Water piping, Temperature sensor and wells, Pressure differential flow sensor – ClimaCool UGW Manual User Manual

Page 12: Pressure taps, Water isolation valves, Strainers – minimum 60 mesh screen required, Chiller/heater system water header bypass, Figure 7 - reverse return, Figure 6 - direct return

www.climacoolcorp.com

10

Water Piping

As with any water system, it is important that the system

be clean . The pipe work installer must remove weld scale,

rust and contamination during pipe work fabrication .

The system water piping must be flushed thoroughly

with recommended alkaline flush or other chemicals that

are compatible with 316 stainless steel, prior to making

connections to the ClimaCool chiller . There are certain

necessary components that should always be installed

in both the chilled water and condenser water systems .

(See Water Piping Configuration Figures 9 and 10 on page

12). Piping configurations on multiple modules may also

be found on page 12 . All water piping must be installed in

accordance with applicable codes and standards .

Temperature Sensor and Wells

ClimaCool provides four (4) temperature sensors and wells

with each chiller system configured by the CoolLogic Control

System. They must be field installed 36” - 60” away from

the bank and before the strainer on the chilled water inlet,

chilled water outlet, condenser water inlet and condenser

water outlet (See Water Piping Configuration – page 12).

Note: Sensors must be fully inserted into the well to obtain

proper readings.

Pressure Differential Flow Sensor

It is imperative that minimum and maximum water flow

rates, as defined in the Physical Data tables on page 5, are

not exceeded . To prevent operation of the chiller without

sufficient water flow to the evaporator and condenser, it

is required to install pressure differential flow sensors in

both the chilled and condenser water circuits . Place one

on each side, downstream of the strainers on the inlet and

outlet of a straight pipe, as close to the module as possible .

Do not put in an elbow on the outlet. (See Water Piping

Configuration – page 12). Note: Evaporator and condenser

sides both require sensors of equal pressure ranges.

Pressure Taps

The installing contractor must provide access ports for

connecting both the pressure differential flow sensor and

pressure gauges for both the condenser and chilled water

systems . A ¼” pressure tap is required on the inlet and the

outlet of both water systems for a total of eight (8) taps. If a

port is shared by the pressure differential flow sensor and the

pressure gauge, it will require four (4) ½” taps. (See Water

Piping Configuration – page 12).

Water Isolation Valves

It is recommended to provide bank water isolation valves

for proper isolation and maintenance of the chiller, pump

and strainer (See Water Piping Configuration – page 12).

Strainers – Minimum 60 Mesh Screen Required

ClimaCool chillers utilize brazed plate heat exchangers

which are extremely sensitive to debris . Therefore, it is

mandatory that all condenser and chilled water systems

include a strainer with a minimum of 60 mesh screen for

proper filtration. The strainers must be installed as shown in

the Water Piping Configuration on page 12 and be in place at

all times when the chiller(s) is/are in operation.

ClimaCool’s warranty does not cover and does not apply to

products which have defects or damages due to freezing

of the water supply, an inadequate or interrupted water

supply, corrosives or abrasives in the water supply, or

improper or inadequate filtration or treatment of the

water supply.

Chiller/Heater System Water Header Bypass

A bypass is required for any chilled water/evaporator, hot

water/condenser (heating load) and source water side

(geothermal, cooling tower or closed circuit cooler) with

variable pumping . The bypass must be piped in such a way

that the temperature and differential pressure sensors are

still sensing active flow. See Water Piping Configuration

Figures 9 and 10 on page 12 . The purpose of the chiller/

heater system bypass is to prevent deadheading of the

pumps when all of the internal unit valves go closed as well

as allow temperature and differential pressure sensors

to sense active flow. The bypass should be sized for an

absolute minimum of one module’s worth of design flow.

(Please refer to selection submittals for design flow rates).

