Tool configuration, Test data, Flatness – Climax LM6000 OBS LINEAR/GANTRY MILL User Manual

Page 7: Metal removal rates

Tool Configuration

Tool Configuration

Climax Portable Machine Tools, Inc. 2712 E. Second Street, Newberg, OR 97132 USA Web site: www.cpmt.com

Worldwide Phone: 1.503.538.2185 N. America Toll-Free: 1.800.333.8311 Fax: 1.503.538.7600 E-mail: [email protected]

page 7

Z-Axis Feed Assembly

Manual Feed

47219

Electric Feed Assembly, 120V

53226

with 20 ft (609.6 cm) cables

Electric Feed Assembly, 120V

53227

with 50 ft (1524.0 cm) cables

Electric Feed Assembly, 120V

53228

with 100 ft (3048.0 cm) cables

Electric Feed Assembly, 230V with 20 ft

53229*

(609.6 cm) cables (not for use w/ Climax HPU)

Electric Feed Assembly, 230V with 50 ft

53231*

(1524.0 cm) cables (not for use w/ Climax HPU)

Electric Feed Assembly, 230V with 100 ft

53232*

(3048.0 cm) cables (not for use w/ Climax HPU)

* Order 230V stand-alone controls

6 Stand-Alone Feed Controls

(Not needed if using a Climax Hydraulic Power Unit)

Stand-alone feed control & pendant, 120V

53398

with 20 ft (609.6 cm) cables

Stand-alone feed control & pendant, 120V

53399

with 50 ft (1524.0 cm) cables

Stand-alone feed control & pendant, 120V

53400

with 100 ft (3048.0 cm) cables

Stand-alone feed control & pendant, 230V

53401

with 20 ft (609.6 cm) cables

Stand-alone feed control & pendant, 230V

53402

with 50 ft (1524.0 cm) cables

Stand-alone feed control & pendant, 230V

53403

with 100 ft (3048.0 cm) cables

7 Risers

1 inch (25.4 mm) riser assembly

46508

2 inch (50.8 mm) riser assembly

46510

4 inch (101.6 mm) riser assembly

53751

6 inch (152.4 mm) riser assembly

53752

8 inch (203.2 mm) riser assembly

53753

8 Milling Head Swivel Attachment

Optional milling head swivel attachment mounts 53620

between milling head & Ram saddle plate,

allowing milling head to rotate 360º.

Lockable in any position. Please call for details.

9 Digital Read Out

2-Axis Digital Read Out with Swivel Mount

53353

3-Axis Digital Read Out with Swivel Mount

53355

Z-Axis Digital Scale

51863

X-Axis Digital Read Out

(required with DrO)

DRO Scale Tape and Encoder Assembly 48” Bed 53356

DRO Scale Tape and Encoder Assembly 72” Bed 53357

DRO Scale Tape and Encoder Assembly 96” Bed 53358

DRO Scale Tape and Encoder Assembly 120” Bed 53359

DRO Scale Tape and Encoder Assembly 144” Bed 53360

Y-Axis Digital Read Out

(required with DrO)

DRO Scale Tape and Encoder Assembly 24” Ram 53361

DRO Scale Tape and Encoder Assembly 36” Ram 53362

DRO Scale Tape and Encoder Assembly 48” Ram 53363

Z-Axis Digital Read Out

DRO Scale 8” Stroke Milling Head (for 24” rams)

53364

DRO Scale 8” Stroke Milling Head (for 36” rams)

58581

DRO Scale 8” Stroke Milling Head (for 48” rams)

