Bell & Gossett S13641B Technologic 5500 Series Pump Controller User Manual

Page 29

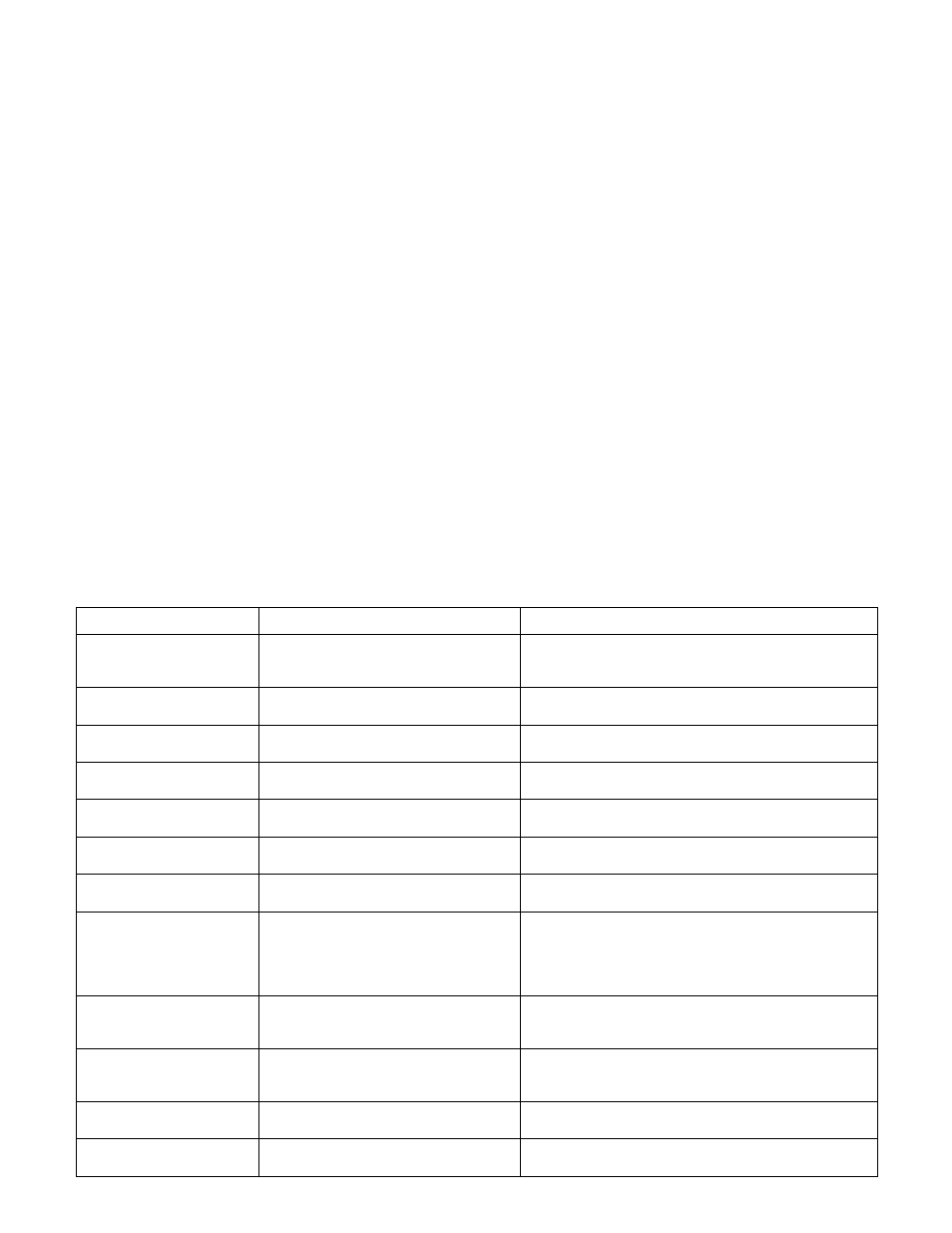

HELP SCREEN ALARM

HELP/HELP SCREEN DISPLAY

DETAILED DESCRIPTION

AFD Failure

“Check H-O-A switch, wiring , and

The controller is not receiving a closed run signal

AFD’s LED”

from AFD number X after it has been given a start

command

Battery Empty

“Check battery’s voltage and

Check for less then a 3V charge on the battery,

its continuity”

check battery connection

High Level

“Check setting of level switch”

Check for open or closed contacts, refer to

wire diagram for proper connection.

