Signet fittings, Wet-tap valve installation – GF Signet 3519 Flow Wet-Tap Valve User Manual

Page 2

2

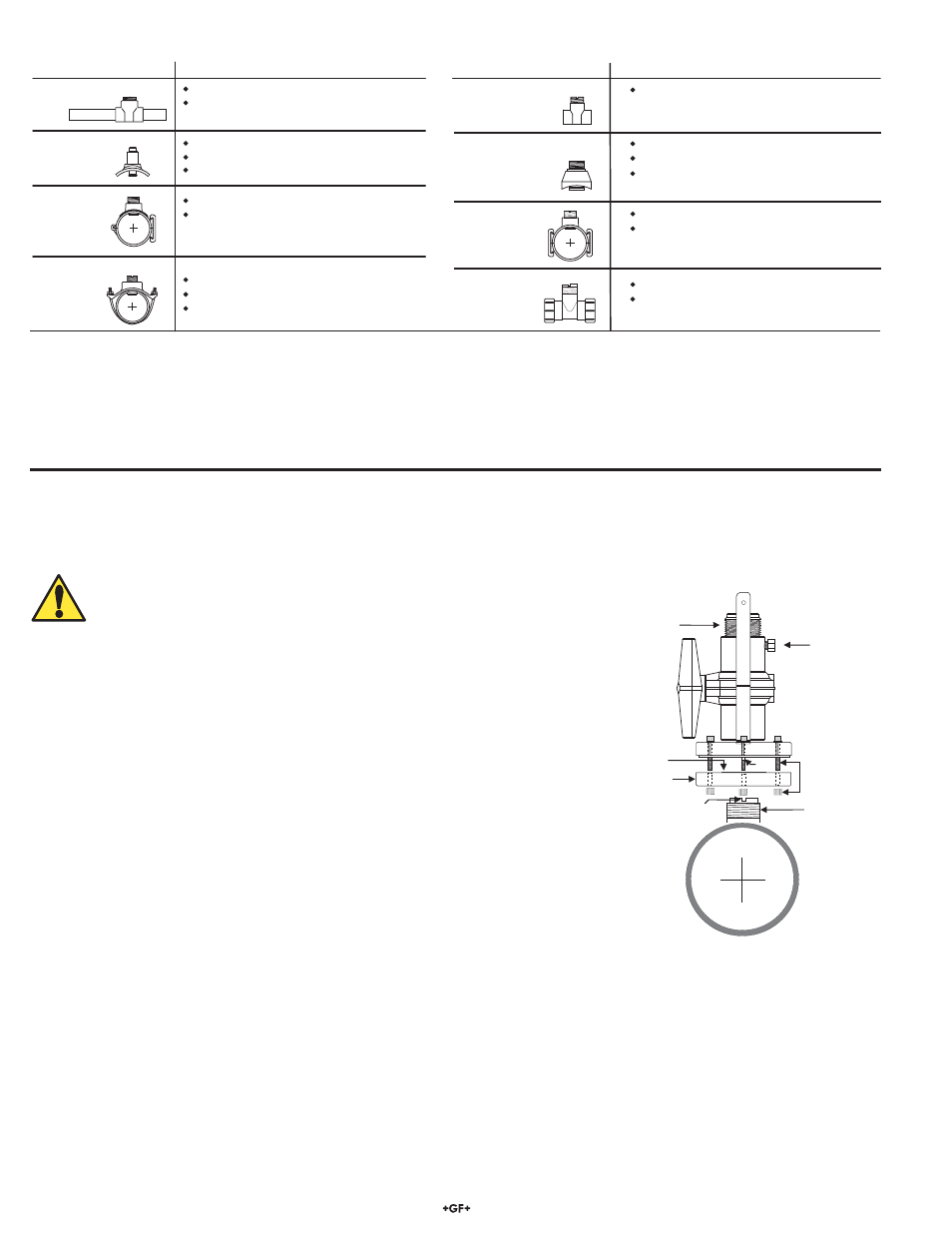

Signet 3519 Flow Wet-Tap Assembly

3. Signet Fittings

Type Description

2 to 4 inch, cut 1-7/16 inch hole in pipe

Over 4 inch, cut 2-1/4 inch hole in pipe

Special order 14 in. to 36 in.

0.5 to 4 inch versions

PVC or CPVC

2 to 4 inch, cut 1-7/16 inch hole in pipe

6 to 8 inch, cut 2-1/4 inch hole in pipe

Available in 10 and 12 inch sizes only

Cut 2-1/2 inch hole in pipe

Weld in place using solvent cement

0.5 to 2 inch versions

Carbon steel &

stainless steel

threaded tees

Carbon steel &

stainless steel

Weld-on

Weldolets

2 to 4 inch, cut 1-7/16 inch hole in pipe

Over 4 inch, cut 2-1/4 inch hole in pipe

See section 4 below for details

For pipes DN 65 to 200 mm

Requires a 30 mm diam. hole in the pipe

For pipes from DN 15 to 50 mm

PP or PVDF

Type Description

Plastic tees

Metric

PVC-U

Saddle

Metric

Union

Fitting

PVC

Clamp-on

Saddles

Iron

Strap-on

saddles

PVC

Glue-on

Saddles

Consult the Signet Measurement and instrumentation Catalog for a complete listing of installation fi ttings.

Valve handle

(shown in

open position)

Pressure

relief plug

Align notch and key

under wet tap flange

parallel with pipe.

Allen bolts

and hex nuts

Support plate

Viton O-ring

Key

Sealant

1-1/4 X 11-1/2 in.

NPSM thread

4. Wet-Tap Valve Installation

The Signet 3519 Flow Wet-Tap Assembly attaches directly to Signet installation fi ttings to enable fl ow sensor removal without system

shutdown. It consists of a fl ange and support plate which thread onto the pipe fi tting insert, and a PVC ball valve through which an

extended length fl ow sensor is inserted into the pipe.

CAUTION: The 3519 Flow Wet-Tap Valve may only be installed into, and

removed from, non-pressurized systems (0 psig).

Procedure

1. Remove six hex nuts and bolts from the Wet-Tap fl ange. Separate the support plate

from the main assembly. Be sure that the Viton O-ring is properly seated in the

support plate groove.

2. Apply sealant to the pipe fi tting insert threads to prevent leaks.To eliminate any

leakage, the valve can be sealed to the fi tting using one of these two methods:

1. Use a silicone RTV such as “GE Sealants and Adhesives Silicone II”.

2. Use a PVC cement such as Christy’s “Red Hot Blue Glue” (for PVC fi ttings) or a

similar PVC pipe cement.

NOTE: This will permanently bond the valve to the installation fi tting and the

fast drying period will not allow for errors in the installation process.

3. Screw support plate onto pipe fi tting insert (O-ring side facing up). It must be

threaded completely down until the notches at the top of the pipe fi tting insert

are exposed.

4. Mount the main Wet-Tap Assembly on the support plate. Make certain the

alignment keys on the fl ange mate with the notches on the pipe fi tting insert.

5. Loosen support plate (holding the main Wet-Tap Assembly in place) until it resists

slightly. Loosen an additional 1/4-turn to seat O-ring.

6. Replace the six hex nuts and bolts to secure the Wet-Tap Assembly in place. Adjust the support plate position as necessary

to align screws.

7. Check the pressure relief plug on Wet-Tap Assembly. It must be closed fi nger tight to prevent leaks.

8. Close ball valve by turning the handle to the fully closed position (parallel with pipe).