27 problem solving (alarms & errors) 27, Problem solving 27, 29 problem solving (alarms & errors) – Franklin Fueling Systems Tank Sentinel (TS-1001, 2001, 504, 508 & 750) Setup Programming Guide User Manual

Page 166: Problem solving

Problem Solving

Page

29 - 1

29

29

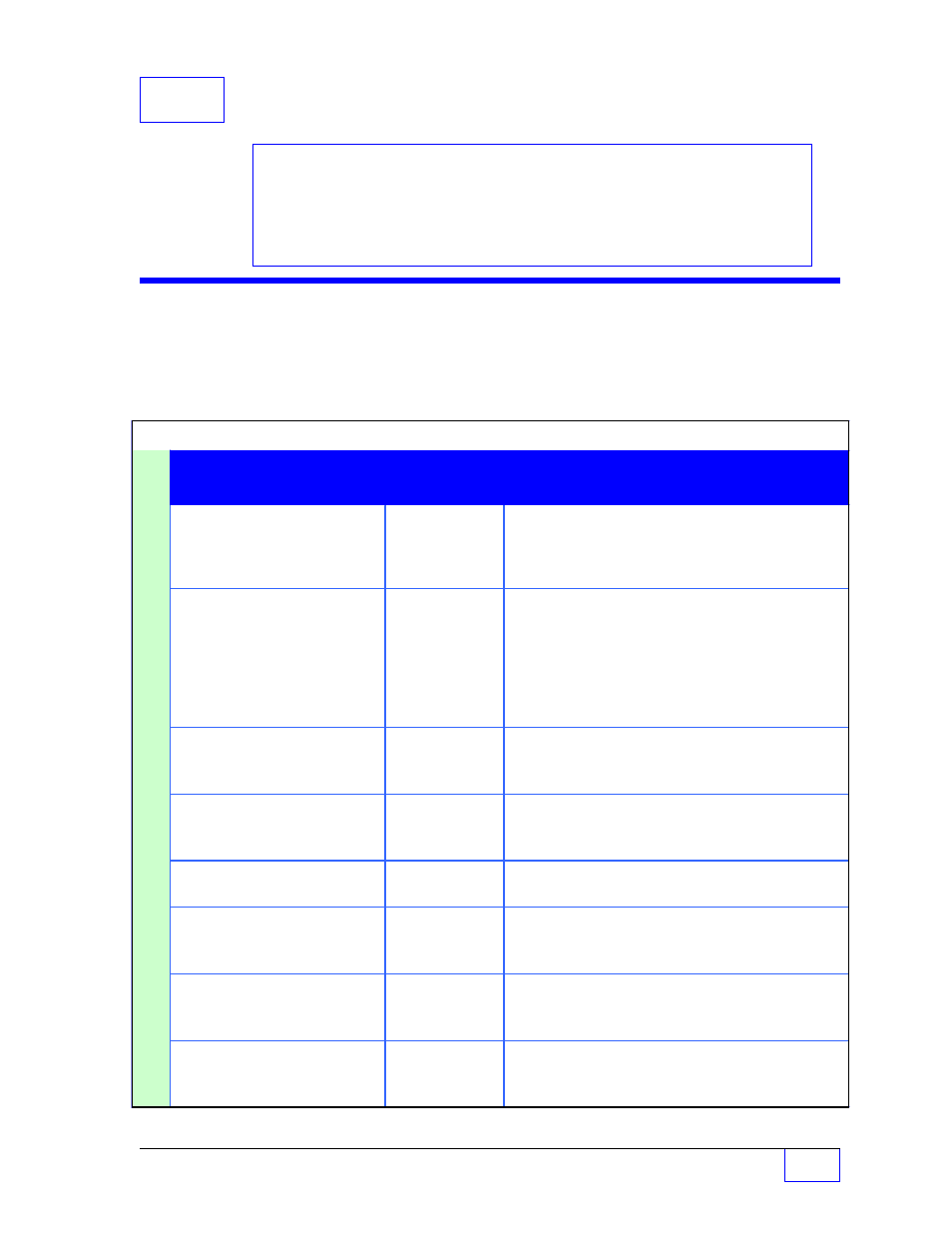

Problem Solving (Alarms & Errors)

Problem Solving

The following table lists alarms and errors in alphabetical order.

Notice they are

grouped by ‘Alarm Type’ in the middel section. Contact INCON for more help.

Contents:

Problem Solving

Outputs DON’T Turn On When

Expected

See the Table of Contents to find topics in

this manual. See the Preface for general

information about this manual. Also see the

Installation, Operator’s, TroubleShooting

Guides, and Application Notes for other

reference sources.

NOTE: Diagnostic text in the left column, is shown bolded { become alarms if active for 48 hours }

#

Printed / Faxed / Displayed

Alarm / Warning Text:

Alarm Type:

System WARNING / Error Descriptions and

ALARM Descriptions

(actions to take)

1

0.1 GPH LINE LEAK

DETECTED

LINE

For LINE # N: Line Leak Detected / Leak Test

Failed

(1. Inspect dispense area for leaks 2.

Retest if no leaks seen 3. Shut off pump /

dispenser power

2

0.1 GPH ABORT (DISPENSE)

LINE

Attempted dispense causes the annual line leak

test to aborted (dispensing is not allowed during

this test). To allow dispensing: push the RESET

/ TEST button on the TS-LLD Control Unit that is

flashing the 80 alarm-error-code.

See the TS-LLD

Quick Reference Guide about the 0.1 gph Annual

Test and requirements.

0.1 GPH LINE LEAK

(Continued… )

LINE

4. Second failure: Call Service provider / local

Regulatory Agency / Manager per policy

procedure at your site).

3

0.1 GPH LINE TEST

ABORTED

LINE

The annual precision line leak test was

intentionally canceled / aborted from the Tank

Guage or from the TS-LLD control unit.

4

0.2 GPH LINE LEAK

LINE

Follow the steps detailed above for 0.1 gph Line

Leak Detected

5

3 GPH LINE LEAK

LINE

LINE # N - Line Leak Detected / test failed Large /

gross leak

(see above 0.2 gph line leak & follow

steps 3, 1, and 4 in this order).

6

BLK TUB/LSU BLOCKED

TUBE

LINE

(Push RESET / TEST button on the TS-LLD

control unit that is flashing an 81 Alarm-error code

and call for cleaning service).

7

CU COMM/CU COMM

FAILURE

LINE

Communications was lost between the Tank

Sentinel console and TS-LLD Control Unit …(call

for service).