High Suction

“Check setting of the

Check for open or closed contacts, refer to

HIGH SUCTION switch”

wire diagram for proper connection

High System

“Check system pressure –

Check the pressure setting in the setup menu.

manual RESET required”

Low Suction

“Check setting of the

Check for open or closed contacts, refer to

low suction switch”

wire diagram for proper connection.

Low Level

“Check setting of level switch”

Check for open or closed contacts, refer to

wire diagram for proper connection.

NFSD

“System will restart automatically

For variable speed, check the Reset PV Drop

when flow occurs”

value and the pressure sensor connections,

refer to the wire diagram.

For constant speed, check the RTD connections,

refer to the wire diagram.

Overload Fail

“Check amp draw, Use manual reset

On Systems with Bell & Gossett bypasses the

if it’s OK”

controller is not receiving a digital input from the

pump number X starter confirming that it has closed

Pump Fail

“Check DP switch, impeller,

The controller is receiving a closed signal from

coupler, motor”

the differential pressure switch for pump number

X after it has been given a start command

Sensor Fail

“Check wiring, piping,

The controller is not receiving the proper 4-20mA

polarity, continuity”

signal from zone number X transmitter

Can IO Fail

“Check remote IO wire connection”

The controller has lost communication to the

remote IO rack

29

4.13.3

If you agree with the current setpoint settings press

the YES/7 key followed by ENTER. If you would like

to modify any of the setpoints press the NO/0 key fol-

lowed by ENTER at which point the setpoint in the

upper left portion of the screen will begin flashing.

4.13.4

Press the numeric key to modify the setpoint and

press ENTER to proceed to the next setpoint. Press

ENTER to advance to next zone without modification

or press CLEAR to return to the previous zone.

4.13.5

After modifying all of the zones press the ENTER key

until the “?” flashes, press the YES/7 key to accept

the values and return to the Technologic Pump

Controller screen.

4.14

PROCESS VARIABLE MONITORING

4.14.1

To view the actual process variable signals that are

being sent to the controller press the PROCESS

VARIABLE/1 key.

4.14.2

The following will be displayed:

PV1 = #

SP1 = #

PV2 = #

SP2 = #

PV3 = #

SP3 = #

PV4 = #

SP4 = #

For process variables the # symbol will be replaced

by the actual value. The display is updated con-

tinuously as the signal fluctuates. The units for the

numbers are defined in the sensor setup menu. The

source of the PV signal is also defined in the sensor

setup menu.

For setpoints the # symbol will be replaced by the

actual setpoint value. If the setpoint is defined by the

Technologic the number remains static. If the set-

point is supplied by an external device the number

will fluctuate as the SP signal fluctuates from the

controlling device. The source of the SP value is

defined in the communications setup menu.

4.15

ALARMS

4.15.1

When the controller detects an alarm condition, the

display will flash *ALARM* in the lower left corner of

the main screen.

4.15.2 The green LED on the HELP key will also flash during

an alarm condition. Press the HELP key for additional

information on the alarm(s). If there are more than

one alarm the alarms will be listed in order of

occurrence.

To view possible causes for alarms press the HELP

key again after the alarm is displayed.

Refer to table below for an overview of the possible

alarms and their respective causes.

4.15.3

Press the CLEAR key to return to the main screen.

After addressing the source of the alarm press

RESET to re-start the system and/or clear the alarms.

4.15.4

The controller logs alarms as they occur to aid in

troubleshooting unobserved alarms. Refer to Section

5.13 for alarm logging information.