Inspections and maintenance, 1 list of inspections, Type of the inspection – GE Industrial Solutions GERAPID 2607, 4207, 6007, 8007 with arc chutes 1X2, 1X4, 2X2, 2X3, 2X4 User Manual

Page 38

38

Design and specifications are subject to change without notice

S47183e rev.03 2010-06-07

6. Inspections and maintenance

6.1 List of inspections

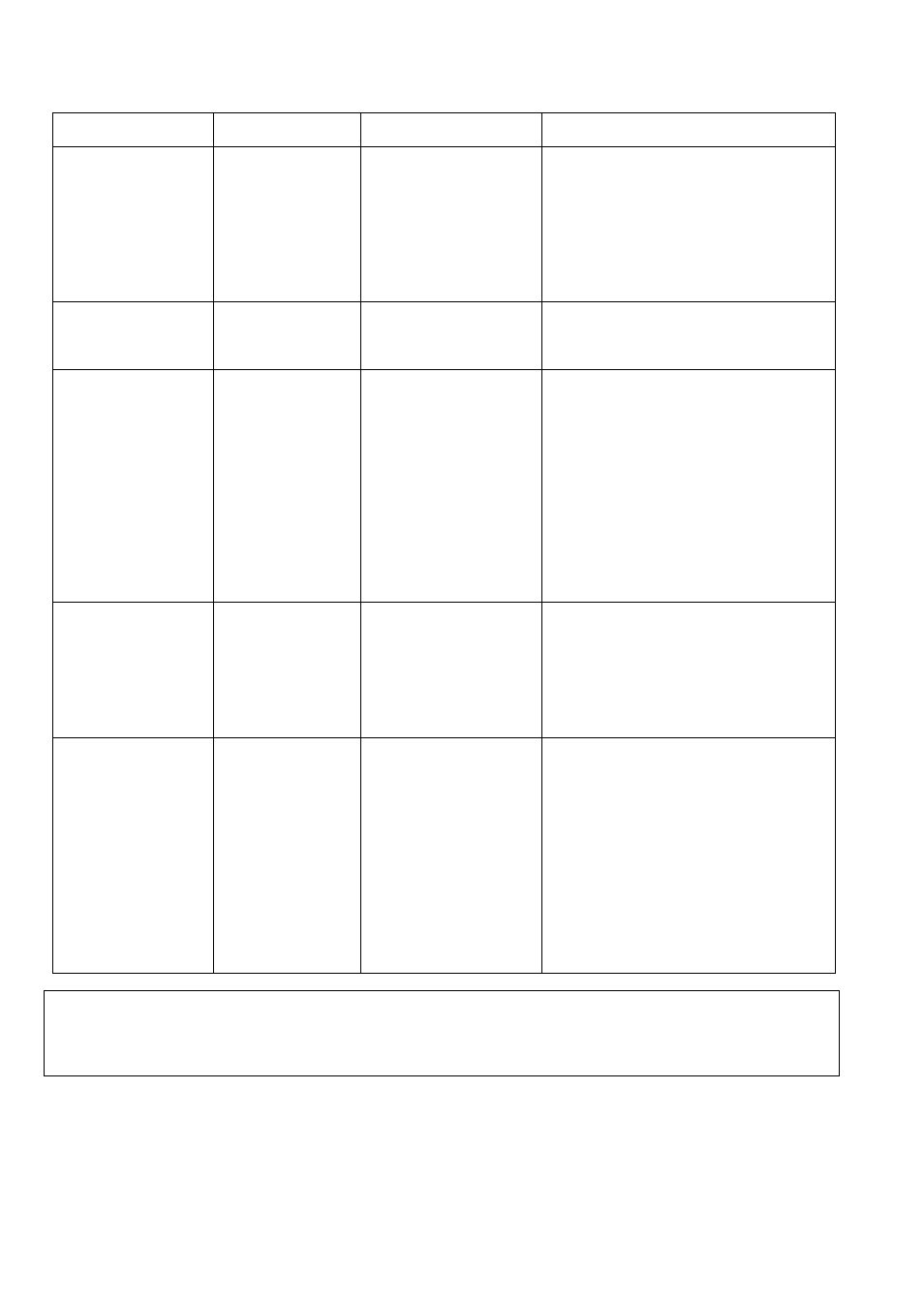

TYPE OF THE

INSPECTION

BY WHOM

HOW OFTEN

WHAT TO DO/CHECK

A. General visual

inspection

-Customer

-Trained technician

Every 6-12 months

•

Check for damages or cracks of the

frame, adapter or arc chute

•

Check for missing screws or caps

•

Check for damaged labels

•

Check for corrosion

•

Check for distinct manifestations of flame

or smoke at the frame

•

Clean the breaker from dirt and dust

•

Clean and degrease the copper terminals

B. General functional

inspection

-Customer

-Trained technician

Every 6-12 months

•

Manually close and open the breaker to

check the drive and mechanism

•

Close the breaker electrically and open by

trip unit(s) releasing, to check controls

C. Inspection of the arc

chute and contact

system

-Customer

-Trained technician

Every 6-12 months

or after:

•

high short circuit

opening at >25 kA

•

>300 openings at load

current

•

>100 openings at over

current load (2-3 x In)

It is recommend to carry

out inspection of contact

system after breaking of

equivalent of 150MA

2

s total

let through energy.

•

Check for wear of the arc runners; shall

not exceed 30 % of its cross section

•

Check for wear of the pre-arcing contact.

It shall not exceed 2 mm [0.08 in].

•

Check for wear of the main contacts at

fixed and flexible sides; shall not exceed

1.5 mm [0.06 in] of its depth.

•

Check for wear of the arc chute plates;

check for deposits inside of arc chute, this

area shall be free of deposits.

•

Check for wear of protective walls; shall

not exceed 1 mm [0.04 in].

•

Check for contact tilt and gaps.

D. Inspection of the

screw/bolt connections

-Customer

-Trained technician

Every 6-12 months

or after every inspection:

•

of the arc runners

•

of the contacts

•

of the arc chute

Check the position of the countersunk screws

in the sidewalls.

Check for tightness or use torque tool (torque

in SI and Imperial units):

•

M8 ~20 Nm [~ 177 in-lbs]

•

M6 ~10 Nm [~ 88 in-lbs]

•

M5 ~5 Nm [~ 44 in-lbs]

•

M4 ~3 Nm [~ 26 in-lbs]

E. Inspection of the

mechanic components

-GE

-Service technician

Every 5 years

or

After 5.000 openings

•

Carry out inspection “B” above

•

Check out settings of the main contacts

and auxiliary switch

•

Check out upper dumper of the

mechanism; no cracks, deformation or

heavy discoloration; hard consistency;

without punctures

•

Check out main flexband breakage; shall

not exceed 30 % of its cross section

•

Check out wear of mini flexband; shall not

exceed 30 % of its cross section

•

Clean and degrease UVR latch and quick

latch of the mechanism. Apply dash of

Beacon EP2 grease afterwards.

Required tools:

Cleaning tissue; abrasive paper; manual closing lever; hexagon wrenches SW5, SW6; Torx® wrenches size 30, 40, 45; small and

medium screwdrivers; ratchet with 10 mm hex cap; pliers; tongs.

Dispose of the breakers if required:

Pay attention to the national and local regulations of disposal!