Stainless steel strainer option, Troubleshooting for atf package, Auxiliary contacts – ClimaCool UGW Manual User Manual

Page 59: Water resistance

57

www.climacoolcorp.com

When the differential set point is reached, both the audible

and visual alarms will be triggered . It will remain engaged

until both the alarm condition is corrected and the

alarm-reset button is pressed (if the alarm-reset button is

pressed but the differential pressure is beyond the set point,

the alarms will re-engage immediately) . After the strainer

is cleaned and put back in service, the differential pressure

should return to 1 psi .

Auxiliary Contacts

The PDA option is equipped with a remote alarm feature .

The remote alarm contacts are located at the two black and

red banana clip posts (See Figure 25). The alarm can be set

up in one of two ways:

1. A remote alarm signal of 12 VDC can be sent to a central

monitoring station or

2. A set of auxiliary contacts will indicate a “closed”

condition when the alarm activates. (Locate the

Auxiliary Contact Schematic inside the PDA box by

removing the four screws on the cover plate) .

Water Resistance

The Pressure Differential Alarm Controller is water-resistant,

but not water proof . Do not install below ground level

where the box can be submerged in water . Do not remove

the cover plate from the PDA controller . Keep the cover

tightly sealed on the module during normal operation .

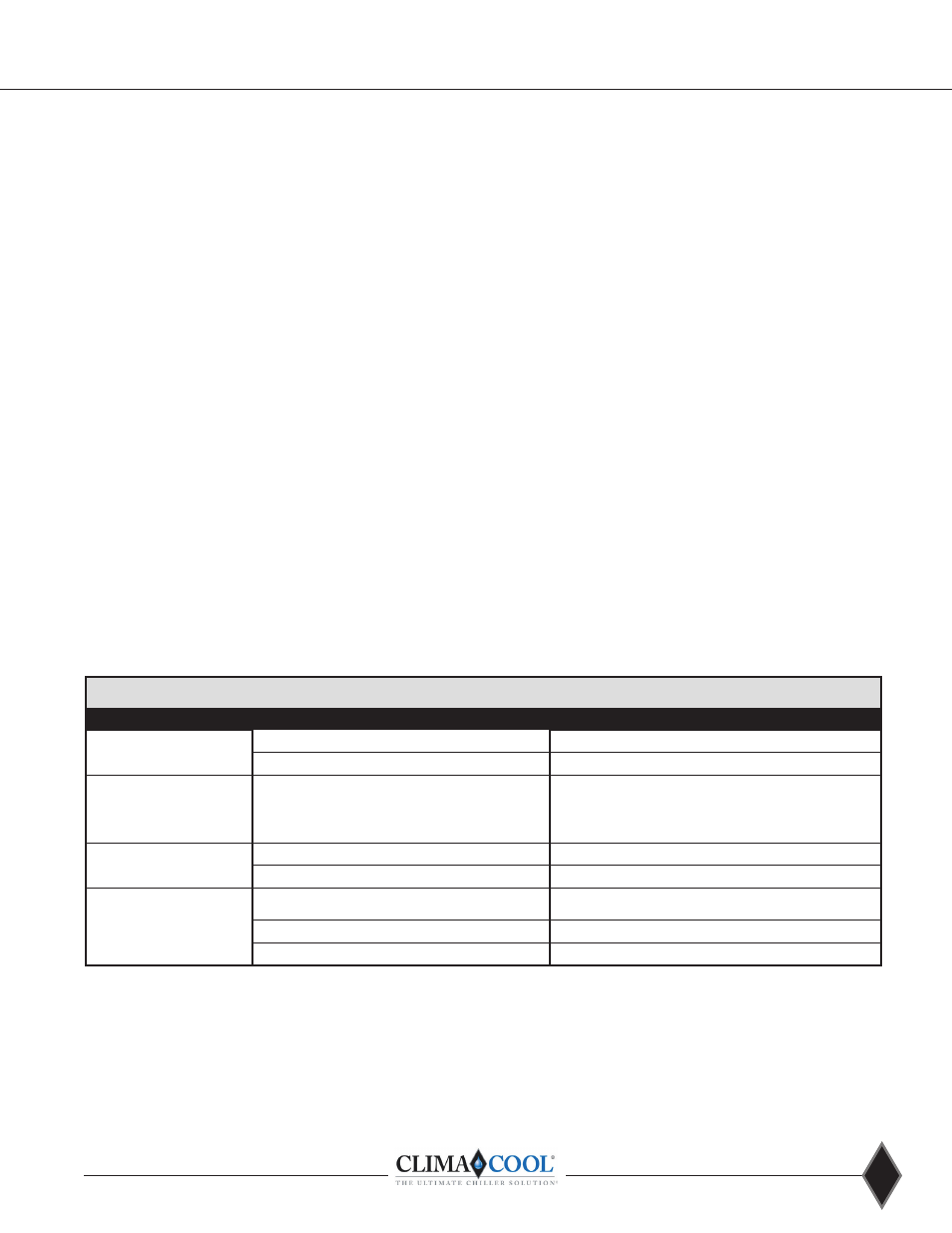

Problem

• Seals damaged or worn out

• Install repair kit

• Valve is not stopping at proper closed position

• Adjust limit switches

Valve stem leaks

• Worn stem seals

•

On metal valves: tighten stem packing nut 1/2 turn.

CAUTION! Over tightening stem nut could cause drag on

motor and trip internal circuit breaker. May require repair kit

or new valve.

• Loose body bolts or excessive operation pressure

• Check bolts and observe recommended pressure ratings

• Defective seals

• Install repair kits or new valve

• Swollen seals or product buildup in valve chamber

• Check valve for compatibility with product, may require valve

cleaning or new valve

• Valve bolts too tight

• Loosen bolts slightly

• Stem nut too tight

• Loosen stem nut slightly

Troubleshooting for ATF Package

Solution

Valve is leaking past ball

Valve hard to turn

Valve body leaks

Table 3

Stainless Steel Strainer Option