3-2820.392) ½ NPT 316 SS ... 13.8 bar @ 120 °C (200 psi @ 248 °F)

Sanitary Connection ........... 6.9 bar @ 120 °C (100 psi @ 248 °F)

2822........................................ 6.9 bar @ 95 °C (100 psi @ 203 °F)

2823........................................ 6.9 bar @ 150 °C (100 psi @ 302 °F)

Standards and Approvals

• RoHS

Compliant

China RoHS (Go to www.gfsignet.com for details)

Alternate wetted materials and overall lengths are

available through special order.

Cable length extensions to 100 ft. (30 m) are available

through special order.

For resistivity measurements above 10 MΩ and/or

below 20°C, maximum cable length is 25 ft. (7.6 m).