Climax FF6000 PORTABLE FLANGE FACER User Manual

Climax Equipment

B r i n g i n g t h e s o l u t i o n t o y o u .

Portable Machine Tools, Inc.

®

F E A T U R E S • S E T U P & O P E R A T I O N

C O M P O N E N T S & A C C E S S O R I E S • T E C H N I C A L D A T A

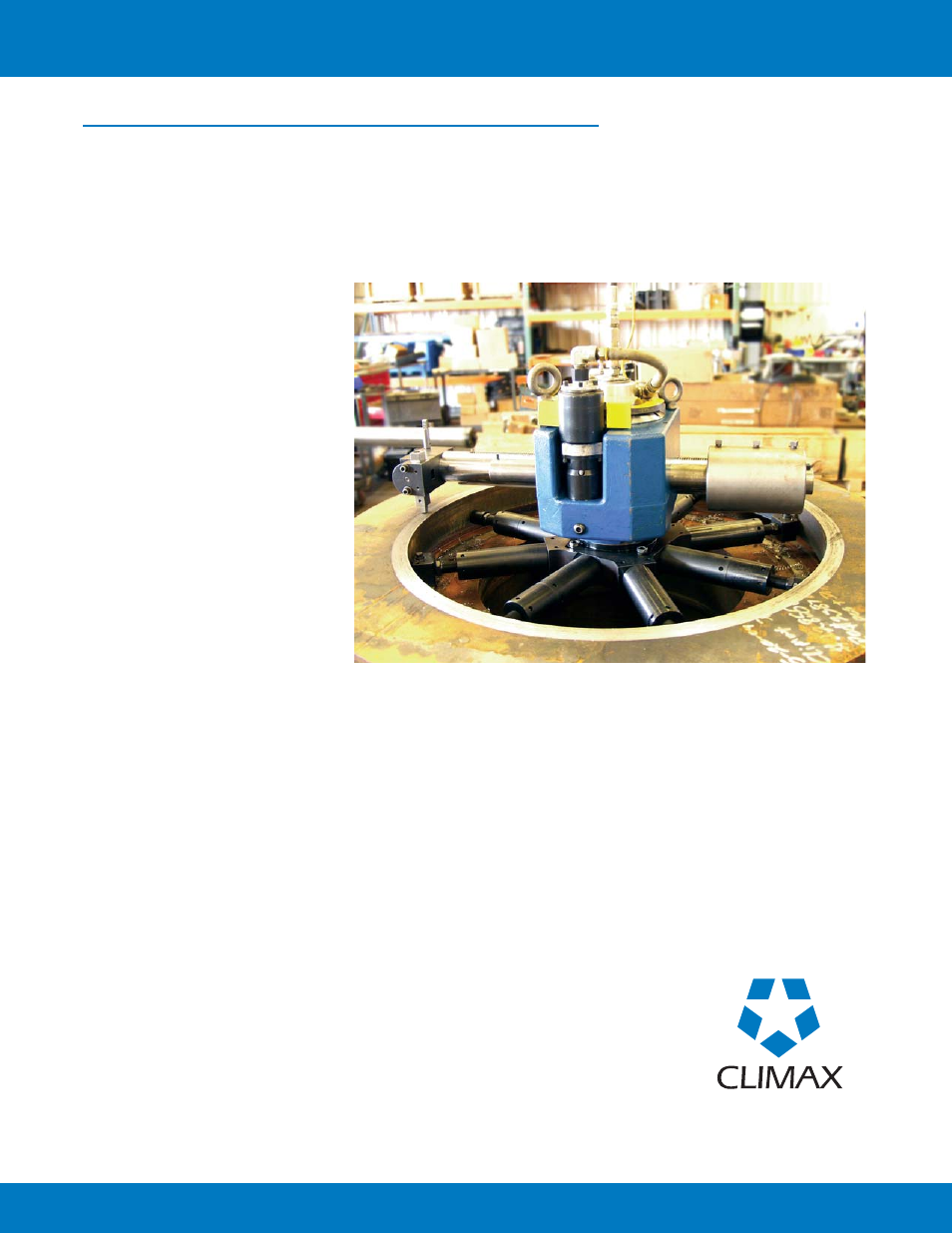

FF6000 PORTABLE FLANGE FACER

Cut your dismantling & downtime costs by re-facing flanges and

repairing seal & bearing fits at the work site

This flange facer will substantially

reduce your costs and maintenance

downtime by allowing you to quickly

repair your flanges, seals, and bearing

fits in place without resorting to costly

disassembly and transportation to a

machine shop. This versatile on-site

flange facing machine will also help

to eliminate expensive and time-

consuming recertification procedures

which may be required when critical

valves and flanges are removed for

repair and then re-installed. The job

can be done quickly to get back in

operation with minimum downtime.

An experienced operator can usually

mount the machine in the flange

bore, align it, and start cutting in 30

minutes.

Solid

Single plane chuck provides rigid

•

clamping in the bore.

3 inch (76 mm) diameter turning

•

bar ensures a rigid tool platform,

even at maximum extension.

A combination of precision ball

•

bearings and heavy-duty Timken

Tapered roller bearings for smooth,

chatter-free machining

Effective

• 9.73:1 gear reduction provides 550

ft•lbs (798 N•m) of torque at the

cutter to remove metal fast.

• Radial feed is 0.003 - 0.032 inch

(0.076 - 0.813 mm) per revolution,

infinitely variable, reversible, rack and

pinion system.

• Down feed rates from 0.003 - 0.010

inch (0.076 - 0.0254 mm) per

revolution are provided by the down-

feed actuator system.

• Tool holder accepts 1/2 inch or 12

mm square tool bits.

Versatile

Sealed lubrication allows inverted

•

operation.

Standard tool head swivels 360

•

degrees in either direction to cut

angles, grooves, chamfers, RTJ, and

weld preps. Use the optional Low

Angle tool holder to cut angles less

t

han 45 degrees to the flange face.

Down-feed allows turning flange

•

edges, and dressing inside flange/

pipe joints,

Optional large bore chuck and

•

bar assembly for flanges up to 60

inches (1524 mm) in diameter.

Other options include:

•

-

Grinding attachment

-

Back facing attachment

-

Low-angle tool holder