Stainless steel strainer option, What causes water hammer, What can water hammer do – ClimaCool UGW Manual User Manual

Page 57: What prevents water hammer, Automatic timer flush (atf) package option, System components, Valve specifications (see figure 24)

55

www.climacoolcorp.com

Stainless Steel Strainer Option

What Causes Water Hammer?

Any action that can cause a rapid change in the velocity

of the flow can set off a water hammer, such as closing a

downstream valve, pump stoppage, etc . Typically, for

short lengths of pipe (below 500 feet) downstream valves

that are closed within 1/10

th

of a second can generate a

water hammer .

What Can Water Hammer Do?

Pressure spikes from water hammer can raise fluid pressures

to dangerously high values . These pressure spikes can cause

serious damage to valves, pipes, strainers, joints, etc . The

CS strainer is rated to an absolute maximum pressure of 150

psi for bolted lid models, and 125 psi for clamp lid modes .

A water hammer pressure spike that raises the pressure

higher than the maximum rated pressure may result in

strainer damage, voiding the manufacturer’s warranty .

What Prevents Water Hammer?

There are certain precautions that can be taken to prevent

or decrease the effect of water hammer. The addition of a

surge tank or accumulator fitted with a suitable pressure

relief valve and strategically located within the water

system may provide adequate protection against the

effects from water hammer. Careful attention should be

given to the design and control strategy for valves and

pumps so their actions do not invite a water hammer .

Automatic Timer Flush (ATF) Package Option

The ATF-EA-1.5 flush valve package provides an automatic

method for flushing away the debris collected in the

strainer’s reservoir . The power supply and timer controls for

the valve package are housed inside the ATF control box .

The ATF controls can be pre-programmed to set the flushing

duration and the time interval between flushes.

System Components

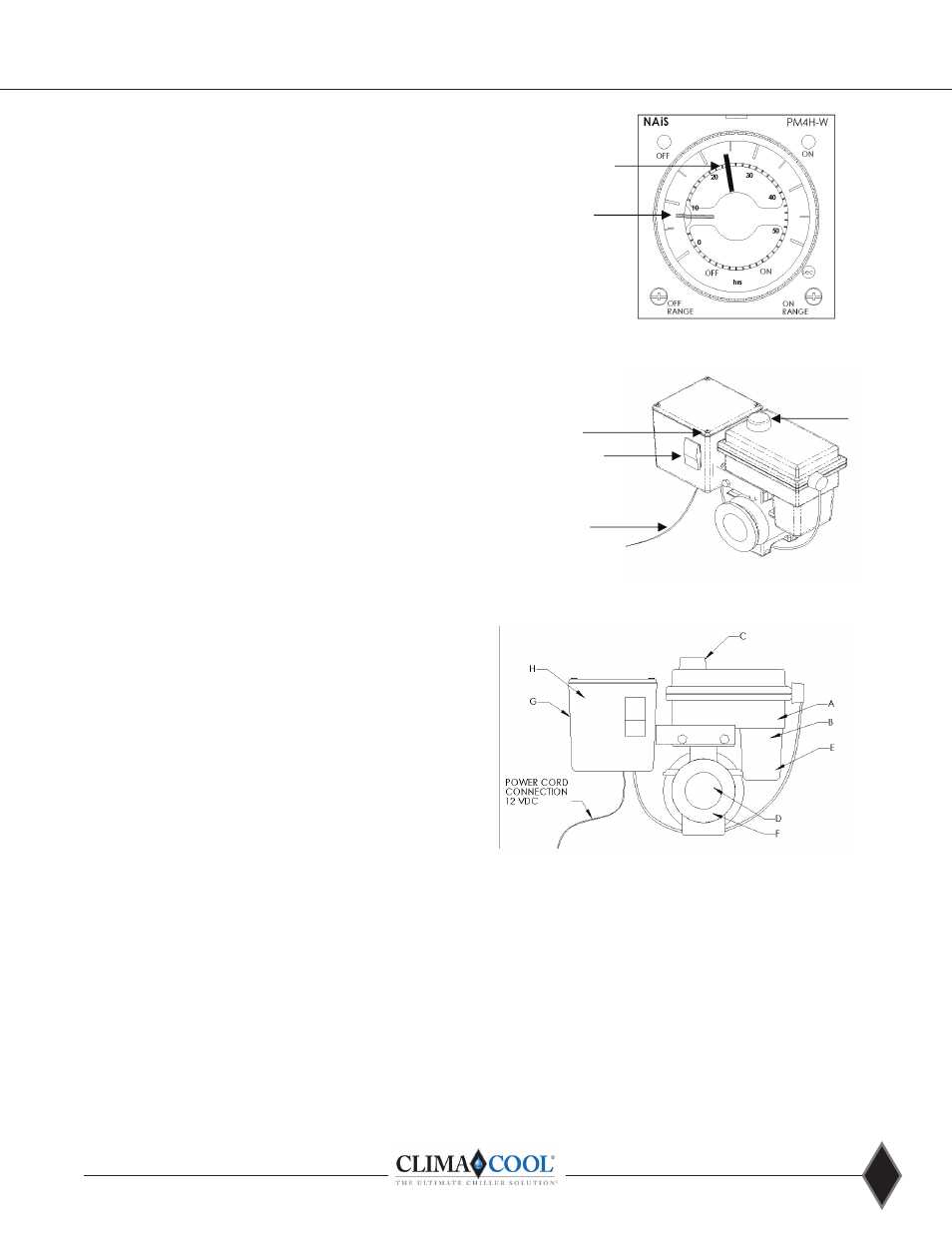

1. Timer based valve controller: (see Figure 22) sets the

flush duration (length of the flush) and the flush interval

(time between flushes).

2. Electric Ball Valve: designed for dirty water use (see

Figures 22 and 23) .

A

GREEN POINTER

INNER RING

(LENGTH OF FLUSH)

(FACTORY SET AT

8-SECONDS)

RED POINTER

OUTER RING

(TIME BETWEEN

FLUSHES)

(FACTORY SET AT

24-HOURS)

Figure 23

B

[email protected] POWER

FROM PDA OR 120V PLUG

IN TRANSFORMER

OPEN/CLOSE

INDICATOR

COVER-PLATE SCREWS

(4) IN CORNERS OF BOX

(TIMER BASED VALVE

CONTROLLER)

CONTROL SWITCH

Figure 24

Valve Specifications (See Figure 24)

A . Water-resistant polypropylene motor case

B . High torque motors with perma-lube gears

C . Open and close indicator

D . Stainless steel ball valve and hardware

E . Auto reset circuit breaker

F . 90

o

bidirectional rotation

G . Controller case

Figure 22