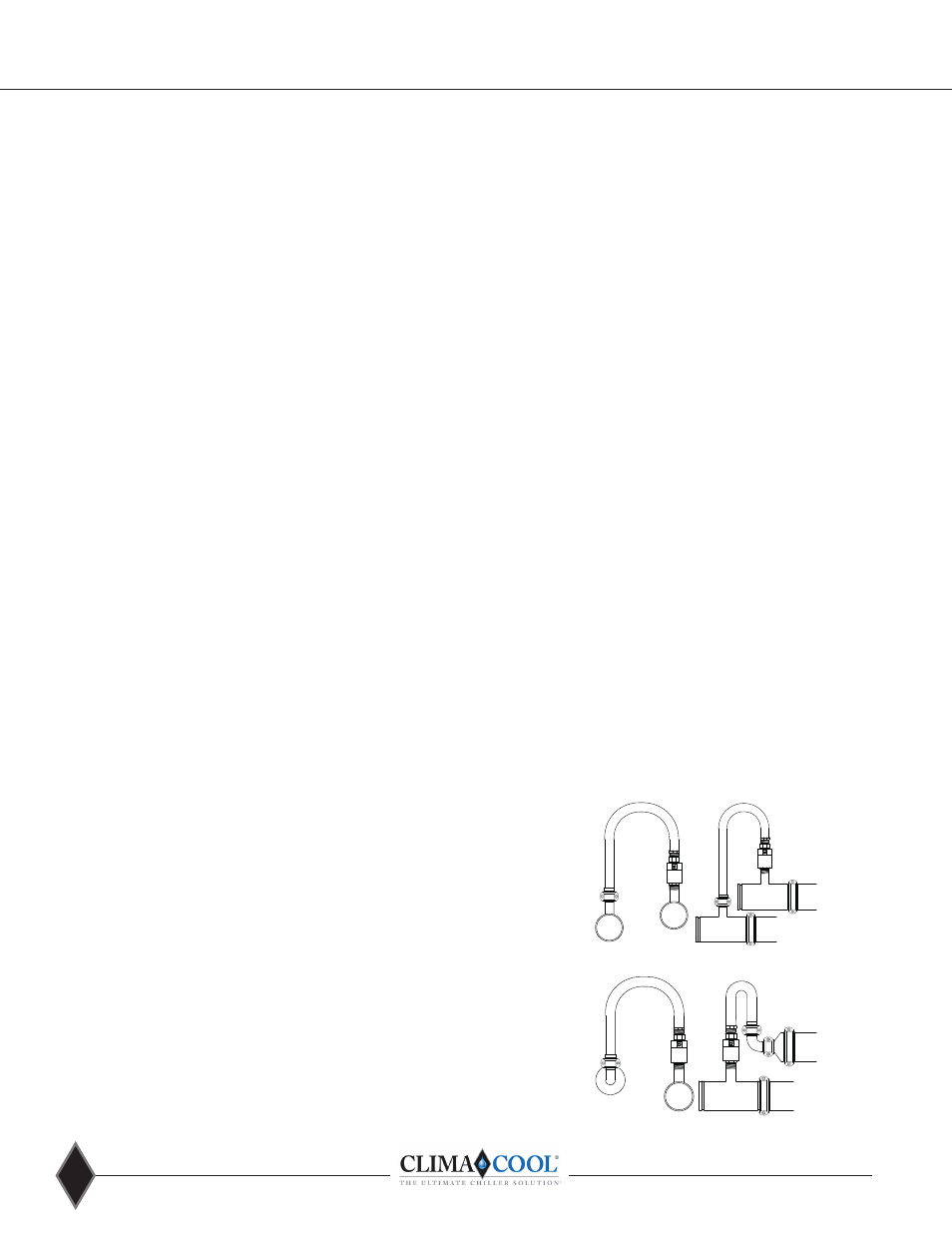

HEADER BYPASS

REVERSE RETURN

No.10

2" 90°

No.50

Reducer

6 x 2

Module

Header

No. 29 Reducing Tee

w/Thd. Branch

6 x 6 x 2

Module

Header

SIDE VIEW

6"

Grooved

C

ou

pl

in

g

6"

Grooved

C

ou

pl

in

g

2"

Gro

oved

Co

up

lin

g

Hose Kit

2"

Grooved

Coupling

2" Belimo

Ball Valve &

Actuator

No. 29 Reducing Tee

w/Thd. Branch

6 x 6 x 2

END VIEW

No.10

2" 90°

Elbow

No.50 Reducer

6 x 2

Hose Kit

2" Belimo

Ball Valve &

Actuator

2"

Grooved

Coupling

HEADER BYPASS

REVERSE RETURN

No.10

2" 90°

No.50

Reducer

6 x 2

Module

Header

No. 29 Reducing Tee

w/Thd. Branch

6 x 6 x 2

Module

Header

SIDE VIEW

6"

Grooved

C

ou

pl

in

g

6"

Grooved

C

ou

pl

in

g

2"

Gro

oved

Co

up

lin

g

Hose Kit

2"

Grooved

Coupling

2" Belimo

Ball Valve &

Actuator

No. 29 Reducing Tee

w/Thd. Branch

6 x 6 x 2

END VIEW

No.10

2" 90°

Elbow

No.50 Reducer

6 x 2

Hose Kit

2" Belimo

Ball Valve &

Actuator

2"

Grooved

Coupling

Figure 7 - Reverse Return

No. 25 Grooved Branch

6 x 6 x 2

Module

Header

6"

Grooved

C

ou

pl

in

g

HEADER BYPASS

DIRECT RETURN &

SIMULTANEOUS HTG & CLG

No. 29 Reducing Tee

w/Thd. Branch

6 x 6 x 2

Module

Header

6"

Grooved

C

ou

pl

in

g

SIDE VIEW

No. 25 Grooved Branch

6 x 6 x 2

No. 29 Reducing Tee

w/Thd. Branch

6 x 6 x 2

END VIEW

Hose Kit

2" Belimo

Ball Valve &

Actuator

2"

Grooved

Coupling

2" Belimo

Ball Valve &

Actuator

Hose Kit

2"

Grooved

Coupling

No. 25 Grooved Branch

6 x 6 x 2

Module

Header

6"

Grooved

C

ou

pl

in

g

HEADER BYPASS

DIRECT RETURN &

SIMULTANEOUS HTG & CLG

No. 29 Reducing Tee

w/Thd. Branch

6 x 6 x 2

Module

Header

6"

Grooved

C

ou

pl

in

g

SIDE VIEW

No. 25 Grooved Branch

6 x 6 x 2

No. 29 Reducing Tee

w/Thd. Branch

6 x 6 x 2

END VIEW

Hose Kit

2" Belimo

Ball Valve &

Actuator

2"

Grooved

Coupling

2" Belimo

Ball Valve &

Actuator

Hose Kit

2"

Grooved

Coupling

Figure 6 - Direct Return