GE Industrial Solutions AF-300 P11 User Manual

Page 107

7-6

Data subject to change without notice 7/07. © 2007 GE Drives

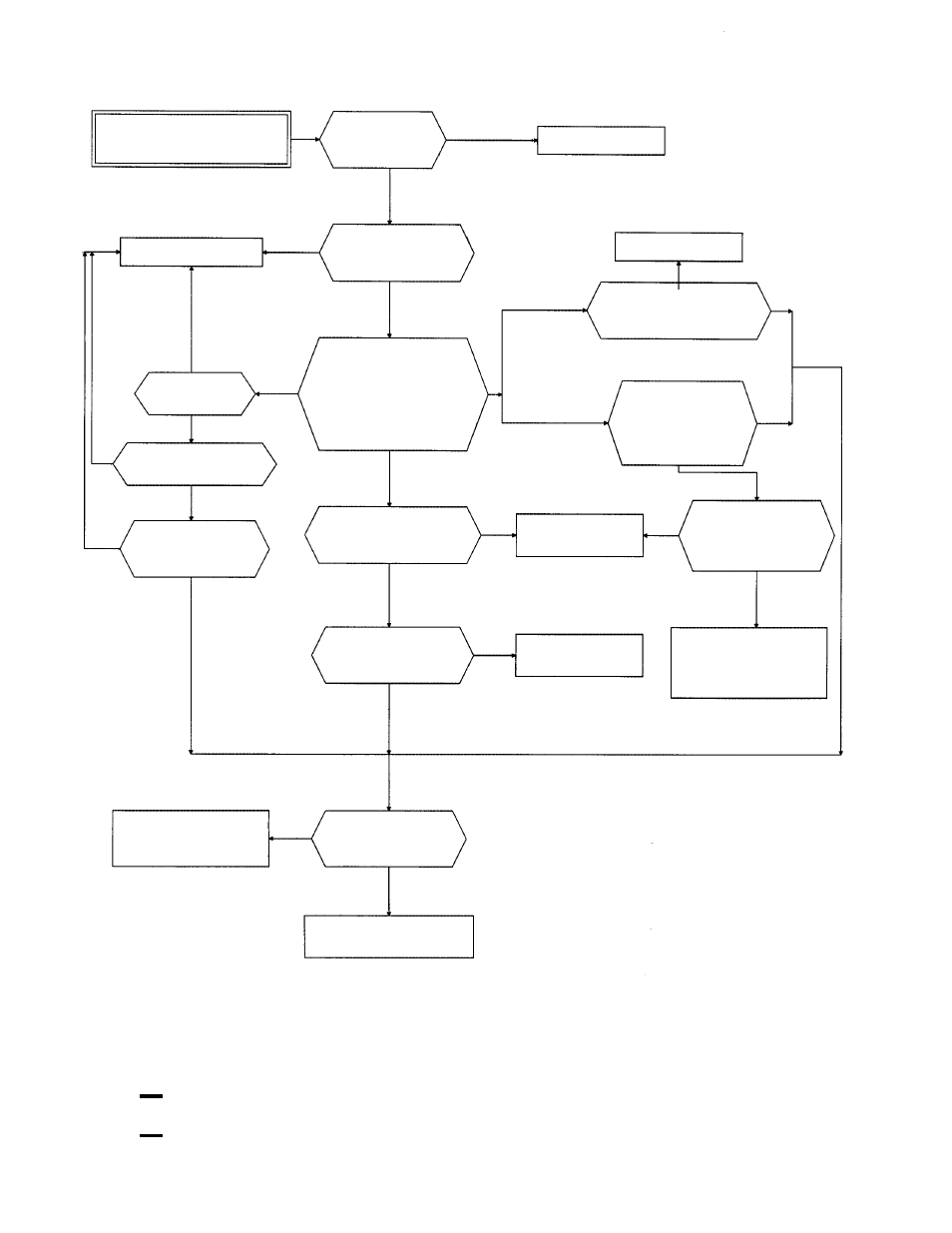

(2) If the motor rotates but the speed does not change

In the following cases, changing the motor speed is also restricted.

Signals are input from control terminals both 12 and C1 when “F01 Frequency command 1” and “C30

Frequency command 2” are set to 3, and there is no significant change in the added value.

The load is excessive, and the torque limiting and current limiting functions are activated.

The motor rotates but the

speed does not change.

YES

Change the setting.

Is the maximum

frequency setting too

low?

Is the higher or lower

frequency limiter

activating?

Is the timer timing

too long?

Which frequency setting

methods used: keypad panel,

analog signal, multi-step

frequency, or UP/DOWN

control? Is the pattern

operation activated?

Is the pattern operation

competed?

Are all acceleration and

deceleration times

identical?

Are the external connections

between X1-X9 and CM

correct?

Increase the setting.

Set the frequency.

Does the speed change when

the UP or DOWN is pressed?

Can the frequency

setting signal (0 to 10 V,

4 to 20 mA) be changed?

Correct the connection

error.

Replace the faulty frequency

setting POT (VR) or signal

converter as required.

YES

YES

Pattern

operation

Keypad panel

operation

Analog signal

Multi-step frequency

UP/DOWN

YES

NO

NO

NO

YES

YES

NO

NO

NO

YES

YES

NO

NO

NO

NO

YES

YES

Change the frequency

setting.

Are the external

connections between

control terminals 13, 12,

11 and C1 correct?

Are the frequencies for

each multi-step

frequency different?

Is the acceleration or

deceleration time set

too long?

Faulty drive or error

due to noise, etc.

Contact GE Drive.

Change the time setting to

conform to load values.

YES

NO