Flow sensor insertion/removal – GF Signet 3519 Flow Wet-Tap Valve User Manual

Page 3

3

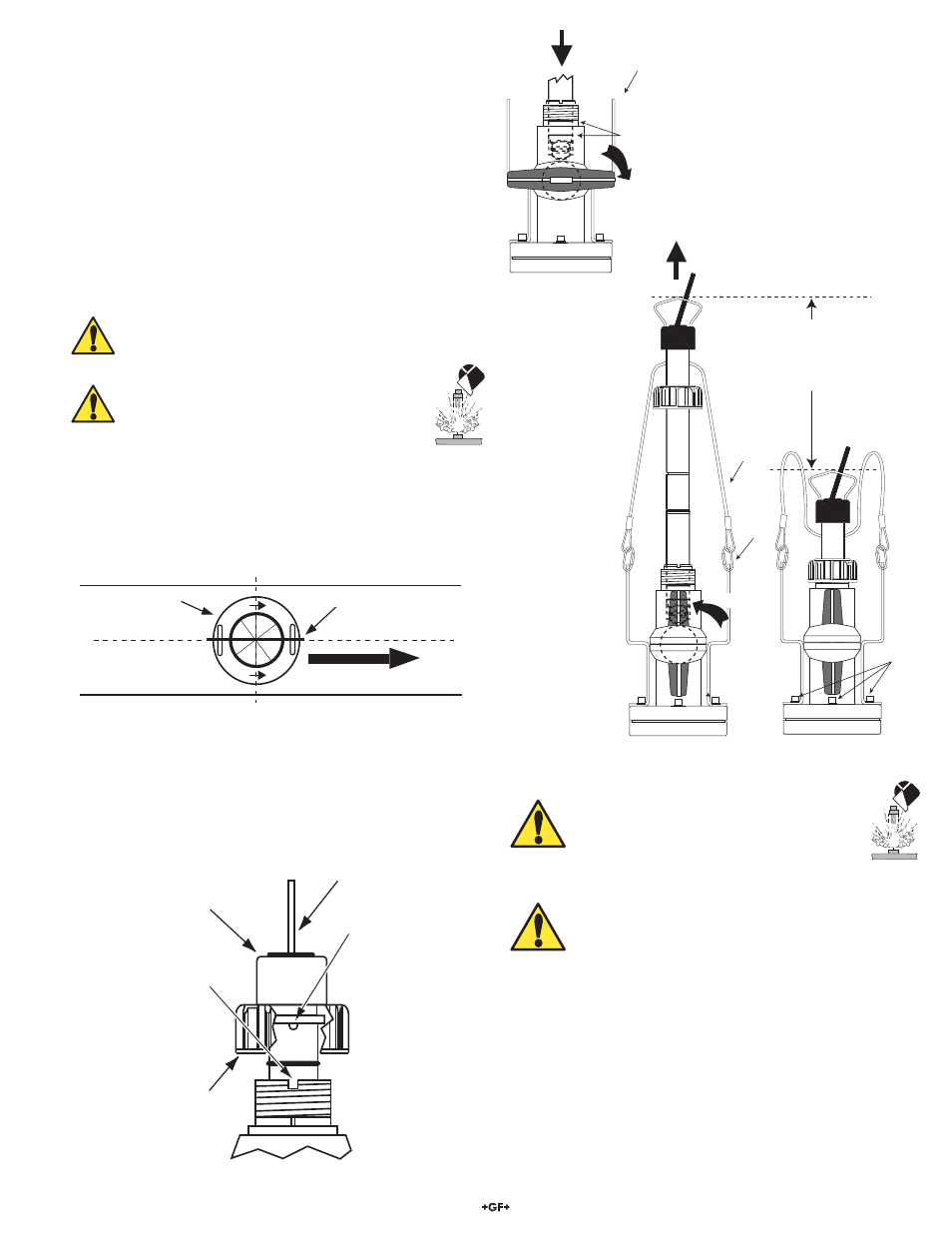

Signet 3519 Flow Wet-Tap Assembly

clamps

safety

cable

Hex

bolts

(6 ea.)

OPEN

SENSOR

STROKE AREA

P3 sensor = 197 mm (7.75 inches)

P4 sensor = 229 mm (9 inches)

P5 sensor = 305 mm (12 inches)

black conduit

cap

PROCESS PIPE

(TOP VIEW)

direction of flow

sensor bale

Figure 3

Figure 2

O-rings

brackets

CLOSED

Figure 1

7. Align the tabs under the sensor cap with the notches on the

fi tting insert and tighten the sensor cap (Figure 4).

• HAND TIGHTEN ONLY. DO NOT use any tools that may

damage plastic parts.

Figure 4

sensor

bale

sensor

cap

tab

black

conduit

cap

notch

3. Flow Sensor Insertion/Removal

To insert the fl ow sensor:

1. Lubricate O-rings with a non-petroleum based, viscous

lubricant (grease) compatible with the system.

2. Carefully insert the sensor into the 3519 valve assembly until

the fi rst two O-rings seat inside the bore (Figure 1).

• Do not damage the rotor on closed ball valve.

3. Using the clamps, attach the sensor safety cable to the

3519 assembly brackets (hand tighten only).

4. Pull

the

fl ow sensor upward to remove slack in the safety

cables (Figure 2).

WARNING: Safety cables are factory installed at precise

length. DO NOT attempt to service or replace safety

cables.

WARNING: System pressure must be 25 psi

or less prior to sensor insertion or removal.

5. Open the ball valve (Figure 2).

6. Using a twisting motion, push the fl ow sensor into the 3519

assembly.

• Turn the sensor so the arrows on the black conduit cap

point in the direction of fl ow.

• When properly aligned, the sensor bale will be parallel with

the pipe (Figure 3).

To remove the fl ow sensor:

WARNING: System pressure must be

25 psi or less prior to fl ow sensor insertion

or removal. Stay clear of sensor stroke

area and safety cable during sensor

removal.

WARNING: Check the six (6) Hex bolts (Figure 2)

prior to unscrewing the sensor cap. If bolts are loose,

tighten securely before proceeding.

1. Unscrew the sensor cap. (DO NOT use any tools that may

damage plastic parts.)

2. Carefully pull the fl ow sensor upward with a twisting motion

until the safety lanyards are fully extended (Figure 2).

3. Close the ball valve (Figure 1).

4. Loosen the relief plug to depressurize the sensor area.

5. Disconnect the sensor safety cable clamps from the 3519

assembly brackets.

7. The sensor can now be safely removed.