2 list of maintenance works, Fig. b securing closing drive against opening – GE Industrial Solutions GERAPID 2607, 4207, 6007, 8007 with arc chutes 1X2, 1X4, 2X2, 2X3, 2X4 User Manual

Page 42

42

Design and specifications are subject to change without notice

S47183e rev.03 2010-06-07

6.2 List of maintenance works

TYPE OF THE WORK

BY WHOM

WHEN REQUIRED

RECOMMENDATIONS

A. Arc chute changing

-Customer

-Trained technician

As a result of the inspection C

B. Arcing contact and arc

runners changing

-Customer

-Trained technician

As a result of the inspection C

Replace complete arcing set.

C. Protective walls changing

-Customer

-Trained technician

As a result of the inspection C

D. Adjustment of the

contacts

-GE Service Engr

As a result of the inspection C

Only when replacement of the arcing

contact results with incorrect gaps.

See point 6.1.5.

E. Replacement of the

control board

-Customer

-Trained technician

As a result of the inspection B,E

F. Adjustment of the

mechanism

-GE Service Engr

As a result of the inspection B,E

G. Flexband or fixed contact

changing

-GE Service Engr

As a result of the inspection C,E

H. Mechanism changing

-GE Service Engr

As a result of the inspection B,E

I. Dumper(s) changing

-GE Service Engr

As a result of the inspection E

Replace upper and lower dumper at

the same time.

J. Trip unit changing &

adjustment

-GE Service Engr

As a result of the inspection B,E

K. Auxiliary contacts

adjustment and changing

-Customer

-Trained technician

As a result of the inspection B,E

In case of improper operation of the

switches, adjustment might be

necessary.

L. Drive changing

-GE Service Engr

As a result of the inspection B,E

M. Accessories changing

-GE Service Engr

As a result of the inspection B,E

Table 4

Required tools:

•

Cleaning tissue

•

Pocket lamp

•

Hand lever

•

Hexagon wrench SW 4, SW 5, SW 6

•

Screw wrench SW 10, SW 13

•

Torx® wrench size 30, 40 and 45

•

Small and medium screwdriver

•

Pliers

•

Wire cutter

•

File

•

Steel brush

Safety hints:

Securing against falling parts

Hint 1 Place a cloth into the lower area of the arcing

contact [Fig. a]. Remember to secure the closing drive

according to Hint 3.

Fig. a Protecting of the arcing area against falling parts

Maintenance with zero voltage release

Hint 2 If an optional zero voltage release is installed, it

must be energized to enable closing of the breaker. Only

then maintenance of the arcing contacts is possible.

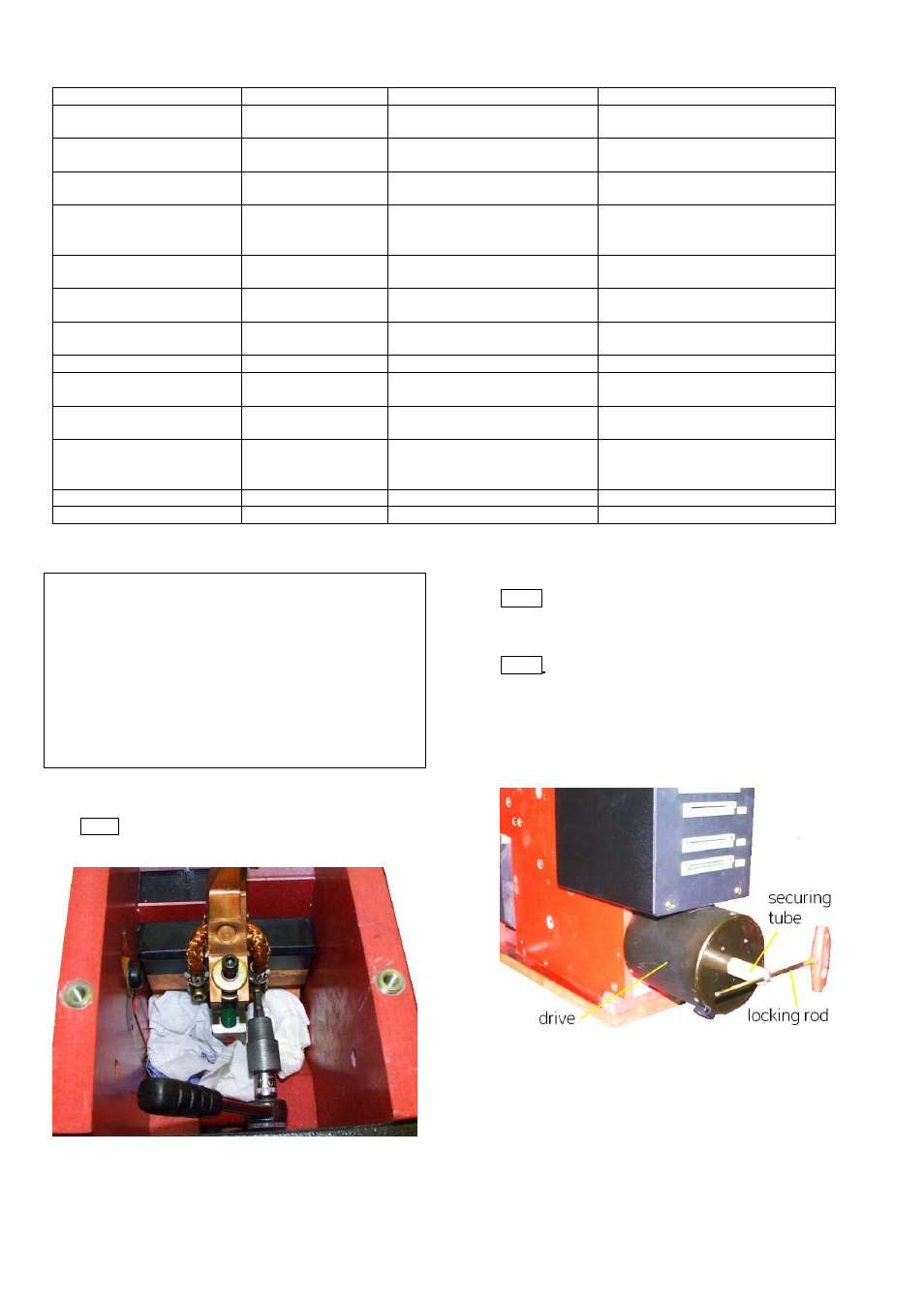

Hint 3 To prevent the risk of injury, it is recommended

to secure the breaker in the closed position with a simple

mechanical interlock device [Fig. b]. A piece of tubing

having ~50 mm [~2 in] length and inner diameter of

minimum 14 mm [0,55 in] works well. The outer diameter

of the locking rod shall be less 8 mm [0,3 in]. GE does not

offer this locking device.

Fig. b Securing closing drive against opening