Troubleshooting guide – ClimaCool UGW Manual User Manual

Page 65

63

www.climacoolcorp.com

Troubleshooting Guide

WARNING!

The troubleshooting guidelines recommended in this section

could result in exposure to electrical safety hazards . Please

refer to the safety warnings provided in this manual . Failure

to follow all of the recommended safety warnings provided

could result in death or serious injury . When possible,

disconnect all electrical power including remote disconnects

before servicing . Follow proper lockout-tagout procedures .

Only a qualified licensed electrician or persons trained to

handle live electrical components should only be allowed to

work with energized electrical components .

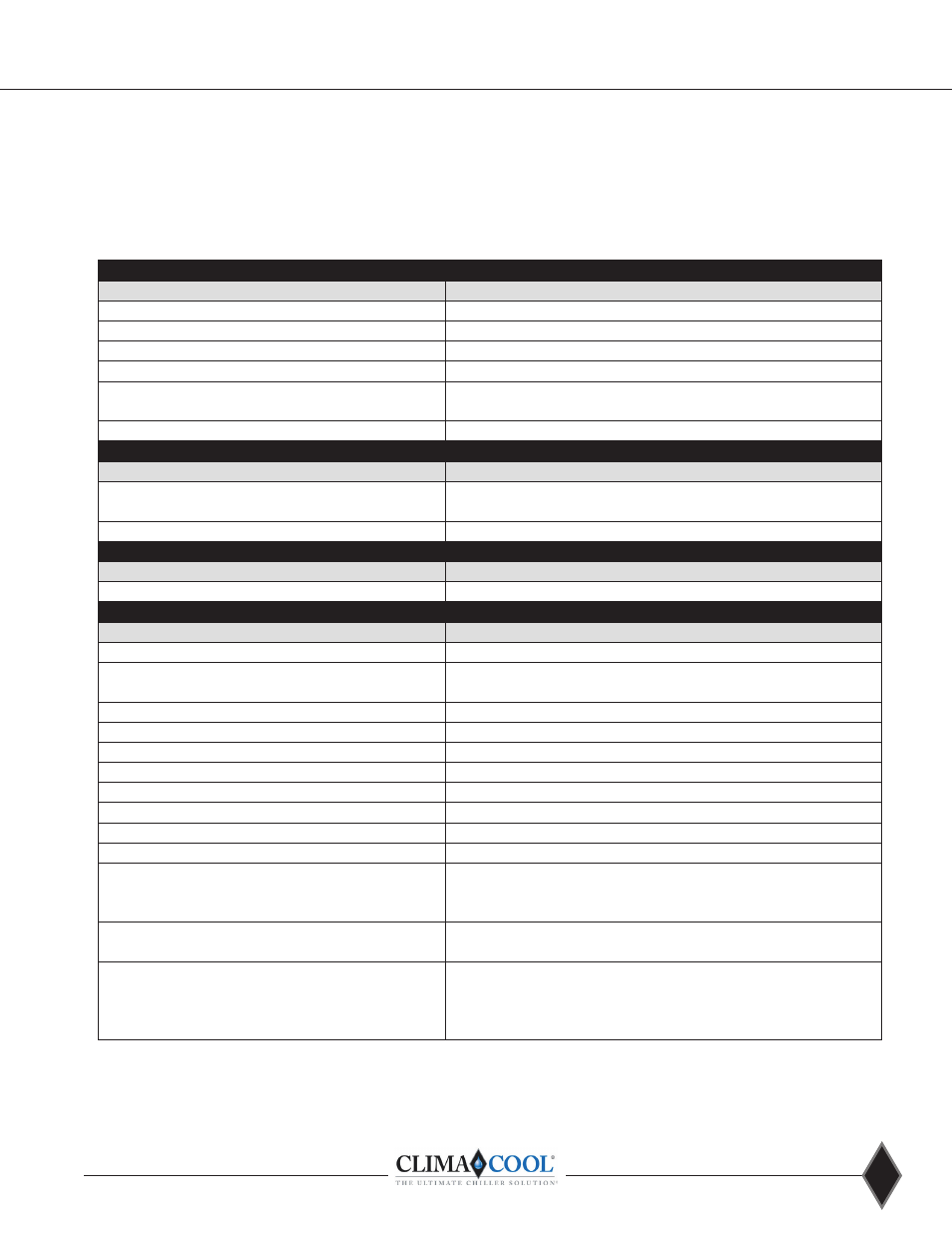

Table 4

Chiller Will Not Start

Possible Cause

Remedy

Power off

Check main disconnect switch.

Main line open

Check main fuses.

Incorrect wiring

Check the wiring diagram.

Loose terminals/connections

Tighten the terminal connections.

Control circuit open

Check interlocks with auxiliary equipment, pressure and

temperature controls.

Improper phasing of main power

Change any two of three phases of main power.

Compressor Hums But Does Not Start

Possible Cause

Remedy

Low voltage

Check at main power entry and unit power entry (consult

power company if low).

Phase loss

Check power wiring and fuses.

Compressor Runs But Does Not Cool

Possible Cause

Remedy

Improper phasing of main power

Switch any two of three phases of main power.

Compressor Cuts Out On Low Pressure Safety Control

Possible Cause

Remedy

Main chilled water valve closed or restricted

Open valve to full open position.

Module chilled water isolation valves, if

provided, closed or restricted

Open valves to full open position.

Refrigerant storage

Check for leaks – add refrigerant.

No load on water chiller

Check water pump operation.

Restriction in liquid line

Plugged liquid line drier – replace liquid line drier.

Expansion valve clogged or inoperative

Repair/replace the expansion valve.

Low discharge pressure

Raise and control discharge pressure within design limits.

Low water flow through the cooler

Check water flow through the cooler.

Chilled water temperature too cold

Raise water temperature setpoint.

Fouled evaporator brazed plate heat exchanger

Clean-in-place heat exchanger as described on page 22.

Improper chilled water circulation

Use an ample sized cleanable strainer in the chilled water

circuit; make certain the strainer is clean to insure full flow of

chilled water (strainer screen must be 60 mesh minimum).

Faulty suction pressure transducer

Verify transducer calibration using a calibrated manifold gauge

and replace if defective.

Wrong suction pressure cutout setpoint

Verify suction pressure cutout setpoint to be set equal to the

corresponding leaving chilled solution freeze temperature

equivalent pressure on a PT chart. (i.e. If the solution freeze

point is 32

o

F, the equivalent pressure setpoint will be 101 psig).

43 .