Climax LM6200 LINEAR/GANTRY MILL User Manual

Lm6200 milling machine, Axis linear and gantry milling

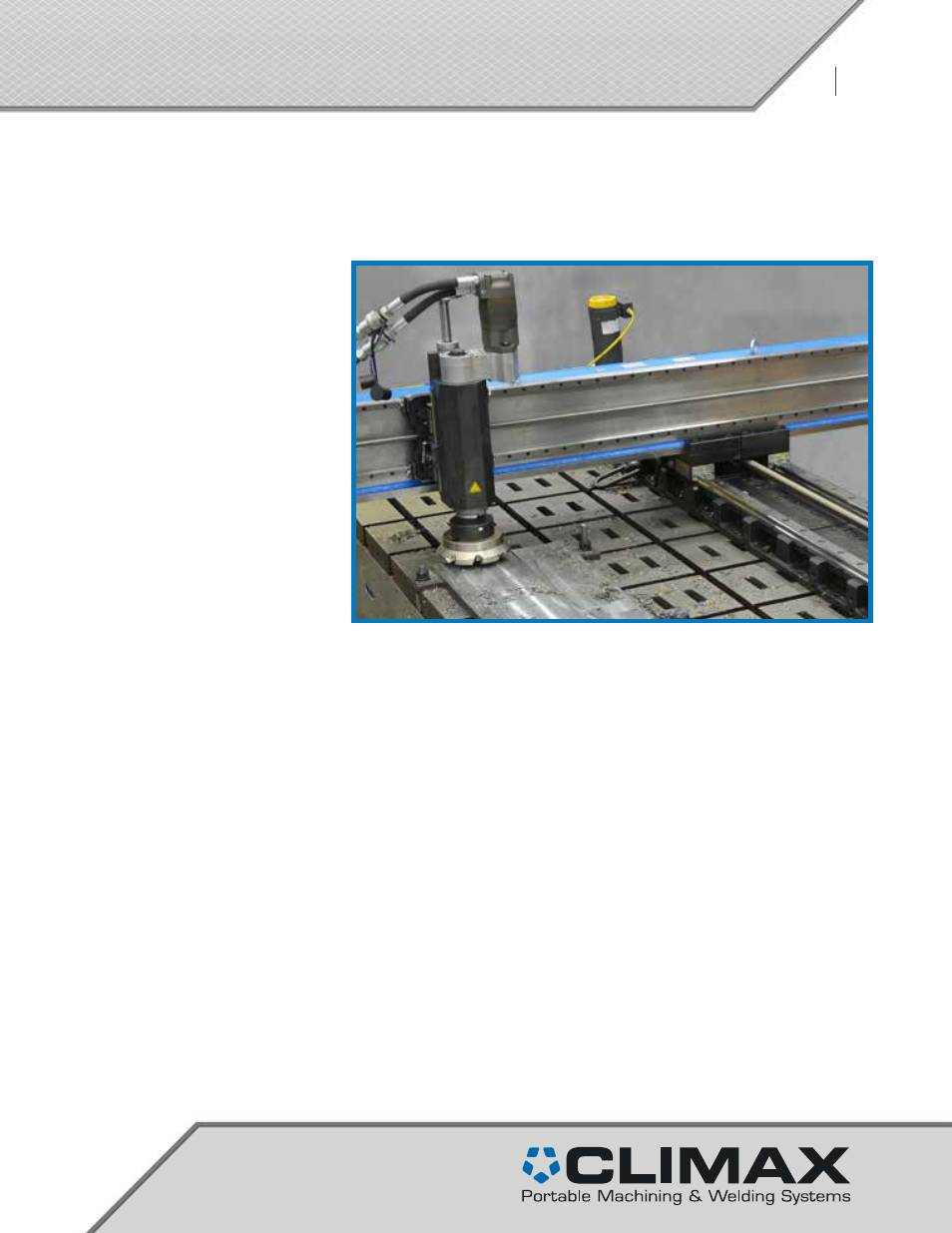

LM6200 MILLING MACHINE

3-Axis Linear and Gantry Milling

The Climax LM6200 Linear/Gantry Milling

Machine revolutionizes both the capabilities

and functionality of portable mills. Four main

features makes this one of the best milling

machines on the market today:

1. Extremely rigid, modular bed design.

2. Powerful, precise machining.

3. Innovative configuration options allow

setup for both Linear AND Gantry

Milling in one machine.

4. Reduced Friction Rail Technology.

Rigid, Modular Design

• Unique modular bed design allows

shorter bed sections to be combined to fit

the length of the work area without losing

rigidity.

• Unique bed length section design provide

superior rigidity across the entire bed

length.

• Connection plates and fasteners

optimized to provide the ultimate in

rigidity, even when bed is extended by 2

or 3 times the original length.

Powerful, Precise Machining

• Features heavy duty spindle design and

a choice of Hydraulic Power Units - a 25

Hp (18.6 kW) HPU allows use of cutter

heads of up to 10 inches (254.0 mm) in

diameter.

• Milling can be done in any axis, with a

milling head that can rotate 360° with an

optional swivel plate for optimal spindle

flexibility. An optional Z-axis slide

assembly can be used for side milling

and to increase the stroke needed for

drilling or extended milling operations.

• Fast, aggressive milling in horizontal,

vertical, or inverted applications.

• Provides reliable, precise milling to meet

tight machining tolerances in both linear

and gantry mill configurations.

Flexible Configuration & Operation

• Innovative design allows machine to be

configured for traditional linear milling, or

simply split the rails lengthwise to

configure for gantry milling!!

• Electric feeds can be mounted on the X,

Y or Z axis.

• Machining capabilities include milling,

drilling and even boring.

Reduced Friction Rail Technology

• Reduced friction rail system allows

extremely smooth, continuous, and non

stick-slip travel.

• Precisely machined and aligned rails with

advanced lubrication make machining

applications smooth and efficient.

• Low friction system reduces maintenance

costs and extends product life.

• Precision ball screws in X, Y and Z- axis

assemblies allow precise location of

milling head.

2014

LM62

05