GF Signet 2764-2767 Differential DryLoc pH_ORP Electrodes User Manual

Page 5

5

Signet 275X, 276X, 277X Series pH and ORP Electrodes

5. Maintenance and Cleaning

5.1 Maintenance

Variables can affect long-term pH or ORP electrode life. For this reason, a maintenance log is recommended for trend analysis. When

storing boxed sensors, lay the sensor fl at to maximize hydration of the glass surface. Keep the glass surface wet at all times. Soak the

sensor tip in pH 4.0 buffer during system maintenance intervals. In-line applications should be plumbed with a depression (trap) so liquid

is maintained around the sensor tip. If the sensor dehydrates, soak the sensor tip in pH 4 buffer for 24 to 48 hours, then visually inspect

the electrode for surface cracks, swelling, or discoloration. Severely dehydrated electrodes cannot be restored to normal operation.

5.2 Cleaning

Cleaning techniques vary depending on the type of coating present on the glass electrode surface or reference junction.

• Soak electrodes in pH 4 buffer or KCl solution after cleaning.

• Soft coatings can be removed by vigorous stirring, or with directed spray of an applicable detergent or solvent onto the glass surface.

Chlorine bleach or mild detergent can be used to remove soft coatings. Always rinse electrode tip in clean water after cleaning.

• Hard coatings can be chemically removed. Use the least harsh chemical which will remove the contaminant within two (2) minutes

without attacking the materials of construction. e.g. calcium carbonate may be removed with a 5% HCl (muriatic acid) solution.

• Oily or organic coatings can be removed with detergents or an appropriate solvent that does not attack the materials of construction;

e.g. isopropyl alcohol may be used but acetone must be avoided to prevent damage to the CPVC sensor body.

• ORP platinum electrode surfaces can be gently wiped with a wet paper towel. More stubborn coatings can be removed by gently

sanding with 600 grit wet and dry silicone or carbide sandpaper, jewelers rouge, crocus cloth, or very fi ne steel wool.

5.3 276X Series Differential Electrodes

Differential electrodes have a replaceable salt bridge and the

electrolyte chamber can be refi lled. The electrolyte chamber

should be full. If any fl uid is audible when shaken, the chamber

should be refi lled. Refi ll the electrolyte chamber when the

electrode offset exceeds 50 mV. Replace the salt bridge when

performance becomes sluggish or if the output is erratic or

inaccurate.

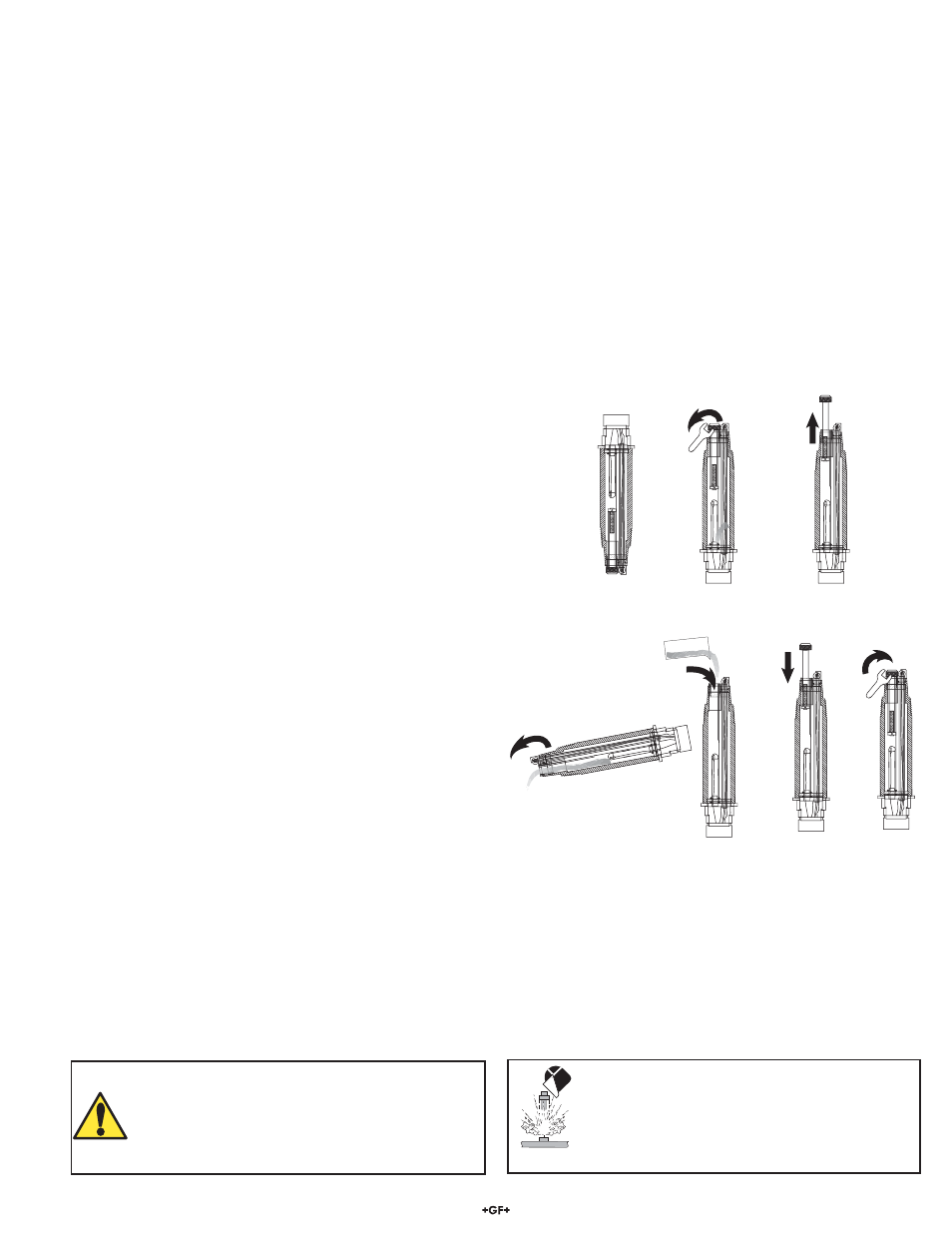

Replacing the Salt Bridge

Parts Required: Salt Bridge (order number 3864-0001) and

Differential

Reference

Solution

(order

number

3864-0002)

Tools Required: Small pliers

Procedure:

1. Remove sensor from mounting.

2. Hold upside down and unscrew salt bridge using a pair of small

pliers. Be careful not to damage the glass bulb!

3. Drain the depleted reference solution and dispose of properly.

4. Fill reference chamber with fresh reference solution (approx.

30 ml).

5. Replace salt bridge and screw fi nger tight. Solution will drip out

while screwing in salt bridge.

Use pliers to turn approximately ¼ turn past fi nger-tight.

6. Perform calibration (standard and slope) before returning the

system to service.

WARNING!

Wear appropriate eye, face, hand, body, and

respiratory protection when using chemicals or

solvents.

NOTE:

The refi llable electrolyte chamber in 276X series

differential electrodes may leak during storage and

shipping. Check the fl uid and refi ll before installation

if necessary.