Refrigeration system re-processing and charging, Test the valve, Test the interface board – ClimaCool UGW Manual User Manual

Page 53: Troubeshooting guide

51

www.climacoolcorp.com

Refrigeration System Re-Processing and Charging

Test the Valve

The resistance of the motor winding may be tested without

opening the system .

1 . Remove power from the external controller and/or

interface board .

2 . Remove the valve leads from interface board .

3 . Measure the resistance between the black and white

leads of the valve . Resistance should be 75 ohms with

the valve at room temperature or approximately 65 ohms

if the valve is at -40°F .

4 . Measure the resistance between the green and red leads .

This value should be within ± 5% of the resistance between

the black and white leads .

5 . Measure the resistance from any lead to valve body .

Resistance should be infinite, that is to say, open.

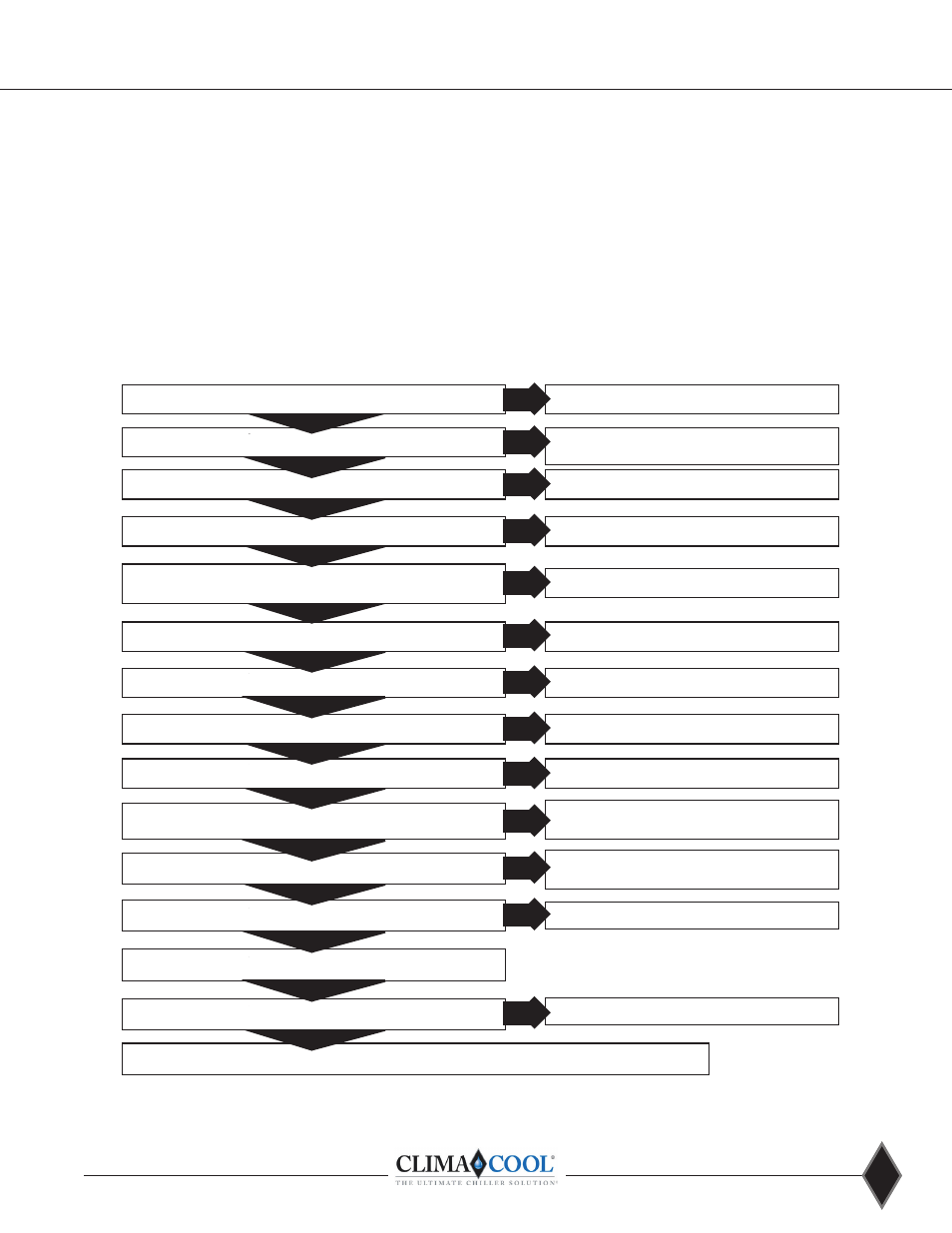

Test the Interface Board

The flow charts on the following page are designed to

assist in diagnosing a possible interface board failure . All

measurements should be made with a Digital Multimeter .

Troubeshooting Guide -

Interface Board Operating on External Signal (4-20 ma or 0-10 VDC)

Note: Before testing the interface board, make certain the valve is operating . See “Test the Valve” instructions .

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO

NO

NO

NO

NO

NO

NO

NO

NO

1. Is there 24V AC at terminals 24V + 24V-?

Repair or replace power supply or power supply

wiring .

Check wiring for polarity . Transformer should

NOT be a grounded secondary type . Replace if

necessary .

Replace the transformer with an isolated

secondary type .

Shut off power to interface board and correct

wiring .

Test the step motor . If operational, replace the

interface board .

Test the step motor . If operational, replace the

interface board .

Shut off power to interface board and external

controller . Correct input signal observing polarity .

Test or replace external controller .

Shut off power to interface board and external

controller and correct wiring .

Shut off power to interface board and external

controller and move pin jumper to correct

location .

First make sure input at terminal +4-20 & -4-20 is

greater than 4 ma . If so, repair wiring or replace

pumpdown relay .

Test the step motor . If operational, replace the

interface board .

Interface board if defective . Replace interface

board .

2. Is the fuse insalled and intact?

3. Is the 24V transformer of the isolated secondary type?

4. Is the valve connected to terminals (black, white, green,

red) with wire colors correct?

5 . Connect voltmeter on AC scale to the Black and White

valve terminals . Interrupt and restore power to the

interface board. Does the meter read 12-14 volts AC?

6 . Repeat above test using Red and Green terminals . Does

the meter read 12-14 volts?

7. Are wires for external signal connected to terminals +4-20

& -4-20?

8. Is external signal present? Signal should be 4-20 MA at 12

volts DC or 0-10 VDC .

9. Is polarity of signal correct? (+) to term +4-20 and (-) to

term -4-20 .

10. Is pin jumper for input signal selection (CN4 or CN2) on

the correct pins? See Figure 18*.

11 . If present, remove wires from pumpdown terminals IN &

GND. Did the valve open?

12 . Put a jumper across terminals IN & GND . Did the valve

close?

13 . Remove the jumper from terminals IN & GND and

reconnect the wires .

14 . Remove the pin jumper from CN4 or CN2 . Did the valve

close?

Interface board is functional, test external controller

*Note: CN4 provides 3 levels of input impedence to match external controller outputs . Be sure controller output and interface board

inputs are matched .