Climax FF1000 FLANGE FACER User Manual

Ff1000 flange facer

ff1000 flange facer

easy OD-mount flange facer for repairs of flanges

2 to 12 inches (50.8 to 304.8 mm) in Diameter.

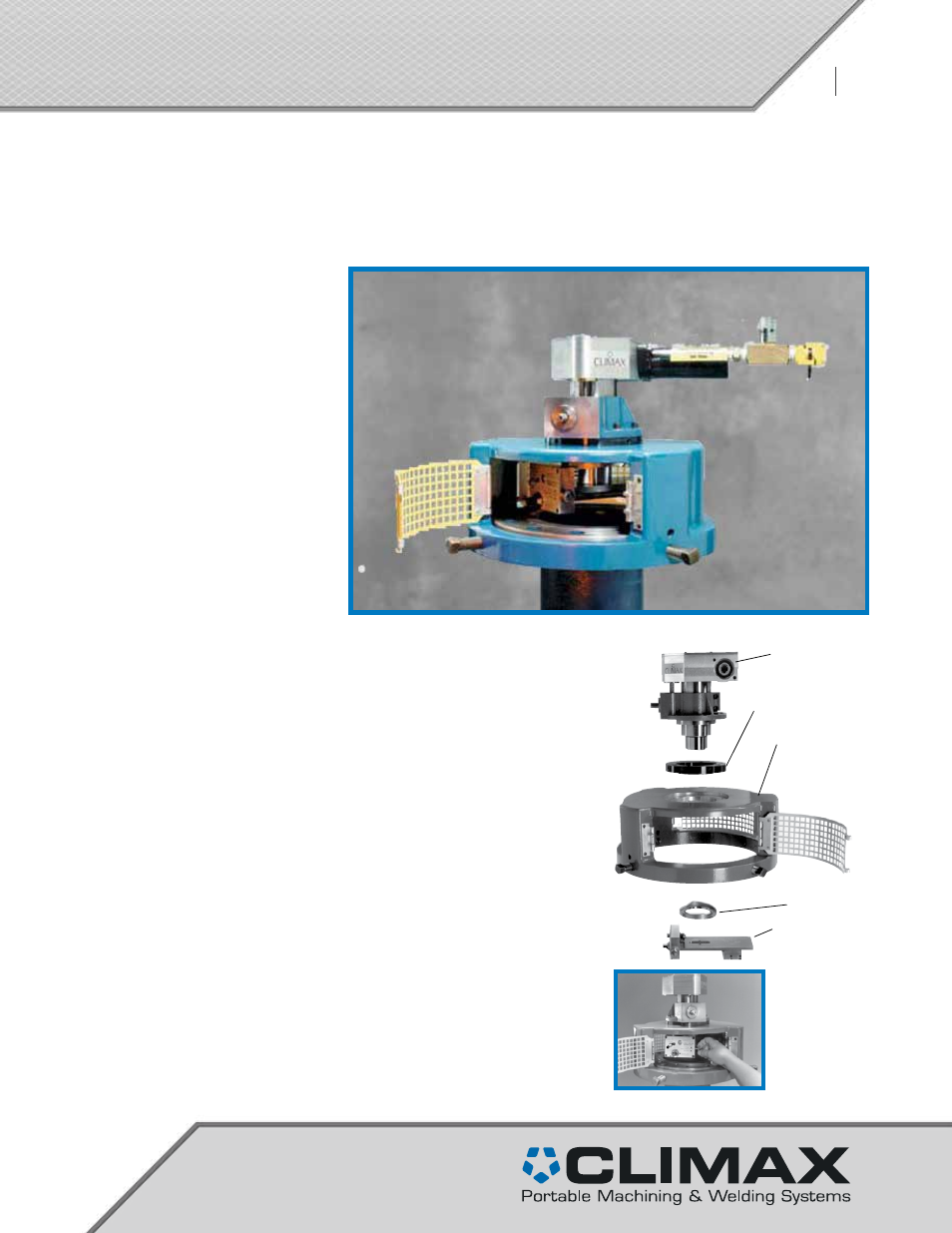

The Model FF1000 Portable Flange Facer

comes complete with all the components

you need to get started. It consists of a

mounting bell, a power module, and a flange

facing module. A 115V power vertical feed

module is offered as an option. Individual

components and accessories are available

for replacement or when required for some

applications. See the Components page for

the package that's right for you.

The Climax FF1000 Flange Facer

• Sets up and operates easily.

• Cuts O-ring grooves.

• Uses standard

3

⁄

8

-inch, square tool bits.

• Includes 1.22 hp (0.91 kW) pneumatic

motor.

Two Mounting Bell Sizes

• 8 inch module mounts on flanges 4 to 8

inches (101.6-203.2 mm) in diameter.

• 12 inch module mounts on flanges 8

to 12 inches (203.2 to 304.8 mm) in

diameter.

Two Power Modules

• Use with either mounting bell.

Variable radial feed rate.Manual depth

adjustment / longitudinal feed.

• 100 rpm with a 15:1 gear reduction,

1-inch (25.4 mm) stroke, 105 ft•lb

(142.7 N•m) of torque.

• 200 rpm with a 7.5:1 gear reduction,

1-inch (25.4 mm) stroke, 52.5 ft•lb

(71.4 N•m) of torque

Optional Power Feed Module

• Some applications require a remotely

operated power axial feed. This 115V

unit attaches to the power module.

Axial feed rates are available from 0.04 to

1.6 inches/minute (1.0 to 40.6 mm/min.).

2013

FF1

1

Two Facing Heads:

• 8 inch module faces 0 to 8 inches

(0 to 203.2 mm) in diameter.

• 12 inch module faces 0 to 12 inches

(0 to 304.8 mm) in diameter.

Optional Small Flange Adapter Plate

• Attaches to the bottom of the 8 inch

(203.2 mm) diameter mounting bell

to allow re-facing flanges from 2 to 4

inches (50.8 to 101.6 mm) in diameter.

• Unit comes complete with setup fingers

to accommodate smaller diameter

flanges.

Quick and Easy Setup

• An experienced operator can set up the

FF1000 Portable Flange Facer in less

than half an hour.

• Once you are familiar with the machine,

re-facing 2 to 3 standard flanges per

hour is typical (depending on the

size and type of flanges, access and

general working conditions).

New low-profile

power module

Flange facing

module

New mounting bell

with wider access

windows

Feed cam

New centering/leveling

plate for easier setup

The new,

wider access

windows make

adjustments to

the facing head

gearbox easier

than ever.