GF Signet 525 Metalex Flow Sensor User Manual

Page 3

3

Signet 525 Metalex Flow Sensor

8. Maintenance

The 525 sensor requires little or no maintenance of any kind, with the exception of an occasional sensor/paddlewheel cleaning.

7. Sensor Removal Procedure

1. Depressurize and drain pipe.

2. Remove the four sensor fl ange bolts and lock washers. Pull

upward on the sensor fl ange with an alternating twisting

motion.

9. Rotor Replacement Procedure

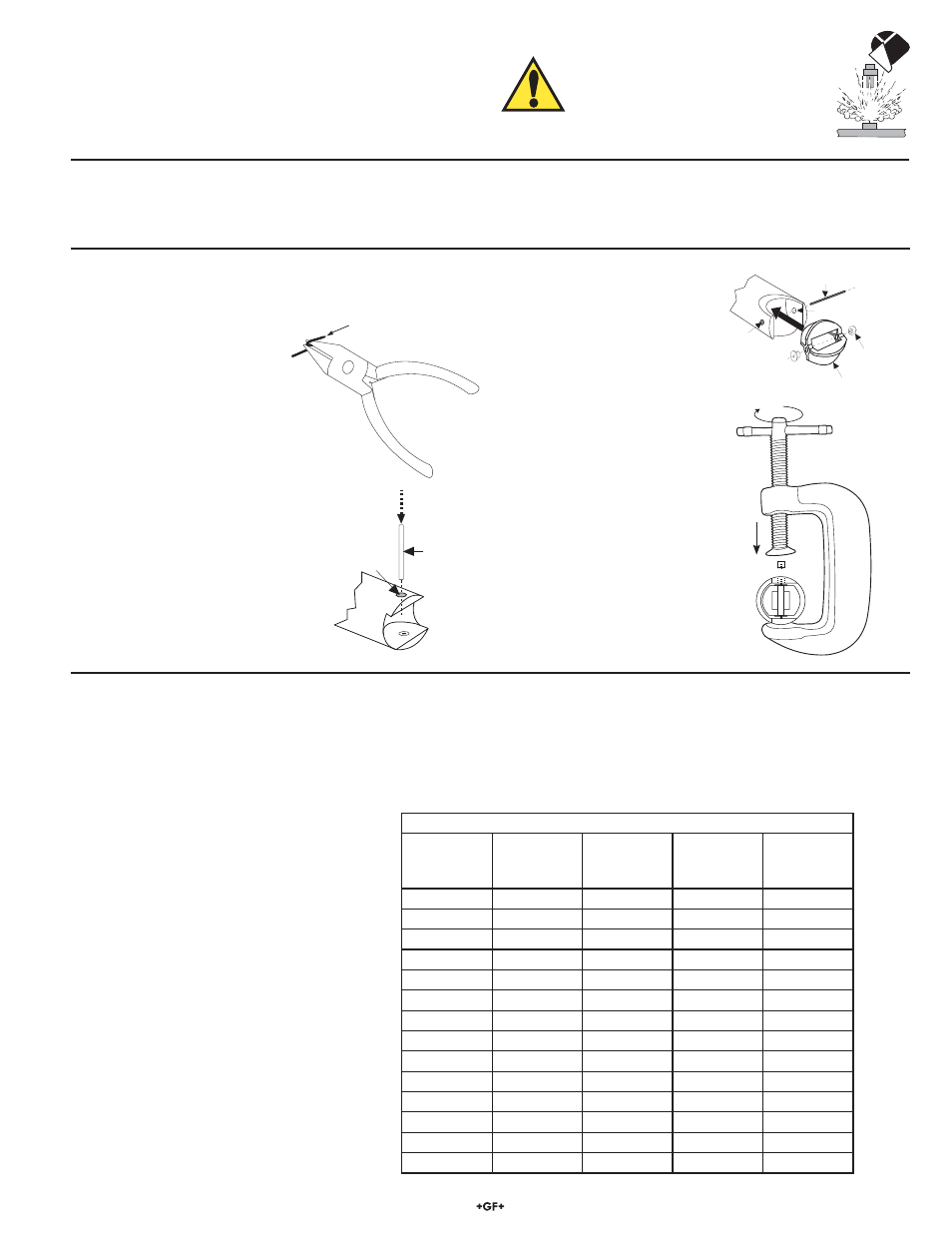

1. With a small pair of needle-

nose pliers, fi rmly grip the

center of the rotor pin (axle)

and with a twisting motion,

bend the rotor pin into an

"S" shape. This should pull

the ends of the pin out of the

retainers and free the rotor

assembly.

Rotor Pin

Existing

Retainer

New

Bearings

Rotor

Assembly

Punch

Retainer

Rotor Pin

10. K-Factors

The K-Factor is the number of pulses the sensor will generate for each engineering unit of fl uid which passes. They are listed in U.S.

gallons and in liters. For example, in a 1 inch SCH 40S stainless steel pipe, the sensor generates 266.17 pulses per gallon of fl uid

passing the rotor. K-Factors are listed for SCH 40S stainless steel pipes up to 12 inch.

Conversion Formulas

1 U.S. gallon =

0.003785 cubic meters

0.000003069

Acre

feet

8.3454 pounds of water

SCH 40S STAINLESS STEEL PIPE PER ANSI B36.19

PIPE

SIZE

K-FACTOR

PULSES/

U.S. GAL

K-FACTOR

PULSES/

U.S. LITER

A-FACTOR

GPM/Hz

A-FACTOR

LPM/Hz

1/2 IN.

873.03

230.66

0.0687

0.2601

3/4 IN.

515.41

136.17

0.1164

0.4406

1 IN.

266.17

70.322

0.2254

0.8532

1 1/4 IN.

148.84

39.324

0.4031

1.5258

1 1/2 IN.

107.98

28.528

0.5557

2.1032

2 IN.

64.808

17.122

0.9258

3.5042

2 1/2 IN.

44.685

11.806

1.3427

5.0822

3 IN.

28.579

7.5506

2.0994

7.9464

4 IN.

16.302

4.3070

3.6805

13.931

5 IN.

10.237

2.7046

5.8611

22.184

6 IN.

7.0057

1.8509

8.5645

32.416

8 IN.

3.9641

1.0473

15.136

57.289

10 IN.

2.4690

0.6523

24.301

91.981

12 IN.

1.6894

0.4463

35.516

134.43

WARNING!

Do not remove from pressurized lines.

Wear safety goggles and faceshield

during installation/service.

2. Remove rotor pin retainer from

each side by gently tapping it

inwards using a punch. Install a

new retainer into the sensor body

with its rotor pin clearance hole

inward. Only install one retainer at

this time.

3. Insert the new rotor assembly

and bearings into the rotor

housing of the sensor and

place the new rotor pin (axle)

through the open end of

the rotor housing, through

the rotor and bearings, and

into the previously installed

retainer.

4. Using a vise or C-clamp, press

the second retainer into the hole

in the sensor body while lining

up the rotor pin with the center

of the retainer hole.

NOTE

: A hammer and center punch

can also be used if a clamp or vice

is not available