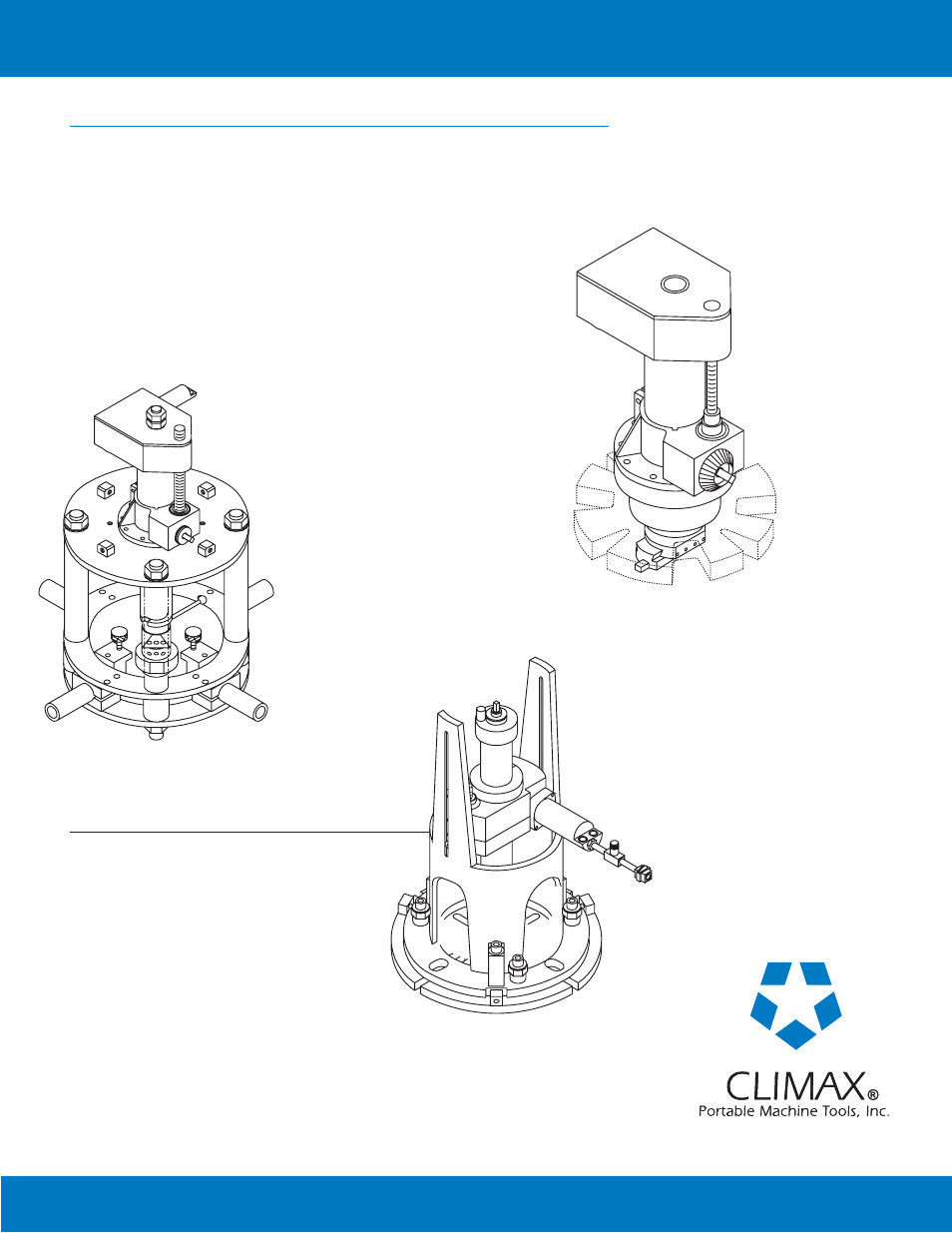

Climax VM8000 GLOBE/CONTROL VALVE REPAIR User Manual

Vm6000, Vm7000, Vm8000

V A L V E R E P A I R M A C H I N E S

B r i n g i n g t h e s o l u t i o n t o y o u .

F E A T U R E S • S E T U P & O P E R A T I O N

C O M P O N E N T S & A C C E S S O R I E S • T E C H N I C A L D A T A

VM6000

Repair in-line valves with 2.5 - 13

inch (63.5 - 330.2 mm) diameter

pressure seal bores

The Model VM6000 Portable Valve Repair

Machine makes on-site repair of a wide

range of valves prac-

tical. The Model

VM6000 is a “generic”

valve repair machine

that mounts on and

bores the

throat area of

any valve the

mounting

fixtures can

attach to.

Remove

the valve

bonnet

assembly to

allow access

to the valve

throat,

machine

a weld

prep groove, apply a weld

buildup as necessary in the eroded area,

and bore out the valve throat to its original

dimensions.

VM7000

Repair a safety valve in

about the same time it

would take to remove the

damaged valve.

The Model VM7000 is designed to

mount directly on safety valves and

rework nozzles up to 4 inches (101.6

mm) in diameter. The VM7000 will

mount on Dresser Consolidated

Maxi-Flow valves, orifice sizes 1

through 6, and on many

Crosby Safety Valves.

By eliminating downtime and

spare valve inventory costs,

you can probably pay for the

Model VM7000 by repairing just a

few valves in-line.

VM8000

Repair corroded seal areas on-site

with the valve in-line.

The VM8000 is designed for on-site

remachining of seats and seal areas of

Fisher and Dresser Masoneilan (or any

other, similar type) control valves. The

machine mounts directly on the valve

and bores throat areas from 2.5 - 10

inches (63.5 - 254 mm) in diameter.

With the Model VM8000 Valve Repair

Machine, the repair operation consists of

removing the valve bonnet and stem

assembly,

applying a stainless

weld buildup in the valve seat and seal

areas and remachining to the

manufacturer’s original specifications.

The original in-line welds are not disturbed

and need no recertification.