GE Industrial Solutions AF-300 P11 User Manual

Page 57

5-4

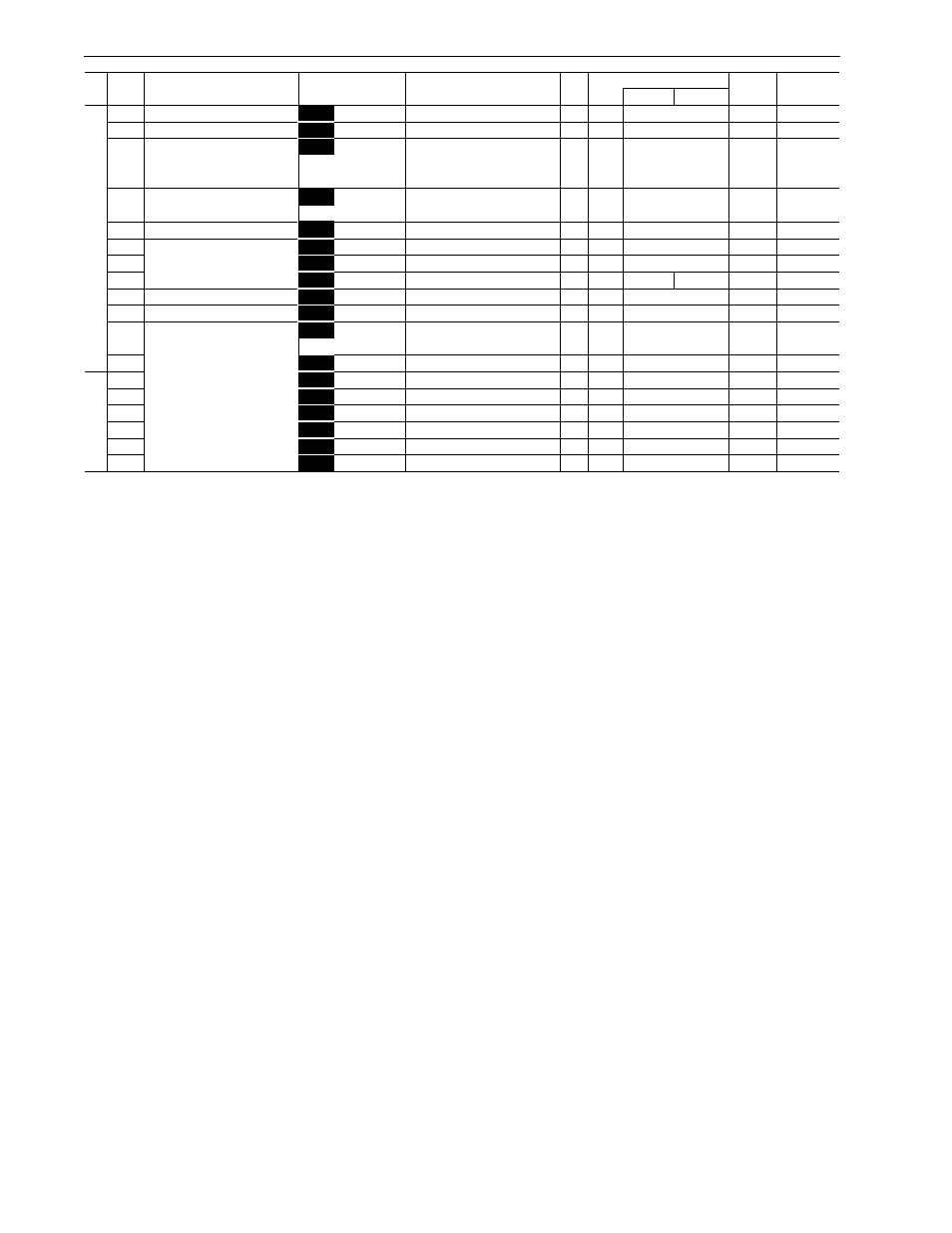

A: Alternative Motor Parameters

Pg.

Func.

Factory Setting

Data

Change

No.

Setting Range

Unit

Min.

30 HP

40 HP

Format

During op

A01

Maximum frequency 2

A01

MAX Hz-2

50 to 120 Hz

Hz

1

60

1

N

A02

Base frequency 2

A02

BASE Hz-2

25 to 120 Hz

Hz

1

60

1

N

A03

Rated voltage 2

A03

RATED V-2

0

V

1

230V class: 230

1

(at Base frequency 2 )

230V class:

80 to 240V

460V class: 460

460V class:

320 to 480V

A04

Maximum voltage 2

A04

MAX V-2

230V class:

80 to 240V

V

1

230V class: 230

1

N

460V class:

320 to 480V

460V class: 460

A05

Torque boost 2

A05

TRQ BOOST2

0.0, 0.1 to 20.0

-

-

2.0

3

Y

A06

Electronic

(select)

A06

ELCTRN OL2

0, 1, 2

-

-

1

1

Y

A07

thermal 2

(level)

A07

OL LEVEL2

20% to 135% if INV rated current

A

0.01

motor rated current

19

Y

A08

(thermal time constant)

A08

TIME CNST2

0.5 to 75.0 min

min

0.1

5.0

10.0

3

Y

A09

Torque vector control 2

A09

TRQVECTOR2

0, 1

-

-

0

1

N

A10

Number of motor 2 poles

A10

M2 POLES

2 to 14 poles

pole

2

4

9

N

A11

Motor 2

(capacity)

A11

M2-CAP

Up to 30 HP: 0.01 to 60 HP

HP

0.01

motor capacity

5

40 HP and above: 0.01 to 600 HP

A12

(rated current)

A12

M2-Ir

0.00 to 2000 A

A

0.01

motor rated current

19

N

A13

(tuning)

A13

M2 TUN1

0, 1, 2

-

-

0

21

N

A14

(on-line tuning)

A14

M2 TUN2

0, 1

-

-

0

1

N

A15

(no-load current)

A15

M2-Io

0.00 to 2000 A

A

0.01

standard rated value

19

N

A16

(%R1 setting)

A16

M2-%R1

0.00 to 50.00%

%

0.01

standard rated value

5

Y

A17

(%X setting)

A17

M2-%X

0.00 to 50.00%

%

0.01

standard rated value

5

Y

A18

(slip compensation control 2)

A18

SLIP COMP2

0.00 to 15.00 Hz

Hz

0.01

0.00

5

Y

N

N

5-45

Name

LCD Display

5-44