GF Signet 525 Metalex Flow Sensor User Manual

Page 2

2

Signet 525 Metalex Flow Sensor

Signet Metalex Saddle Fittings (Sensor PN P525-3/-3S)

Pipe (in.)

Fitting

Code

2.00

P526-1020

159 000 484

2.50

P526-1025

159 000 485

3.00

P526-1030

159 000 486

4.00

P526-1040

159 000 487

5.00

P526-1050

159 000 488

6.00

P526-1060

159 000 489

8.00

P526-1080

159 000 490

10.0

P526-1100

159 000 491

12.0

P526-1120

159 000 492

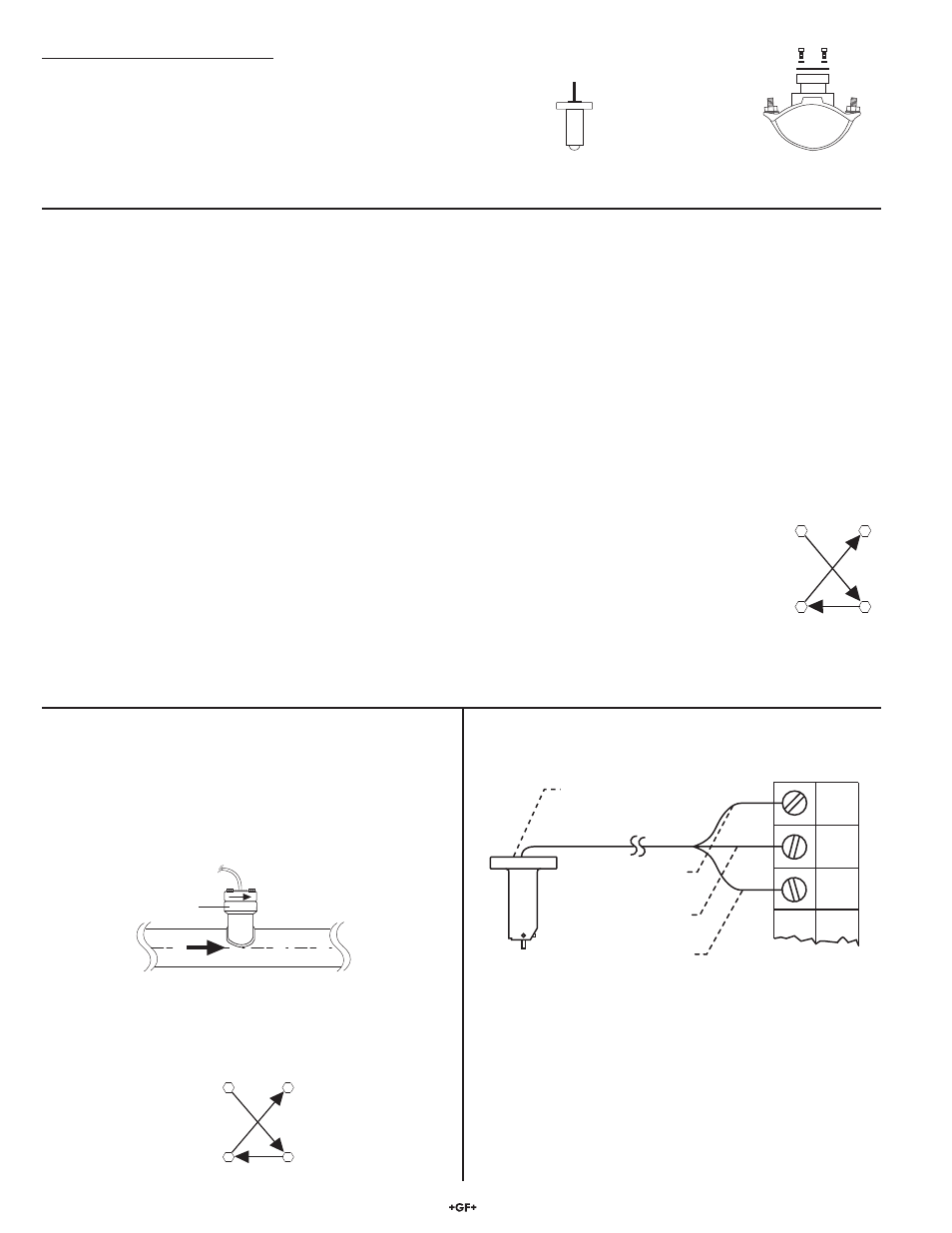

4. Fitting Installation, Required Hardware

Signet Metalex Tee & Mini-Tap Fittings, P526-2XXX

• 0.5 to 1 inch pipes, P526-2 series fi tting required

• 1.25 to 12 inch pipes: P526-2 series fi tting and 27 mm

(1-1/16 in.) diameter drill required

• Mini-Tap fi ttings are welded onto the pipe and are used with

Signet 525-1 and 525-2 sensors.

Signet Metalex Saddle Fitting, P526-1XXX

• 27 mm (1-1/16 in.) diameter drill required

Saddle type fi ttings are strapped to the pipe and are used with

Signet 525-3 sensors. Welds MUST be made by a certifi ed welder

who is licensed to weld stainless steel and other high carbon

grade steels.

4.1 Installation, Tee & Mini-Tap Fittings

1. Select an appropriate mounting location as outlined in

sections 1 and 2.

2. Depressurize and drain pipe.

3. Use the following welding and installation procedures

appropriate for your fi tting/pipe size:

Signet Tee Fittings, 0.5 to 1 inch:

• Insert pipe into fi tting socket

• Make sure the pipe is parallel to the bottom of the Mini-Tap

fi tting.

• Weld pipe into place.

1

4

2

3

U-bolt

torque

pattern

5. Sensor

Installation

1. Set the gasket supplied with the fi tting onto the fi tting fl ange,

making sure the holes align.

2. Remove the red rotor protection cap and insert the sensor

into the fi tting, making sure not to bump the rotor assembly.

Make sure the arrow on the side of the sensor is pointing in

the direction of fl ow.

6. Sensor

Wiring

Blk

F-

Red

F+

Shld.