58582

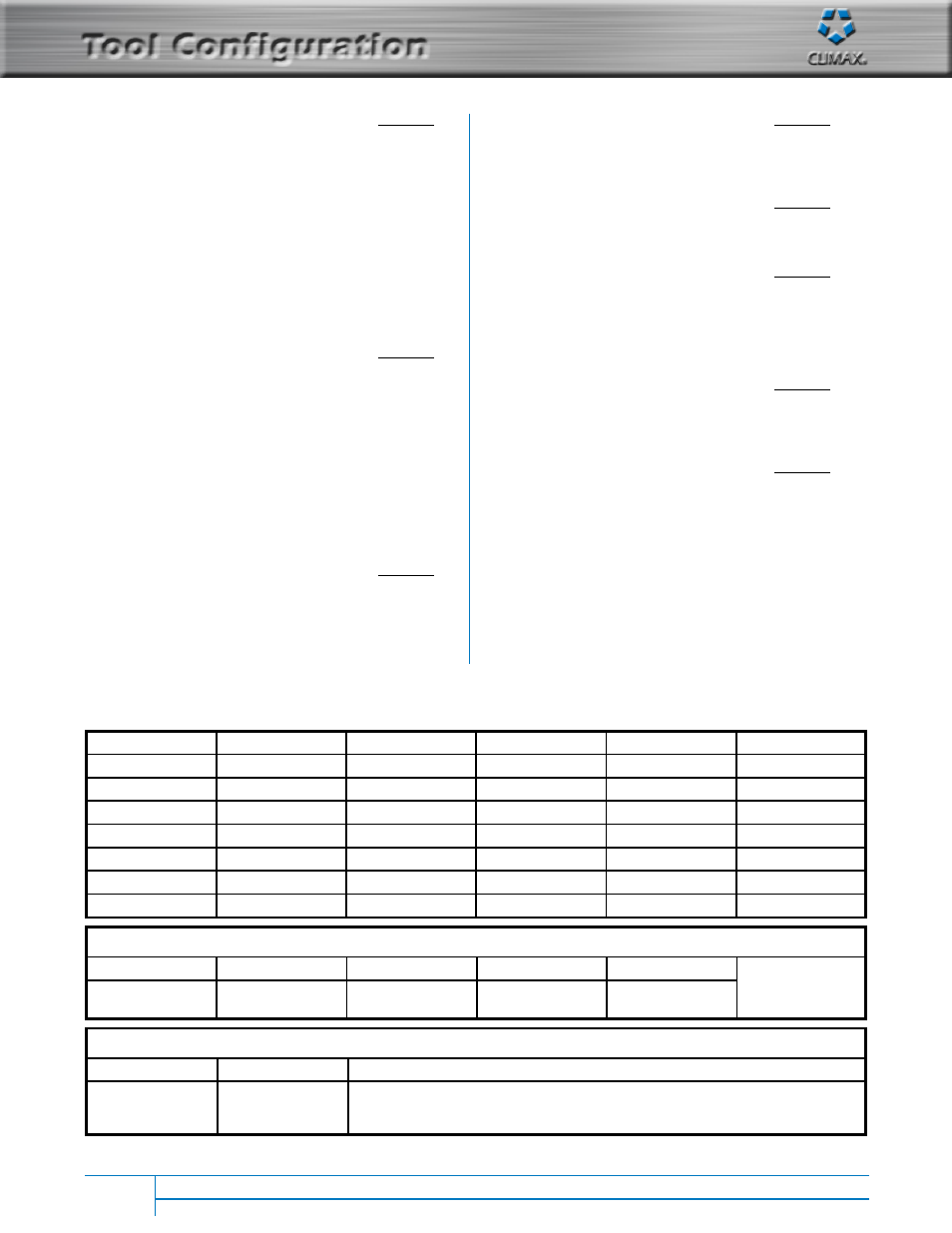

Test Data

All test cuts performed with a 25Hp (18.6 KW) HPU and a 17.9 cu. in. (293.3 cu. cm) hydraulic motor in A-36 steel

Orientation

Cutter Diameter

No. of Inserts

Width of Cut

Depth of Cut

Feed Rate

Vertical (up)

8.0 (203.2)

8

8.0 (203.2)

0.05 (1.27)

5.1 (129.5)/min.

Vertical (up)

8.0 (203.2)

8

7.0 (177.8)

0.10 (2.54)

4.4 (111.8)/min.

Horizontal

8.0 (203.2)

8

5.5 (139.7)

0.10 (2.54)

18.0 (457.2)/min.

Horizontal

8.0 (203.2)

8

8.0 (203.2)

0.10 (2.54)

10.0 (254.0)/min.

Horizontal

5.0 (127.0)

6

3.5 (88.9)

0.10 (2.54)

20.0 (508.0)/min.

Horizontal

5.0 (127.0)

6

5.0 (127.0)

0.10 (2.54)

20.0 (508.0)/min.

Horizontal

5.0 (127.0)

6

5.0 (127.0)

0.15 (3.81)

12.0 (304.8)/min.

Flatness

(Machine setup & flatness measurements performed with a Hamar laser)

Cutter Diameter

No. of Inserts

Material

Area

Total Flatness

8.0 (203.2)

8

A-36 Steel Plate

16.0 x 72.0

(406.4 x 1828.8)

0.0036

(0.091)

Metal Removal Rates

Continuous

Intermittent

Metal Removed Per Hour

7.0 cubic inch

(114.8 cubic cm)

per minute

10.0 cubic inch

(163.9 cubic cm)

per minute

420 cubic inches = 119lbs (54.0kg) steel/hour

600 cubic inches = 170lbs (77.1kg) steel/hour