Water piping configuration – ClimaCool UGW Manual User Manual

Page 14

www.climacoolcorp.com

12

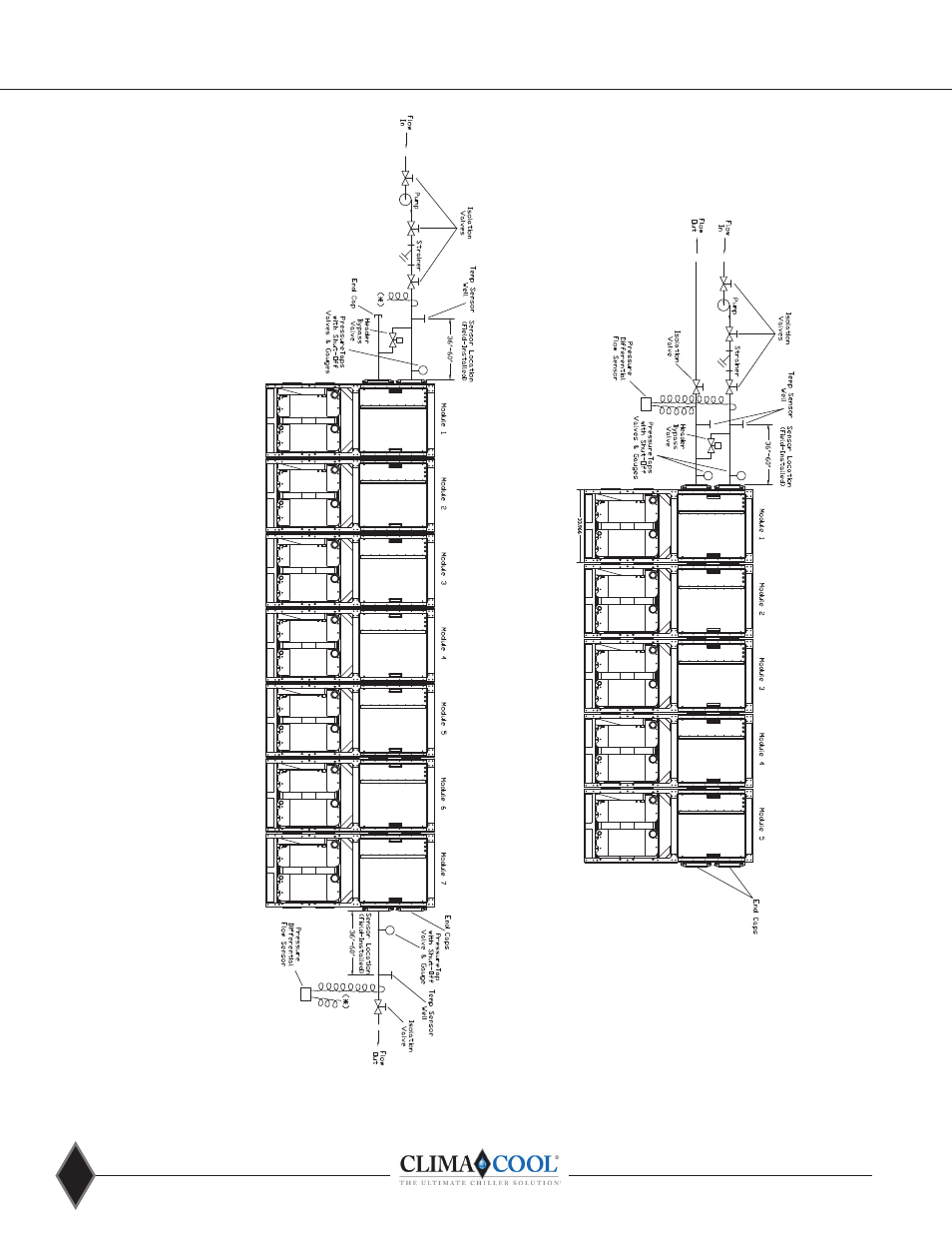

Water Piping Configuration

Notes:

1 .

Figures 9 and 10 are required piping for proper water regulation and distr

ibution through ClimaCool modular chillers

.

2.

Module order and incoming/outgoing water flow as shown in both Figure

9 and 10 can be set up as either a left-to-right or right-to-left configuration.

3.

Evaporator Hydronic Circuit shown. Piping configurations are similar for t

he condeneser water hydronic circuit.

4.

For condenser and chilled water (evaporator) inlet/outlet location dimens

ions, refer to page 6 Module Dimension Data.

5.

A pressure differential flow sensor is a required safety device for ClimaCoo

l modular chillers on the chilled and condenser water circuits.

6 .

A strainer with a minimum of 60 mesh stainless steel screen is a required

safety to protect the brazed plate heat exchangers on both chilled and condenser water sides of the system

.

7.

Maximum water flow rates for both evaporator and condenser water hea

der systems in one bank of modules is 2,400 gpm

.

8 . Bypass is

mandatory

for systems utilizing motorized valves

.

9 . Header bypass valve may be installed at either end of bank

.

10. For over seven (7) modules, please consult the factory.

Figure 9 - Field Piping Direct Return

Figure 10 - Field Piping Reverse Return