Climax CM6000 OBS CIRCULAR MILL User Manual

Climax Equipment

C M 6 0 0 0 C i r c u l a r M i l l

C M 6 0 0 0 C i r c u l a r M i l l

B r i n g i n g t h e s o l u t i o n t o y o u .

B r i n g i n g t h e s o l u t i o n t o y o u .

F e a t u r e s • s e t u p & O p e r a t i O n

C O m p O n e n t s & a C C e s s O r i e s • t e C h n i C a l D a t a

Portable, On-Site Machining Solutions

for Wind Tower Fabrication

april, 2010

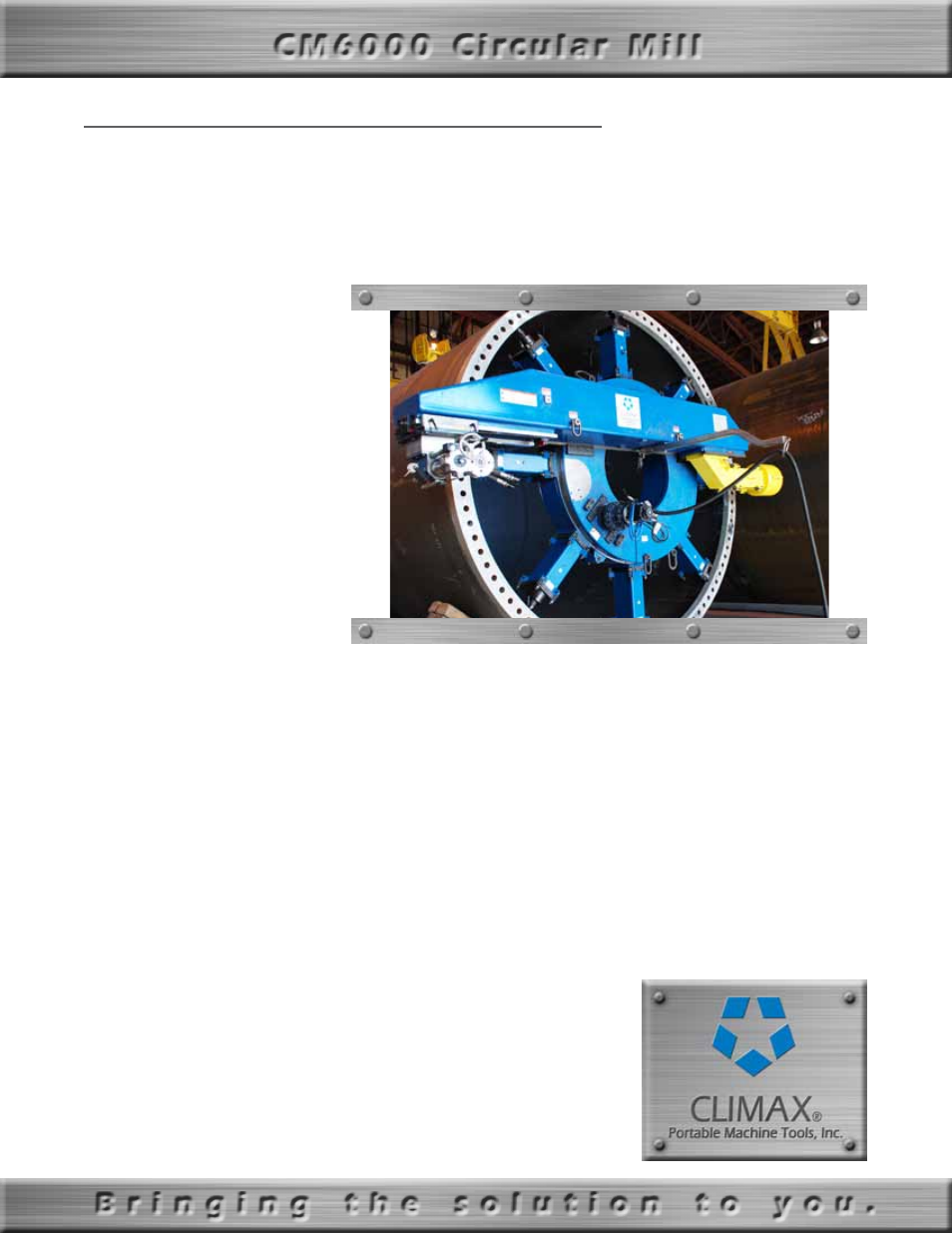

Climax circular mills deliver fast,

versatile machining to meet

demanding wind tower specifications

for connection flanges.

Three-axis milling head adjustments

allow the machinist to meet taper

and flatness specifications

simultaneously. The Climax CM6000

mounts easily into tower sections in

production or in the field, finished or

rough. With the CM6000, you deliver

accurate, precise tower sections,

ready to assemble at the job site.

Rapid Setup and Operation

• By bringing the tool to the tower

section, you get the job done fast.

• The Climax Portable Circular Mill

can cut machining time up to

75% compared to single-point

machining, especially on diameters

over 78 inches (1981.2 mm).

• Faster machining means 3-4

flanges in a typical shift.

• Rigging system allows fast, easy

installation in horizontal or vertical

flanges.

• Portable: circular mill disassembles

into manageable parts for ease of

transport and setup.

Powerful and Precise

• The Climax Portable Circular Mills

use large diameter precision

bearings and adjustable way radial

slides for the most rigid machining

platform available.

• Rotary Tables are manufactured to a

surface flatness tolerance of 0.002

inches (0.051 mm), allowing the

machine to hold extremely tight

machining tolerances.

the Cm6000 can be configured to perform across a wide

range of flange widths, section sizes and power sources.

Call today and ask us how we can build the right circular

mill for your job.