Pre-startup – ClimaCool UGW Manual User Manual

Page 23

21

www.climacoolcorp.com

Pre-Startup

All startups must be performed by ClimaCool factory

trained personnel. Prior to chiller startup, there are certain

essential checks which must be completed . Failure to carry

out these checks could result in damage to the chiller

voiding the modules warranty .

Electrical

It is imperative to turn off the main electrical power supply

and follow proper lock-out/tag-out procedures prior to

servicing any of the chiller’s electrical components . The

following procedures can be performed only after the

electrical power is confirmed to be off:

1. The installation must be inspected and approved by the

respective agent and be in compliance with all local and

national electrical codes .

2. Check and tighten all electrical terminal connections on

each module as required . Utilize any lock-out/tag-out

procedures required for your project location when

performing this operation . If no procedure exists, take

all precautions necessary to prevent the power from

being turned on . A systematic tightening of all terminals

inside the electrical control panel on each module

should be carried out . This will include the compressor

motor terminals, which would require removal of the

compressor terminal cover . Check connections at each

safety and every termination in the panel .

3. Verify that a separate 115 volt power supply is used to

power the CoolLogic Control System . Field connections

are simplified requiring only a two conductor shielded

cable daisy chain from the Master Control Panel to the

modules . These control wires should be two-conductor

shielded having #18 AWG minimum up to 50 feet, #16

AWG minimum up to 100 feet, rated at 60°C minimum .

All field wiring must be identified (tagged). Refer to

Power Distribution Drawing on page 60 .

4. All field connections should be checked for tightness.

5. Check all fuses for proper sizing as indicated on the

chiller data plate and/or the electrical diagram on the

inside door of the electrical panel .

6. Verify proper operation of the mandatory field installed

pressure differential flow sensor or switch.

7. On 208/230v units, confirm tranformers are properly

tapped for the measured incoming power supply .

8. Verify proper installation of the mandatory factory

provided, field installed voltage/phase monitor.

Refrigeration

1. Refrigerant piping and components should be inspected

for damage .

2. Place refrigerant gauges on the discharge and suction

access ports of each refrigerant circuit to ensure a

refrigerant charge is present . Leave the gauges on for

compressor rotation check .

3. Confirm the settings on all pressure sensors.

Water System

1. Confirm that leak testing has been carried out.

2. Confirm that the system is clean.

3. Confirm that necessary water treatment systems are

in place with both the evaporator and condenser

water systems .

4. Confirm that both the chilled water and condenser

water circulating pumps are operational and water is

flowing through both exchangers.

5. Shut the entering water valve and blow out some

water to check for particles or coloration from

suspended particles. Record the pressure differential

across the chiller and condenser heat exchangers,

measured at the pete’s ports at each module .

6. Confirm correct water flow rates through the

condenser and evaporator . Acquire the design

parameters for the chiller bank from the ClimaCool

Selection Program data (available from the local

representative). Compare the measured differential

pressures from step 5 above with the predicted flow

rates to ensure proper correlation to the flow results.

7. Verify proper installation of the mandatory factory

provided, field installed temperature sensors and

wells (sensor should be fully inserted in the well) and

verify calibration of sensors read through the CoolLogic

Control System .

8. Confirm installation of mandatory field installed

condenser and chilled water strainers with a

minimum of 60 mesh screens.

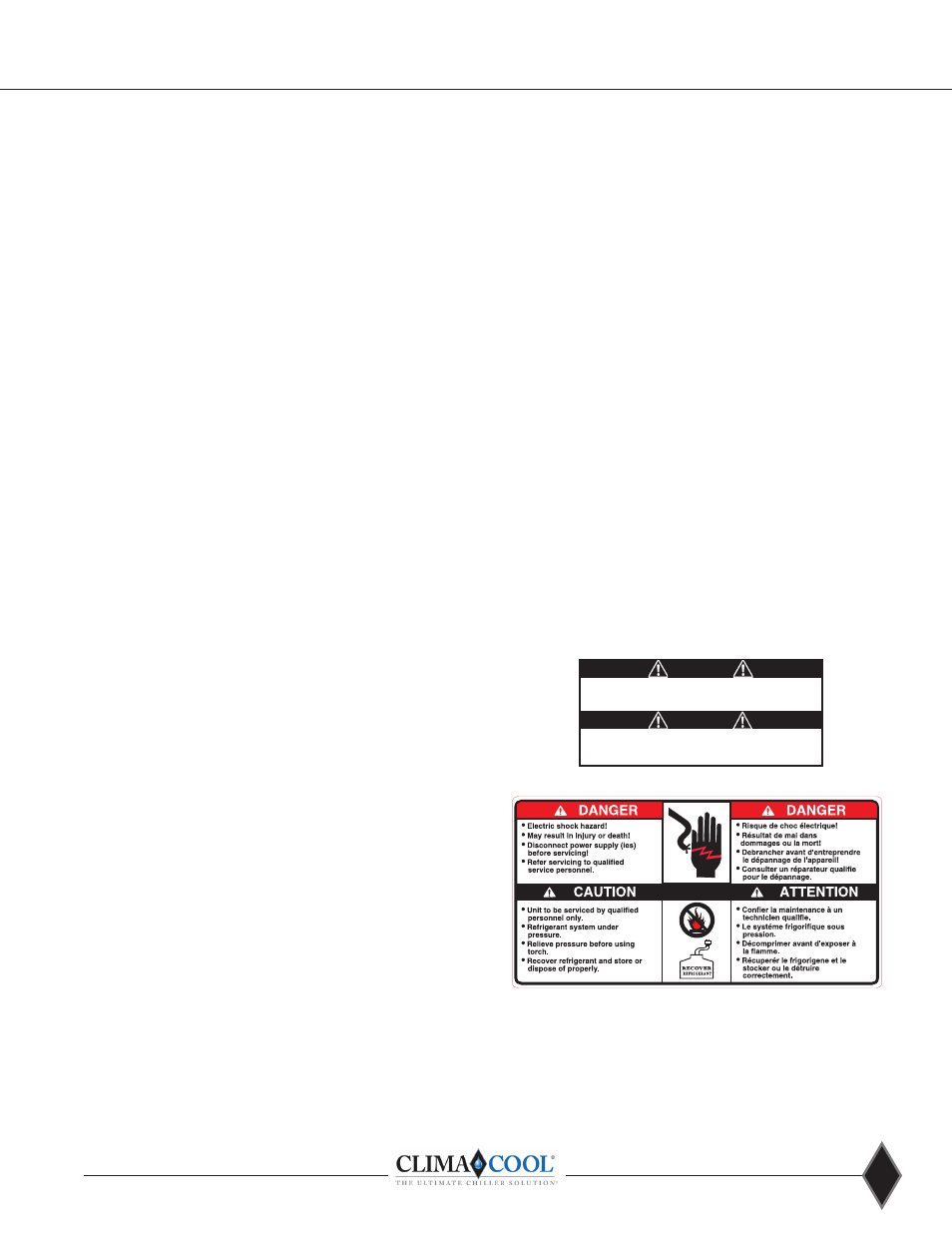

WARNING!

WARNING! To avoid possible injury or death due to electrical

shock, open the power supply disconnect switch and secure it

in an open position during installation .

CAUTION!

CAUTION! Use only copper conductors for field installed

electrical wiring . Unit terminals are not designed to accept

other types of conductors .