Electrical connection – ClimaCool UGW Manual User Manual

Page 21

19

www.climacoolcorp.com

Electrical Connection

The power for all modules is taken from a suitable circuit

breaker/fused disconnect power supply within the main

panel . The electrical service enters the individual modules

through the top into the module’s control panel enclosure .

Proper grounding of the module is mandatory . Before

carrying out any electrical work, confirm that the main

supply is isolated. A typical power wiring is located on page

60 – Power Distribution Drawing . Knockout drawings are

provided . Do not drill into cabinet; shavings can damage

electronic components . The power for all individual modules

shall be in compliance with all local and national codes .

CoolLogic Control System Wiring

A separate 115 volt power supply is required to power the

CoolLogic Master Control Panel . Communication between

the Master Control Panel and chiller modules requires a

simple two-conductor 18 AWG shielded cable rated at 60°C

minimum, daisy chain connection . Control wiring cannot be

installed in the same conduit as line voltage wiring or with

wires that switch highly inductive loads such as contactor

and relay coils. Refer to the Power Distribution schematic

on page 60 of this manual for more information . All wiring

shall be in compliance with all local and national codes .

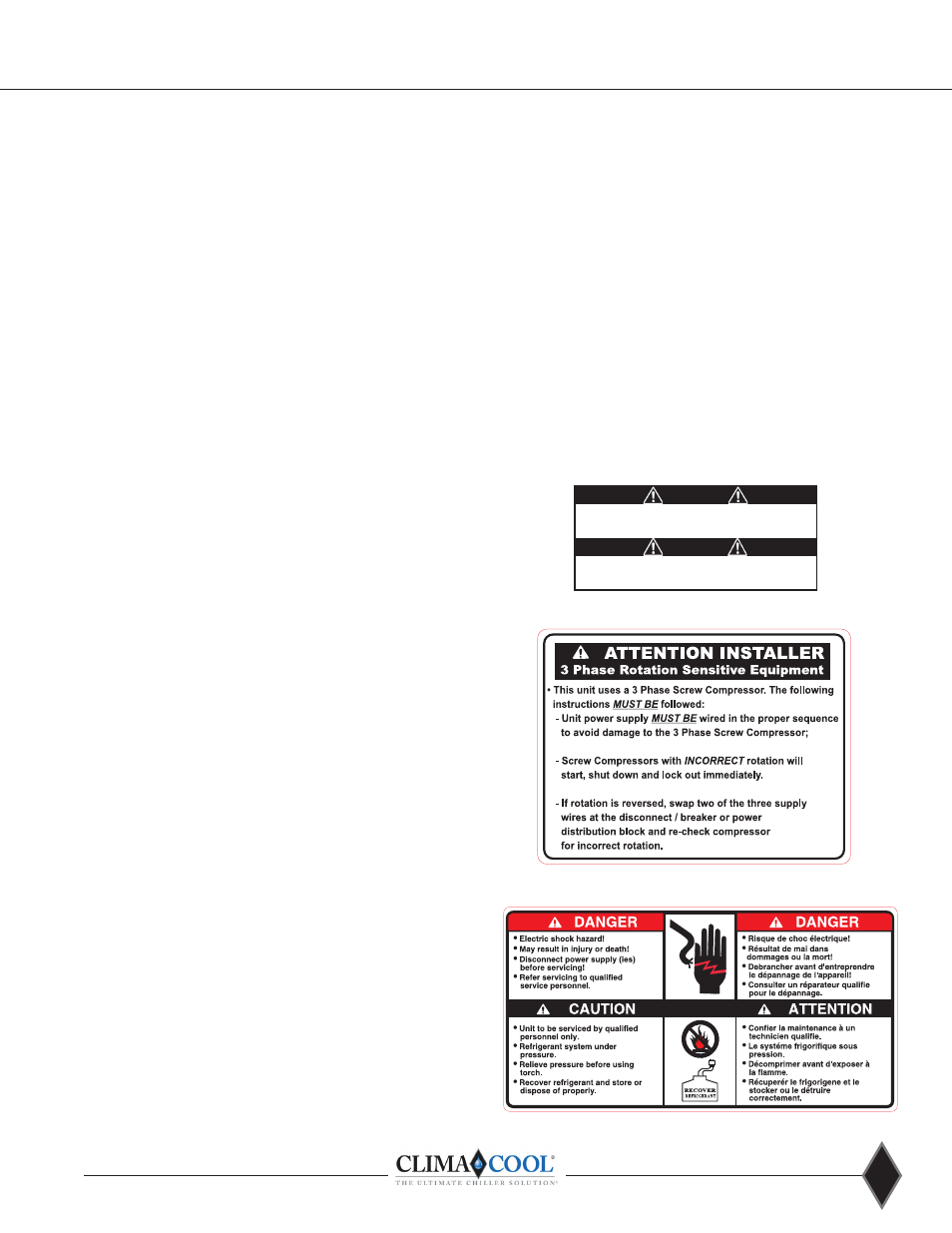

Electrical Phase Sequencing

Proper clockwise rotation for scroll compressor motors

is important to prevent damage to the compressors .

ClimaCool recommends the use of a phase sequence

indicating instrument following the manufactures

directions . An alternative is to “bump test” the compressors

one at a time with pressure gauges attached to the high and

low gauge ports of the compressors to check for proper

rotation . Energize the compressor for a few seconds to

ensure the discharge pressure gauge increases significantly.

If the discharge pressure does not increase, proper

rotation is reversed . Compressor rotation can be reversed

by opening the main electrical disconnect and switching

any two of the main power supply leads feeding that

compressor’s contactor .

Proper Voltage Balance

Occasionally, in three phase circuits, a voltage imbalance

occurs between phases . It is not recommended to operate

equipment when an imbalance greater that 2% occurs . This

causes motors to run at high temperatures and may affect

their longevity . The following example describes how to

calculate the average voltage of the three phases to see if

the imbalance is greater than 2% .

Example: Line 1 = 226v Line 2 = 230v Line 3 = 228v

The average is: (226+230+228) / 3 = 228v

Next, [100(228-226)] / 228 = 0.9%

The voltage imbalance of the three phase circuit is 0 .9% .

This is well under the 2% range .

Voltage/Phase Monitor

Voltage/phase monitors are factory supplied for field

installation with the CoolLogic Master Control Panel . The

voltage/phase monitor helps guard the chiller bank against

voltage fluctuations, phase failure or phase reversal

conditions which could void your warranty . The voltage/

phase monitor has three wires that connect to the main

three phase power chiller bank input . Two low voltage

control wires are connected to the CoolLogic Master Control

Panel . Do not install control wiring in the same conduit

as line voltage wiring or with wires that switch highly

inductive loads such as contactor and relay coils . Note: It

is mandatory to install one (1) monitor per bank at main

power distribution panel to monitor voltage and phasing of

power to the modules. See Wiring Diagram on page 20.

WARNING!

WARNING! To avoid possible injury or death due to electrical

shock, open the power supply disconnect switch and secure it

in an open position during installation .

CAUTION!

CAUTION! Use only copper conductors for field installed

electrical wiring . Unit terminals are not designed to accept

other types of conductors .