Burkert Type 8697 User Manual

Page 21

21

Fluid installation

8.2.

installing the process valve

Thread type and dimensions can be found in the corresponding data

sheet.

→

Connect the valve according to the operating instructions for the

valve.

8.3.

pneumatic connection of the

pneumatic control unit

Danger!

risk of injury from high pressure in the equipment/device.

▶ Before working on equipment or device, switch off the pressure

and deaerate/drain lines.

procedure:

→

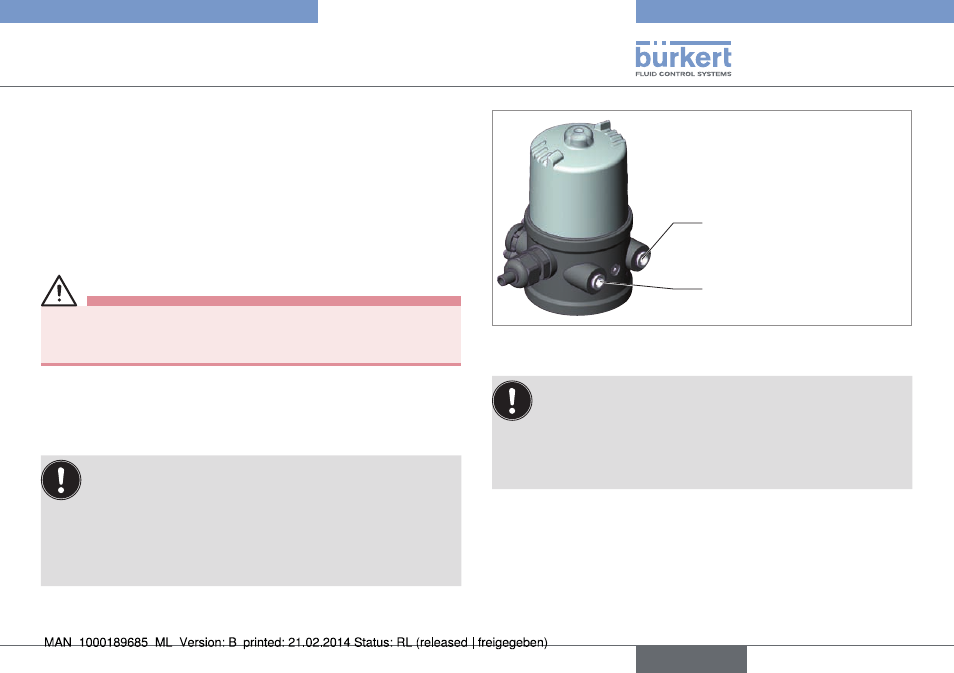

Connect the control medium to the pilot air port (1)

(3 to 7 bar, oil, water and dust-free instrument air).

→

Attach the exhaust airline or a silencer to the exhaust air port (3).

Important information for the problem-free functioning of the

device:

▶ The installation must not cause back pressure to build up.

▶ Select a hose for the connection with an adequate cross-section.

▶ The exhaust air line must be designed in such a way that no water

or other liquid can get into the device through the exhaust air port.

Exhaust air port

label: 3

Pilot air port

label: 1

Fig. 16: Pneumatic connection

Caution:

(Exhaust air concept):

In compliance with degree of protection IP67, an exhaust air

line must be installed in the dry area.

Keep the adjacent supply pressure always at least 0.5 – 1

bar above the pressure which is required to move the actuator

to its end position.

english

Type 8697