Climax BW3000 AUTOBOREWELDER – PORTABLE BORE WELDING MACHINE User Manual

Bw3000 autoborewelder

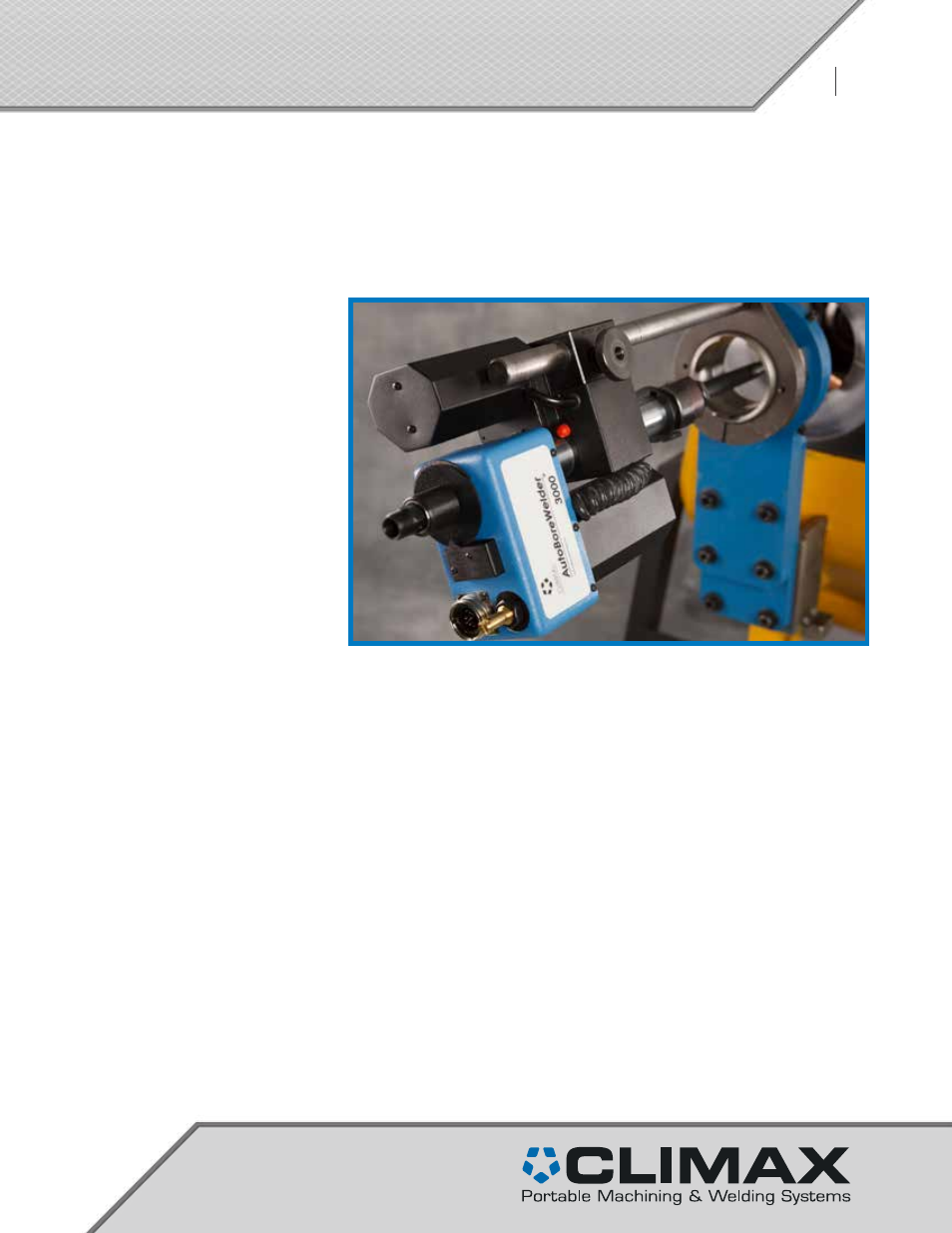

BW3000 AutoBoreWelder

Advanced Automated Step Welding System

for Bore, Flange, and Valve repair.

The Climax BW3000 AutoBoreWelder is an

automated step welding system that provides

a new degree of welding performance and

precision. Weld time is dramatically reduced

while producing precise, uniform, high quality

welds as compared to hand welding techniques.

Unmatched Weld Quality and Precision

• Provides complete weld coverage at the start

and finish of the bore

• Reaches up to 5 feet (152.4 cm) into the bore.

Using torch extension support, can extend

upward using extended reach torch options.

• Lays up to 5 lbs (2.27 kg) of metal per hour.

• Arc time increases 50 - 100% over hand-

welding, cutting weld time in half.

Built-In Cost Savings

• Precise, uniform welds means less wire is

consumed, reducing cost.

• All configurations come ready for a push-pull

wire feeder which prevents wire buckling and

waste when using low column-strength wire.

• Consistent and uniform weld reduces cutting

tool wear, reducing cutting time by up to 50%.

Single Point PLC-Based Control System Enhances

Operator Safety and Control of Welding Process

• Adjust all welding functions from one central

location.

• Weld operator safety is enhanced by allowing

operator to stand back from the weld as it is

being laid.

• Quickly adjust “step” size and direction, rotation

speed and direction, wire feed rate, arc voltage,

arc interrupt, contractor control, gas purge and

extended utilization of Auto-Skip function.

Flexible and Versatile

• Welds in any orientation: vertical, horizontal, or

inverted.

• Allows alternating of uphill and downhill welds

in a horizontal bore when welding multiple

passes

• Patented “offset head” provides radial

adjustments of the torch while maintaining

proper torch angle in relation to the work

piece.

• Wide range of travel speeds and amperage for

challenging in-field conditions or working with

exotic metals.

• With proper options, can weld with any wire -

stelite, nickel, exotic metals.

• Can be configured to perform clad overlay with

nickel alloys, bronze, and exotic metals.

• Four operating modes available: Auto-Skip,

Pie, Carriage Return, and Contiuous Weld.

• Patented step process outperforms spiral

welding by providing complete weld coverage

with infinitely adjustable step, allowing bead

placement from 0.40 - 0.220 inches (1.0 - 5.6 mm).

• Auto-skip feature allows “weld only” or “skip

only” areas to be designated.

• Allows rapid completion of work on out-of-

round bores, bores with keyways.

• Precisely welds conical valve seats.

One Setup for Welding & Boring

• Climax BoreWelder Interface Kit simplifies the

boring & welding setup process.

• Quickly attach the BW3000 AutoBoreWelder

directly to the Climax BB3000, BB4500 or

BB5000 Boring Machine mounting fixtures.

• Interface kit makes it easy to switch between

bore welding and line boring without losing

bearing alignment.

• Interface kit ensures perfect alignment for both

welding and machining.

• One setup for both welding and boring saves

time and gets the job done quickly.

Weld & Bore at the Same Time

• Weld one section while boring out another,

using multiple bearing mounts.

• Simultaneous operation cuts work time in half!

Rugged, Fitted Protective Case for Easy, Safe

Transport:

• Packaged in heavy-duty, shock-resistant

case for safe, dust and water-proof storage,

convenient organization and easy transport

of the BW3000 AutoBoreWelder and its

components.

• Select from shop-style wire feeder, or

enclosed field-style wire feeder in shock-

resistent waterproof case.

2013

BW3

11