525

black

(AC signal out)

red

(AC signal out)

silver

(ground)

Instruments

1/2 in. NPT

conduit port

Flow

Flow sensor

arrow

Fitting

flange

3. Slip two washers onto each bolt and insert the bolt/washer

onto each of the four fi tting fl ange holes.

4. Snug all four fl ange bolts in a criss-cross pattern. Using a

torque wrench (when possible), torque the fl ange nuts in a

crisscross pattern to 52 foot pounds.

1

4

2

3

Flange

bolt torque

pattern

+GF+

Saddle Fitting,

hardware included

525-3

Sensor

(525-3S for stainless steel pin)

Wetted fitting materials:

Ductile Iron, 347 SS,

Carbon Steel,

Buna-N/Neoprene

Signet Mini-Tap Fittings, 1.25 to 12 inch:

• Drill a 27 mm (1-1/16 in.) diameter hole completely through the

ONE surface of the pipe. Thoroughly deburr inner and outer

edges of hole.

• Tack weld the Mini-Tap fi tting onto the pipe, making sure the

hole in the pipe is lined up with the Mini-Tap fi tting hole.

• Weld the Mini-Tap fi tting onto the pipe.

4.2 Installation, Saddle Fittings

1. Select an appropriate mounting location as outlined in

sections 1 and 2.

2. Drill a 27 mm (1-1/16 in.) diameter hole completely through

the TOP surface of the pipe. Thoroughly deburr inner and

outer edges of hole.

3. Place the Buna-N/Neoprene saddle O-ring over the pipe hole

(small hole side towards pipe). Position the saddle fi tting

over the O-ring, making sure the O-ring

centers on the underside fi tting ridge.

Center saddle fi tting and O-ring over the

pipe hole, then strap the fi tting to the pipe

with the two U-bolts. Snug all four nuts

in a criss-cross pattern. Using a torque

wrench (when possible), torque the

U-bolts in a criss-cross pattern to 52 foot pounds.

• Use 2-conductor shielded cable for cable splices to 60 m

(200 ft).

• Maintain cable shield through splice.

• Shield the unjacketed silver (ground) wire using electrical tape

to prevent potential noise interference and/or shorting hazards.