Climax FF8000 PORTABLE FLANGE FACER User Manual

Climax Equipment

F F 8 0 0 0 P O R T A B L E F L A N G E F A C E R

B r i n g i n g t h e s o l u t i o n t o y o u .

Portable Machine Tools, Inc.

®

F E A T U R E S • S E T U P & O P E R A T I O N

C O M P O N E N T S & A C C E S S O R I E S • T E C H N I C A L D A T A

Versatile

•

Available in ID or OD mount styles.

•

Options include grinding heads, flat

surface mounting, and a mounting

and facing range of up to 10 feet

(3048.0 mm) in diameter.

•

Power supply hoses attach to the top

or bottom of the machine with a

rotary union for operation in

horizontal, vertical, or inverted

positions.

Rugged and powerful

•

Large volume hydraulic motor, or

two rotational drive air motors.

•

Produces accurate machining even

at the maximum turning arm

extension.

•

Large diameter, heavy-duty Timken

bearings support the turntable sec-

tion. The turning arms are large

cross-section tubes that provide rigid,

lightweight mounting for the tool

head.

•

Smooth rotation is ensured by the

adjustable counterbalance arm and

a set of weights provided with the

machine. Properly adjusted, the

FF8000 rotates at a uniform rate,

even when mounted in vertical

flanges.

•

Precise finishes with HSS or

carbide tool bits, even on stainless

steel. Finishes as fine as RMS 16 can

be produced with the optional

grinding head.

•

The turning arms mount on the

machine turntable in dovetail ways

for easy positioning.

•

The 8.0 inch (203.2 mm) travel radial

feed is pneumatically actuated.

•

The tool head/radial feed

mechanism mounts on dovetail ways

at the end of the turning arm, to

re-face to the edge of flanges that

have very little clearance around

them, or cut right up to a shoulder.

Rotating diameter is easily adjustable

in limited clearance applications.

•

The four-inch (101.6 mm) travel

vertical feed is manually controlled

during automatic radial cutting

operations, or may be pneumatically

controlled when cutting grooves or

cutting down vertical surfaces.

•

The tool holder also rotates up to

45° in either direction for cutting

chamfers or J-weld preps.

Get big flange faces back

in working condition - FAST!

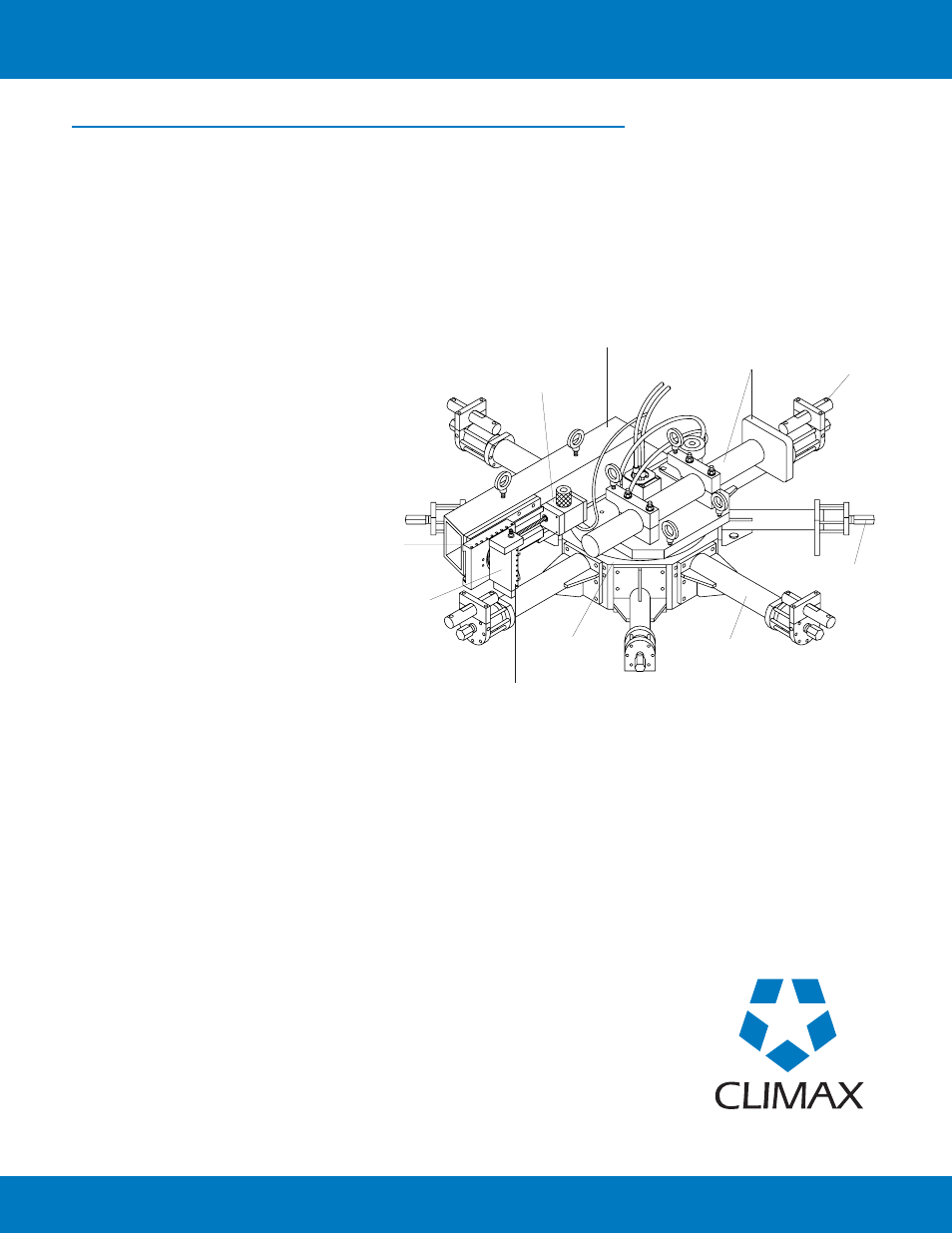

Set up fingers

Jacking bolts

Leg assembly

Main body

Vertical slide

Swivel tool

holder

Radial

slide

Feed box

Turning arm

Counterweight

and arm